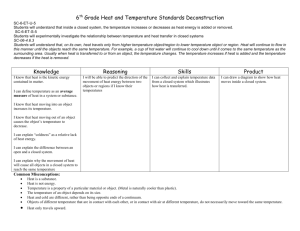

Now - Workforce Solutions

advertisement