Production cum Costing Planner I desire to work in an organization

advertisement

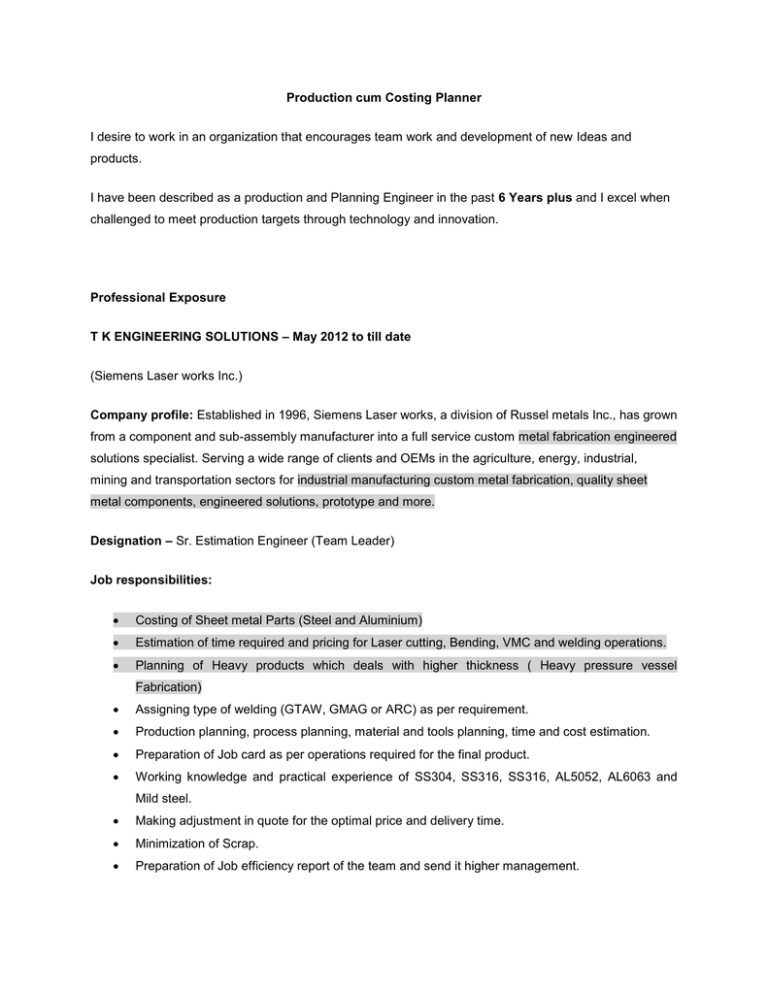

Production cum Costing Planner I desire to work in an organization that encourages team work and development of new Ideas and products. I have been described as a production and Planning Engineer in the past 6 Years plus and I excel when challenged to meet production targets through technology and innovation. Professional Exposure T K ENGINEERING SOLUTIONS – May 2012 to till date (Siemens Laser works Inc.) Company profile: Established in 1996, Siemens Laser works, a division of Russel metals Inc., has grown from a component and sub-assembly manufacturer into a full service custom metal fabrication engineered solutions specialist. Serving a wide range of clients and OEMs in the agriculture, energy, industrial, mining and transportation sectors for industrial manufacturing custom metal fabrication, quality sheet metal components, engineered solutions, prototype and more. Designation – Sr. Estimation Engineer (Team Leader) Job responsibilities: Costing of Sheet metal Parts (Steel and Aluminium) Estimation of time required and pricing for Laser cutting, Bending, VMC and welding operations. Planning of Heavy products which deals with higher thickness ( Heavy pressure vessel Fabrication) Assigning type of welding (GTAW, GMAG or ARC) as per requirement. Production planning, process planning, material and tools planning, time and cost estimation. Preparation of Job card as per operations required for the final product. Working knowledge and practical experience of SS304, SS316, SS316, AL5052, AL6063 and Mild steel. Making adjustment in quote for the optimal price and delivery time. Minimization of Scrap. Preparation of Job efficiency report of the team and send it higher management. Continuous monitoring of in-process & final production activities for reducing of nonconformance product. Assist various other international offices of the company in managing their projects and meet deadlines Oceaneering International Limited - Oct 2009 to till May 2012 Company profile: Oceaneering is a global oilfield provider of engineered services and products, primarily to the offshore oil and gas industry, with a focus on deep water applications. The company has their own ROV’s which works undersea/sub sea mainly to support oil company’s pipelines worldwide. We work/support on the technical issues reported by the offshore team on the ROV devices. Based on the issues reported, we create scenarios on simulator and help the crew in resolving the same by providing them with accurate solutions. We also provide trainings to the new recruits to operate the ROV in offshore. Designation – ROV Engineer Job responsibilities: Material Estimation and Costing of the Sheet metal parts and indent the same. Supervision of CNC Cutting, Welding and Bending Operation. Performing Required Operations with different parameters on ROV Simulator. Give training of ROV Piloting to newly hired ROV Supervisor on Simulator. Frequent visits to Kakinada, Singapore and Indonesia for queries related to production house. SPRAY ENGINEERING DEVICES LTD (July 2007 to Oct 2009) Company Profile: Spray Engineering Devices Limited (German Collaborator) has 12 years of expertise in designing and manufacturing sugar processing plant and equipment for local and international clients. With R&D being the core, SEDL uses best combination of Designs, Material, Manufacturing Technology and Automation Systems to engineer most efficient Process Equipment & Systems. SEDL has acquired a unique position in the Sugar Industry as Equipment Manufacturing Company with Energy Efficiency as the major Thrust Area. It serves more than 500 sugar factories globally. SEDL being a purely fabrication industry manufactures energy saving equipments like Cigar, Melter, Juice Heaters, Continuous Batch Pans, Condensers, Spray Ponds & Jet Nozzles. Designation - Engineer Job responsibilities: To design & develop different structures for cutting using CAM software- Logo tag & Plate ’N’ Sheet. Programming the CNC Plasma Cutting Machine for jobs of different geometrical shapes using CAM software-Magic Tool. by making optimum use of the material. Performing Quality checks to TIG and MIG Welding. Supervision of entire cutting and operation. Production Planning, process planning, material and tools planning, time and cost estimation and subcontracting To draw fabrication drawing (Link between Design department & Production department) EDUCATION B.Tech. Mechanical - Beant College of Engineering and Technology (Gurdaspur) Score- 70% (May2007) Academic Projects - Worked on Major Project “AIR –H2O” at college level. Industrial Training - 6 months industrial training in Maruti Suzuki Gurgaon (R & D department) - 6 and ½ week Industrial Training in Punjab Tractor Limited Mohali Primary and Higher Secondary – Kendriya Vidyalaya, Shimla Score - 60% Class X (C.B.S.E.) - 68% Class XII (C.B.S.E.) Personal Profile Father's Name Mr. Jiwan Singh Sandal Date of Birth 15th Sep, 1985 Sex Male Marital Status Single