Summary - Chapter 2

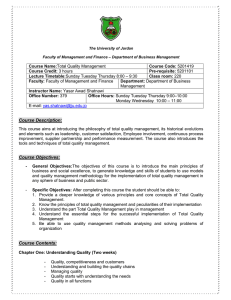

advertisement

Chapter 2: Total Quality Management (TQM) In this chapter, we have discussed about total quality management in the healthcare industry. In the past two-three decades, many companies throughout world have been under tremendous pressure some of them battered by international competitors, some others by new entrepreneurial companies and others were seriously by new technologies which created alternative to their products and services. Some leading companies have changed rapidly. While some of the new companies become major players, other companies are still engaged in daily battles for survival and many companies arc disappeared. These companies found that all their radical restructuring, reengineering, downsizing many quality programs may have helped survive, but they do not have destructive quality advantages. Future of these companies will be determined by three key areas Alignment, Linkage and Replication. In terms of quality management these points may be continuous improvements customer focus anti value for every member organization. These are three key areas transforming the way to manage entire organization. TQM means the vast collection of philosophies, concepts, methods and tools being used throughout the world to manage quality. Initially in few countries TQM is also called as Total Quality control (TQC) Now TQM is universally accepted. TQM is mainly concerned with continuous improvement in all work, from high level strategic planning, decision making, to detailed execution of work elements on the production floor. It stems from the belief that mistakes can be avoided and the defects can be prevented. It leads to continuously improving results. in all aspects of work, as a result of continuously improving capabilities, peoples, processes, and technology and machine capabilities. Continuous improvements must deal with improving results, along with more focus on the improving capability to produce better results in the future. The five major areas of focus for capability improvement are demand generation, supply generation, technology, operations and people capability. While discussing about the elements of TQM we have seen that, for successful implementation of TQM, an organization must concentrate on the eight elements Ethics, Integrity, Trust, Training, Teamwork, Leadership, Recognition, and Communication. TQM has been coined to describe a philosophy that makes quality the drive force behind leadership, design, planning, and improvement initiatives. The eight elements can be divided in to four major groups according to their function. The first and overriding feature of TQM is the company’s focus on its customers. Quality is defined as meeting or exceeding customer satisfactions. The goal is to first identify and then meet customer needs. TQM recognized that a perfectly produced product has little value if it is not what the customer wants. Therefore, we can say that quality is customer driven. Another concept of the TQM philosophy is the focus on continuous improvement. Traditional systems operated on the assumption that once the company achieved a certain level of quality, it was successful and needed no further improvements. Traditionally, change for American managers involves large magnitudes, such as major organizational restructuring. The Japanese, on other hand, believe that the best and most lasting changes come from gradual improvement this is called as kaizen by the Japanese. Part of the TQM philosophy is to empower all employees to seek out quality problems and correct them. With the old concept of quality, employees were afraid to identify problems for fear that they would be reprimanded. Often poor quality was passed on to someone else, in order to make it someone else’s problem. The new concept of quality, TQM, provided incentives for employees to identify quality problems. Employees are rewarded for uncovering quality problems, not punished. TQM places great deal of responsibility on all workers. If employees are to identify and correct quality problems they need proper training. They need to understand how to as quality by using a variety of quality control toots, how to interpret findings, and how to correct problems. There are seven different quality tools like Flow Charts, Cause and effect Diagram, Scatter diagram etc. Some more elements of TQM discussed in this chapter are: Mistake-Proofing, Inspection, Stop in Time. TQM is a management philosophy that seeks to integrate all organizational functions to focus on meeting customer needs and organizational objectives. TQM views an organization as a collection of processes. It maintains that organizations must endeavor to continuously improve these processes by incorporating the knowledge and experiences of workers.