The importance of Lactobacilli in contemporary food and

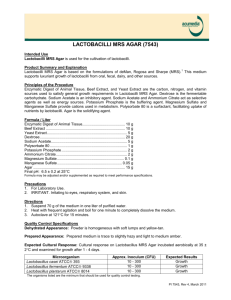

advertisement

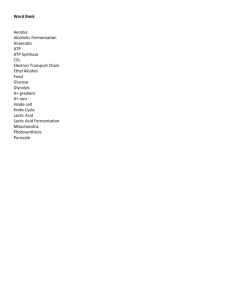

lactobacilli : Their Role and Importance in Contemporary Food and Pharmaceutical Industry Past-Present-Future Dr. Myrto -Panagiota Zacharof ¹ Dr. Robert W. Lovitt² ¹Multidisciplinary Nanotechnology Center, Swansea University, Swansea, SA2 8PP, UK ² College of Engineering, Multidisciplinary Nanotechnology Center, Swansea University, Swansea, SA2 8PP, UK lactobacilli and their Industrial Importance • lactobacilli are Gram positive (+) bacteria, shaped as rods which belong to the group of LAB. • They are natural habitants, rapidly colonising mammalian mucosal membranes such as oral cavity, intestine and vagina. • They are found where rich carbohydrate sources are available such as plants and materials of plant origin for example sewage and fermenting or spoiled food (Bernardeau et al., 2006). lactobacilli and their Industrial Importance • lactobacilli may affect the quality, flavour, odour and texture of the final product in either a favourable or a detrimental way (Cutting, Carr, & Whiting, 1975). • The genera important members of this group are Lactobacillus, Leuconostoc, Pediococcus and Streptococcus. • lactobacilli are also considered to be probiotic bacteria. Probiotics are live microorganisms that exhibit beneficial effects on the host’s health beyond inherent basic nutrition (Rose, 1978). lactobacilli and their Industrial Importance • lactobacilli fill in the major criteria that a microorganism should meet to be considered as a probiotic. • lactobacilli have proven to be effective against intestinal inflammation, maintenance of remission in Chron’s disease, treatment of infections during pregnancy, prevention of urinary tract infections (Ahrne et al., 2005). lactobacilli and their Industrial Importance • lactobacilli distinctive ability is to produce lactic acid from carbohydrate sources, especially from lactose and glucose. • Many of them have been found to produce antimicrobial activity possessing molecules called bacteriocins. Application of lactobacilli in the Contemporary Food industry Starter Cultures of Lactic Acid Bacteria (LAB) • Nowadays, LAB are constantly used in the food process industry in the form of starter cultures (Ross et al., 2005). • lactobacilli are widely applied in the food industry as the acids they produce suppress pH below the growth range causing metabolic inhibition of most pathogenic bacteria (Gruger& Gruger, 1989). Application of lactobacilli in Dairy Industry • Lactic Acid Bacteria (LAB) especially lactobacilli are responsible for the formation of the microflora of most dairy products especially of cheese and fermented milk. • lactobacilli are important for flavour, colour and texture of dairy products through acidification due to lactic acid and of the metabolism of milk proteins. • The most commonly used species in dairy products are L.casei, L.helveticus, L.rhamnosus, L.lactis, L.curvatus and L.plantarum (Jack et al., 1995). Application of lactobacilli on Wine Industry • lactobacilli are also applied in wine industry both for grape and fruit wines, such as cider. • The organic acids existing in wine which are mainly malic and tartaric acid can be easily metabolised by lactobacilli (Board, 1983). • Malic acid is converted to lactic acid and carbon dioxide, this phenomenon is called malolactic fermentation which is extensively used for fruit wines maturation (Liu et al., 2003). Application of lactobacilli on nonbeverage food products of plant origin • lactobacilli are applied in the fermentation of sauerkraut that is the product of fresh cabbage, pickles and olive fermentation. • The starter culture for sauerkraut or pickles or olives production is the normal flora of cabbage or any of the other plants, in addition with L.plantarum and an amount of NaCl so to avoid the growth of pathogenic bacteria (Miller & Litsky, 1976). Application of lactobacilli on Pharmaceutical Industry Production of Lactic acid • lactobacilli catabolise glucose to pyruvate acid by the Embden-Meyerhof (EMP) glycolytic pathway and galactose by the Leloir pathway. • The pathways are connected via phosphate-6glucose which is the final end product in the Leloir pathway and through this form can enter the glycolysis pathway and be further converted to pyruvate acid (Davidson & Sittman, 1999). Application of lactobacilli on Pharmaceutical Industry Production of Lactic acid • Lactic acid or 2-hydroxypropanoic acid is an important chemical substance widely used in food industry and in pharmaceutical and cosmetics industry. • Another modern application is the use of lactic acid as a monomer participating in the synthesis of biodegradable homopolymers and copolymers, such as polylactide (Choi & Hong, 1999). Industrial Importance of Lactic Acid • Lactic acid can be produced into large amounts, biotechnologically, through fermentation process performed by bacteria such lactobacilli. The fermentation can be carried out in a variety of liquid or solid media. • Usually, the product of fermentation is a racemic mixture conglomerate mixture of D (-) - and L (+) – isomers but there are also strains which produce optically pure forms of one of the stereoisomer’s. (Martak et al., 2003). Application of lactobacilli on Pharmaceutical Industry The Production of Bacteriocins • Among the Gram positive (+) bacteria, the Lactic Acid Bacteria (LAB) have gained particular attention nowadays, due to the production of bacteriocins (Ross, Morgan &Hill, 2002). Application of lactobacilli on Pharmaceutical Industry: The Production of Bacteriocins • The use of bacteriocins in food industry especially on dairy, egg, vegetable and meat products has been extensively investigated. • Among the LAB bacteriocins Nisin A and its natural variant Nisin Z has been proven to be highly effective against microbial agents causing food poisoning and spoilage. Conclusions • lactobacilli are an important microbial group for the productions of numerous compounds. The bulk quantities of their biomass are needed in dairy industry and further research has to be performed so to enhance their potential use as natural bioreactor which can produce efficiently many products of commercial usage. References • • • • • • • • • • • • • Board, R. G., A Modern Introduction to Food Microbiology. 1st ed.; Blackwell Scientific Publications: 1983; p 150. Choi, J. H., Ng, H.Y., Effect of Membrane type and material on performance of a submerged membrane bioreactor. Chemosphere Journal 2007, 11, 1-7. Bernadeau M. Vernoux, J. P., ,Henri-Dubernet, S., Gueguen M.,, The Lactobacillus genus. International Journal of Food Microbiology 2007, 41, 103-125. Liu, S.Q. (2003). Practical implications of lactate and pyruvate metabolism by lactic acid bacteria in food and beverage fermentations. International Journal of Food Microbiology, 83, 115-131 Stanier, R.Y., Adelberg, E.A., & Ingraham, J.L. (1977). General Microbiology (4th ed.): Oxford, Macmillan Press pp:496-504. Gruger, A.; Gruger, W., Biotechnology, A Textbook of Industrial Microbiology. 1st ed.; Sunderland,Mass Sinauer Associates: 1989; p 29-108. Jack R.W. Tagg, J. R., Ray B. , Bacteriocins of Gram-positive bacteria. Microbiological Reviews 1995, 3, 171-200 Rose, A. H., Economic Microbiology :Fermented Foods. 1st ed.; Academic press LTD.: 1982; p 148-189. Ross, R. P.; Desmond, C.; Fitzerald, G. F.; Stantch, C., Overcoming the technological hurdles in the development of probiotic foods. Journal of Applied Microbiology 2005, 98, 1410-1417. Ahrne S. et al., lactobacilli in the intestinal microbiota of Swidish infants. Microbes and Infection Journal 2005, 7, 1256-1262. Miller, B. M. and Litsky, W. (1976) Industrial Microbiology, McGraw-Hill, NY. Liu X., Chung Y. K., Yang S.T. , Yousef A.G., Continuous nisin production in laboratory media and whey permeate by immobilized Lactococcus lactis. Process Biochemistry Journal 2005, 40, 13-24. Martak, J.; Schlosser, S.; Sabalova, E.; Kristofikova, L.; Rosenberg, M., Fermentation of lactic acid with Rhizopus arrhizus in a stirred tank reactor with a periodical feed and bleed operation. Process Biochemistry Journal 2003, 38, 1573-1583. Davidson V. L., Sittman D. B., Biochemistry, NMS Series. 4th ed., Lippincott Williams and Wilkins: 1999, p 280285. Aknowledgments Questions Email: M.Zacharof@swansea.ac.uk • • • • Dr. Paul Williams Dr. Ilseon Jung Dr. Marion Jones Dr.Karnika Ratanapongleka