Norwegian Advanced Instrumentation

advertisement

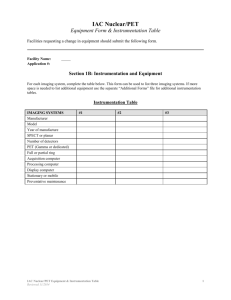

Advanced instrumentation 2006-2011 Outline of talk: Introduction (groups, competences, projects underway, infrastructure, related projects) Four sub-projects: 1. R&D for future silicon systems 2. The Norwegian technical student program at CERN 3. Support for an Industry Liaison with extended responsibilities related to Technology Transfer and recruitment 4. Participation in the CLIC accelerator R&D at CERN Summary Instrumentation for the future 1 Advanced instrumentation 2006-2011 Background : Traditionally around half of the students in the Norwegian program are instrumentation students – true also during LEP running due to the RDn programs at CERN Group competences and infrastructure; see next slides International projects underway (SLHC, CMB at FAIR, ILC, medical imaging); also in next slides In additon to having a very solid scientific program at LHC; to have more Norwegian CERN users at all levels must be the main goal for next period (this is also to be kept in mind for the ”physics” projects) The following subprojects are essential for our CERN exploitation: We now have around 10 technical students at CERN – program led by Jens Vigen with financial contributions from the Norwegian Research Council, with additional contributions from the Universities and University Collegues sending the students (Bergen, NTNU, SørTrøndelag mostly) We have temporarily an ILO (ex technical student from NTNU with one year background in the Technology Transfer area at CERN) covering several areas of interest for the general Norwegian CERN exploitation A student is interested in carrying out a ph.d projects in accelerator physics (CERN has asked for in-kind contributions to CLIC R&D) .... this person is finishing his Fellowship in ATLAS (Toroid system) Instrumentation for the future 2 Recent/on-going activities relevant for the future Five major technology activities related to CERN : Construction of silicon modules for ATLAS (UiB - Stugu, UiO – Stapnes/Dorholt, SINTEF earlier - Avseth, HiG at some level - Wroldsen). Key effort from the electronics and mechanical workshops in Oslo, partly true also for workshops at UiB PHOS detector for ALICE (UiB - Klovning, UiO - Skaali, AME earlier - Hansen) – note that AME and their technology development was strongly linked to CERN in 1980’ies for LEP Ongoing Construction of cryogenics tanks for ATLAS (NTNU-Owren, SB-verksted-Hansen, UiO partly-Stapnes) – technology transfer NTNU/SINTEF to SB-verksted, and reference contract with CERN Ongoing High Level Trigger development for ALICE (UiB-Rohrich and Ullaland, HiB-Helstrup, UiO-Skaali and Tveter) – high rates and high data-flow into readout and primary ”analysis” stage Completed successfully Completed succesfully RD50 (UiO – Svensson and SINTEF) – important and interesting R&D work for the future linked to new facilities in Gaustadbekkdalen Onging and very important Here you find all skills needed to construct any detector system, including readout and datahandling ... ___________________________________________________________________________________________________ Important note – worth mentioning in other talks (for a different audience) than this: This overview does not include ”the other half” of the Norwegian CERN activities related to physics studies, simulation of physics processes and detectors, pattern recognition, data-analysis, GRID, computing methods, statistical methods etc, etc ..... I refer to the talks earlier today Instrumentation for the future 3 RD50 - Radiation hard semiconductor devices for very high luminosity colliders 57 institutes (43 from EU) >250 scientists Particle Detectors – research lines @ UiO/PE • Defect and impurity engineering of high-resistivity Si • New materials; primarily silicon carbide (SiC) • Three-dimensional detector structures Jan-04 MRL (Oslo, Aug-2003) – 5000 m2 Equipment: • Characterization laboratories, etc • Electrical measurements; Probe station, C-V, DLTS, ADSPEC/TSCAP (20- 106 Hz) (cryostats 10-700 K, uniaxial stress), Laplace-&O-DLTS • Optical measurements; PL, interferometry, inverse photoemission • Scanning Nanoprobe -scopy (AFM, SSRM, TUNA, SCM); Foparken • SIMS & surface profilometer • MEMS-lab; etching, optical microscopes, etc MeV ion accelerator at UiO/MRL Ion implantation and RBS-analysis SIMS instrument at UiO/MRL National Electrostatics Corporation, 1 MV terminal voltage Instrumentation for the future 5 Electron microscope for e-beam lithography at UiO Equipment – Status Clean Room (Synthesis, processing and characterization) o Processing equipment (RTP, furnaces, evaporation, bonder, ....); o ALCVD-lab o Electron beam lithography (JEOL 6400F+ Raith-kit) (FUN/NanoMAT) o MeV implanter & Rutherford Backscattering Spectrometry (RBS) o Equipment from old SINTEF-lab is expected in late 2004 (early 2005) o JEOL model: JSM-6400F + ELPHI Quantum (Raith) Instrumentation for the future 6 SINTEF R&D for CERN projects: Partner (important) in infrastructure buildup in Gaustadbekkdalen – their sensor lab has been moved to same facilities RD-20, CERN 1992-1994 Dev.of High Resolution Si Strip Detectors for Exp.at High Luminosity at the LHC RD-48 (ROSE), CERN 1996-2000 Radiation Hardening of Silicon Detectors RD-50, CERN 2002 - Collaboration with UiO Development of Radiation Hard Semiconductor Devices for Very High Luminosity Colliders SINTEF very interested in 3D sensors (Andreas Werner) and this project; preparing a SFI application where 3D sensors is one sub-project. Instrumentation for the future 7 Advanced instrumentation – projects underway New R&D period underway internationally (traditionally the periods where the CERN technology exchange is the most interesting for us): For LHC upgrades (CMS and ATLAS have now R&D SG for upgrades with timescale 2014 ± 2 years The detector technology close to the interaction point needs new development (in fact, the IDs will be completely replaced). The ATLAS B-layer is foreseen to be replaced in 2012 and new sensors, more integrated approached, ”deeper” sub-micron, new power schemes will need to be developed. Driven by this plot, but also by lifetime of IR quads 700 fb-1 For linear collider detectors several R&D projects are ongoing and a conseptual design reports are foreseen by end 06-07 for accelerators and detectors: https://wiki.lepp.cornell.edu/wws/bin/view/Projects/WebHome Increased CERN R&D for medical systems over the next decade (EU projects), and Norwegian activities at CERN related to Technology Transfer agreements and medical instrumentations For heavy ions see later Instrumentation for the future 8 LHC detector changes ID changes In the current ATLAS/CMS trackers a factor ten luminosity increase would imply that the detectors die within months, and/or become useless due to increased occupancy creating problems for the tracking, and/or going beyond the acceptable readout rates. This applies to both PIXEL and Strip systems in ATLAS and CMS. The TRT in ATLAS will have an occupancy which approaches 100% and cannot be used. An other way of saying this is that the current technologies, with important new developments could work at a factor 3 higher radius. So we are looking at a full silicon tracker (the best current example is CMS) TRT barrel SCT barrel TRT endcap A+B TRT endcap C SCT endcap Pixels Instrumentation for the future 9 LHC detector upgrade Elements of new IDs ? Cost comparison for fixed volume 30.00 (65 $/chip) $/chip 25.00 20.00 025 013 unscaled 15.00 013 1/2 10.00 013 1/4 013 1/8 5.00 10,000 50,000 100,000 200,000 500,000 Electronics in DSM work well, parts already tested to 100 MRad (and more but not powered), ie 0.13um or 0.09um processes can do the job (CMOS or SiGe) - and costs are quite reasonable The lowest layers need special attention – even more true for sensors (make replaceable?) Yield/costs; ATLAS PIXEL chip has around 80% yield, production costs promising (but prototyping costs large – one iteration assumed in plot on the left) Volume required 10,000e 5000e Sensors: main issues are : Reverse currents rise. Trapping increases. Bulk type inverts to effectively p-type – depletion voltage increase. Consider to use p type bulk material to operate more effectively underdepleted, collection electrons (less trapping) For example: A conservative target for SLHC short strips would be survival of ~2 ×1015 cm-2 1MeV neutron equivalent, with S/N > 10 For PIXEL area more difficult, replaceable or 3D type (see RD50 studies for 1016 cm-2 1MeV neutron equivalent sensors) Both CMS and ATLAS have very good experience with sensor production and quality in current experiments For the innermost layer(s) special measures or replaceable system need to be considered – most significant R&D area Important R&D area: Very significant improvements in power distribution (serial powering or rad hard DC/DC) needed Instrumentation for the future 10 Advanced instrumentation – projects underway For ALICE running after 2012, there are a number of running options, the relative importance of which will depend on the initial results. Most probably this program will focus on rare probes and thus require higher luminosity and/or faster detectors and readout chains. A high-granularity silicon pixel detector, which is radiation hard and can be read out at high rates, is mandatory. QCD matter at large baryon densities is not sufficiently explored, neither experimentally nor theoretically. Nuclear reaction experiments at FAIR, the future facility at GSI (e.g. Compressed Baryonic Matter - CBM experiment) aim at a detailed and comprehensive investigation of superdense baryonic matter. The research program includes the measurement of penetrating probes, which escape essentially undistorted from the compressed nuclear collision zone. The planned Compressed Baryonic Matter experiment at GSI is a natural follow-up of the ALICE program. Important physics questions would include the production of heavy quarks in nuclear matter. Due to the low energies involved the rate would be low, and successful measurements would require high rate collisions and triggers, and corresponding high-speed detectors and readout chains So in both cases the following technologies/research fields are interesting: 3D silicon pixel detectors have electrodes that go all the way through the bulk of the material. This allows the electrodes to be positioned much closer together without the need to reduce the thickness of the detector, and thus the active volume. The close positioning of the electrodes is beneficial for both the full depletion voltage and charge collection efficiency. 3d detectors are expected to be radiation tolerant. However, reading out the fine-granular pixels with high-speed requires the integration of electronics component on the detector and the development of a new high-speed readout and onchip processing scheme in order to handle the huge data rate The DAQ concept will use selftriggered front-end electronics, where each particle hit is autonomously detected and the measured hit parameters are stored with precise timestamps in large buffer pools. Instrumentation for the future 11 Advanced instrumentation – CBM studies Vertex tracker (possible example of specs) : 700 μm material budget tolerable about 35 μm x 35 μm pixel size needed only a small part (50 cm2) is exposed to very high doses replacing this part after a major D run is feasible required dose and also interaction rate depends on D0 efficiency thin detectors (100 μm) require significantly less than thick (700 μm) ones fast readout allowing clear event association very valuable (at least) THUS WANTED: thin (<700 μm) high resolution (σ ~ 10 μm) fast (best <100 ns) radiation tolerant (30, better >100 Mrad) self-triggered, high bandwidth FEE Instrumentation for the future 12 International Research Training Group = Forskerskole ”Graduiertenkolleg” – ”Forskerskole” Starting date: 1.10.2004 Successful meeting at UiB in April with 30-40 participants, follow up now in September in Heidelberg, next meeting in Oslo in April Duration: 4.5 years – extendable by 4.5 years Funding DFG: 12 stipends + running costs UiB, UiO, HiB: a few stipends + 700 kNOK + ? Instrumentation for the future 13 IRTG - participants Instrumentation for the future 14 IRTG – research program Development and Application of Intelligent Detectors Includes • physics simulation • detector simulation • detector construction, system integration • readout design, development and operation • trigger design, development and operation • data handling and data management • online data analysis • offline data analysis • GRID computing Applies to • Nuclear Physics • High Energy Physics • Space Physics • Detector Physics • Sensoric • Microelectronics and Electronics • Computer Engineering • Computer Science Instrumentation for the future 15 Looming in the background: Prototype cardiology CdZnTe camera (IDEAS), and an X-ray camera (INTERON goal) – medical instrumentation Instrumentation for the future 16 Advanced instrumentation – proposed strategy Given the points discussed above the four sub-projects on page 1 have six main goals: Join forces to develop challenging new silicon technology taking advantage of knowledge base and new infrastructure in Norway Focus on basic technology development the first three years, related to 3D silicon sensors and new integration methods for sensors and electronics. Include a large number of students, in silicon detector system research using fully the link to “Forskerskole” students. Establish a new ILO and TT system where the focus is longer term and on technology transfer and knowledge, via projects and human resources spending time on CERN, in addition to the traditional CERN contract follow up. Strengthen the technical students program, and co-ordinate training of Norwegian students to provide an overall consistent environment for them where there is increased contact between the students, Norwegian CERN staff and researchers, and Norwegian Industries being involved in CERN projects. Participate in CLIC accelerator research to have a minimal activity in accelerator research, and also to answers CERN request for voluntary contributions to CLIC. Instrumentation for the future 17 Advanced instrumentation – R&D for future silicon systems As mentioned the overall research objective is to produce and characterize 3D silicon sensors – and to integrate transistors on the surface of these sensors. The production and characterization of the 3D detector itself will be done in collaboration with the MiNaLab in Oslo. The key steps are: Formation of 3D structures Annealing and passivation of process induced defects in 3D structures Formation of p-n junctions in the 3D detector structures Characterisation of detector The integrated electronics has to be added as a second processing round with an appropriate CMOS process. The main goals of the project are therefore (one iteration): Design and processing of 3D sensors In 2006 Design of electronics and evaluation First half 2006 Integrate electronics readout, transistor structures During 2006/early 2007 Evaluate in lab (3D sensors with test-electronics and During 2006, first half integrated devices) 2007 Irradiation tests and evaluation of results Towards end 2006 and during 2007 Evaluation of results Mid 2007 Instrumentation for the future 18 Schematics of 3D- and ordinary detector structures Proposed by S.I. Parker, C.J. Kenney and J. Segal (NIM A 395 (1997) 328) Called 3-D because, in contrast to silicon planar technology, have three dimensional (3-D) electrodes penetrating the silicon substrate Important researches are now under investigation by a collaboration (not in RD50) within Brunel Univ., Hawaii Univ., Stanford Univ. and CERN depletion thickness depends on p+ and n+ electrode distance, not on the substrate thickness (1) can operate at very low voltages or (2) can have a high doping for ultra-high radiation hardness Instrumentation for the future 19 Charge collection in 3D sensors lower collection length than planar technology lower charge collection time than planar technology higher charge collection efficiency computer simulations of the charge collection dynamics for planar and 3D detectors Instrumentation for the future 20 Real 3D devices a 3D detector structure: a 3D structure grown at SINTEF: 15 m 200 m 4 m Instrumentation for the future 21 Semi-conductor systems Trends to be noted – deep sub micron 8192 pixel cells/die 13 millions transistors/die 5 dies /detector Differential preamp Power/die:0.8W Pixel size:50 x 450 m All processing functions on cell ENC = 100 e- rms @ Cdet=0.1pF Threshold mismatch:150 e- rms Vdd=1.8V Filtering: 2 conjugate complex poles Beyond DSM processes (from CERN academic training) : 1. 2. 3. 4. 5. 6. Is there an end to CMOS Ultimate CMOS nanoscale technology Introduction to mesoscopic physics Quantum confinement, and electronic transport in nanowires Quantum dots and Single Electron Tunneling (SET) Transistor Nanoelectronic systems Instrumentation for the future 22 CERN and semi-conductor systems Trends to be noted – monolithic systems Motivation to develop a new pixel detector Radiation hardness improvement (leakage, reverse annealing issues) Decrease fabrication cost of pixel detector Develop a thin pixel detector Easy fabrication of large area devices Overcome readout limitation of Imaging architecture DEPFET MAPS Hybrid pixel Concepts of silicon pixel detectors in HEP(CCD excluded) 1st Hybrid silicon pixel 2nd DEPFET Monolithic on high resistivity substrate, bulk or SOI 3rd MAPS Monolithic on CMOS wafer substrate 4th concept not yet exploited deposition of detector material film on ASIC DEPFET pixel MAPS Instrumentation for the future 23 Semi-conductor systems Next steps Start 3D sensor development – can start now – will join forces/collaborate with US groups through ATLAS R&D projects Evaluate electronics/readout components to integrate, methods to do it, and partner for carrying out the electronics development – this project is less developed than the first Support and readout electronics, preparation for irradiations, etc can start right away too So basically this project can start immediately as soon as we have a funding base agreed Instrumentation for the future 24 Advanced instrumentation – Technical Students The Norwegian Technical student program is currently very successful and we wish to continue it. The ambitions are to keep it at the level of 10-12 students yearly. From an initial investment of support for 3-4 months the students are typically extended by CERN to 12 months, and even 14 months in some cases. The monthly cost is 3414 CHF, i.e 17750 NOK. The two Norwegian CERN staff members who have been doing most of the work have been Jens Vigen and Nils Høimyr, and they are willing to continue to promote the program. Jens Vigen will lead the sub-project. Contract signed in 2005 on the right Name Start Institutio n Support CERN Rune Andresen 16.01.05 NTNU 4 8 Håvard Bjerke 01.01.05 NTNU 4 3 Andreas Braathen 16.01.05 NTNU 4 8 Martin Bugge Jensen 01.03.05 NTNU 3 9 Magnus Lieng 16.01.05 NTNU 4 8 Thomas Johansen 16.04.05 HiB 3 9 Øyvind Østlund 01.05.05 HiB 0 12 Stian Erlend Førde 16.06.05 HiB 4 8 Camilla Stenersen 01.05.05 HiB 3 5 Christian Bråten 01.01.05 HiST 4 4 Thomas Rognmo 01.01.05 HiST 3 3 Edel Roedsjøsæther 01.01.05 HiST 3 9 Theodor Torgersen 01.07.05 HiST 0 12 Martin Handzus 16.01.05 HiM 3 9 Instrumentation for the future 25 Advanced instrumentation – ILO Based on the experiences from 2005 and a project study carried out by the Norwegian Research Council the following job-description seems appropriate to covers these tasks: Work as the Norwegian Industry Liaison Officer (ILO) Identify tenders at CERN that can be relevant for Norwegian companies and contact these companies Give support to the companies which want to receive an invitation to tender Participate in the negotiation between CERN and companies when this is needed Keep an active relationship with the technical department and the Norwegian staff at CERN to get Norwegian companies involved in the requirement specification process in forthcoming projects Attend to Norwegian technology and trade shows to promote CERN as a potential buyer of products and services Work as the Norwegian Technology Transfer Officer (TTO) Identify technologies developed at CERN which can be interesting for Norwegian companies Carry through marked researches for Norway on these technologies and contact the relevant companies Attempt to get Norwegian companies, research institutions and university into relevant pre-competitive R&D collaborations at CERN Attend to Norwegian technology and trade shows to promote CERN technology Work as an employment contact Function as a contact person for Norwegian CERN job applicants and for the Norwegian employment service (AETAT) Contribute in the recruitment and promotion work of CERN at Norwegian universities and university colleges with the purpose of increasing the number of students and scientist at CERN and increase the interest for in general Establish, maintain and update a Norwegian webpage about CERN Collect information from all the scattering webpages concerning CERN and streamline the information Information should be focused towards job applicants, students, researchers and the industry. Establish a transparent PTT (Project Tracking WEB system used at CERN) follow up of all parts of this project. This work will be carried out as a contract placed by this project. The contract will be annual, renewable up to 3 years Instrumentation for the future 26 Advanced instrumentation – accelerator physics The specific goal of this sub-project is to support a Norwegian activity, specifically a Ph.D grant, with the goal of setting up a test beam line to prove the feasibility of the CLIC drive beam RF power generation. The compact linear collider study at CERN aims to develop the technology for an electronpositron linear collider with a centre-of-mass beam collision energy in the multi-TeV range. The concept is based on a two-beam scheme in which the RF power to accelerate the main beam is not produced by klystrons but rather by a low-energy, high-current drive beam. This drive beam is generated centrally and transported to the main linacs. Here, it is sent through a sequence of Power Extraction and Transfer Structures (PETS) in which the beam generates the RF power for the main beam. This process leads to a strong deceleration of the drive beam, which in conjunction with the high current and low energy could affect the beam stability and the power production efficiency. In order to test the feasibility of the drive-beam generation and RF power production, the CLIC Test Facility 3 (CTF3) is under construction at CERN. It will also be used to benchmark the drive beam stability in the decelerator and compare experimental results with theoretical simulations. To this end, a Test Beam Line (TBL), which consists of a number of PETS, will be installed and tested with beam to produce up to 5 TWatts of RF power. The student will play a key role in the design of the TBL. He or she will model the beam conditions for different options of the PETS and TBL lattice. This study should lead to a choice of a specific PETS and lattice that allows to verify the predictions of the beam stability simulations. The work therefore includes the specification of the instrumentation. It is planned to build and test a prototype TBL PETS during the duration of the PhD project. CTF3 will run each year and provides the opportunity of participation in the test program allowing the student to gain experience in machine operation and the actual performance of the different hardware components. The student needs to work in close collaboration with experts in different fields, in particular accelerator operation, accelerator physics, beam diagnostics and RF. Instrumentation for the future 27 Organisation This project will be run as four independent subprojects with the following structure: Silicon part: UoO centrally: Ole Dorholt, MiNilab: Bengt Svensson, UoB: Kjetil Ullaland. Techncial students: Jens Vigen. ILO: Steinar Stapnes executes the contracts in close co-operation with the Norwegian Research Council (for detailed mandate, budget framework and reporting) CLIC: Steinar Stapnes supervises Erik Adli. For the International Research Team: Dieter Roehrich and Bernhard Skaali will act as main contacts at UoB and UoO, respectively. The people mentioned above, including the ILO and specific resource persons as needed connected to the project, will formally meet at least twice a year to review the status, plans and progress, and to co-ordinate the efforts. In this process we will draw in people involved in the CERN technology transfer program in order to support Norwegians activities and industries taking part. One way to do this is steer a few technical students at CERN into such project. All together aim of this project is create a common meeting place for University researchers, and industry partners involved in CERN related technologies and instrumentation projects. The project will be lead by Prof. Steinar Stapnes, UoO, and have as deputy leader Prof. Kjetil Ullaland, UiB. Instrumentation for the future 28 Participants Not a closed project: Welcome and expert other people to participate Instrumentation for the future 29 Conclusions The overall project is well based given experience, expertise and infrastructure The timing is good for R&D with respect to a number of future projects We integrate all the technical CERN related projects to improve communication and collaboration – something new in the Norwegian programme The resources are currently too small to do enough concerning integration of electronics – need to work with partners abroad and plan this in more detail next Would benefit the project very significantly if we could find decent support for Norwegian “Forskerskole” grants Instrumentation for the future 30