Supplementary Material NOVEL CHIRAL IMIDAZOLIDINONES

advertisement

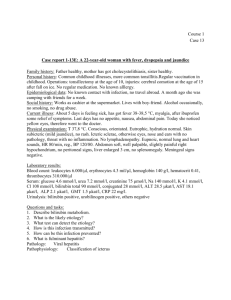

Supplementary Material NOVEL CHIRAL IMIDAZOLIDINONES SUPPORTED ON MAGNETIC NANOPARTICLES AS RECOVERABLE CATALYSTS Sara Mondini, Alessandra Puglisi, Maurizio Benaglia, Daniela Ramella, Carmelo Drago, Anna M. Ferretti, and Alessandro Ponti Synthesis of imidazolidinone 11 Ph H2 N O NH2 3 H 2N O 1 O O O O N Ph H Ph 3 O O O HO Ph N H 2 O N Ph H Ph 3 3 HO NH2 HO HO O O HO HO Ph O O N H HN O HO N Ph H Ph 3 O O N H HN 4 O NH2 3 5 O N O O N H O O N H N H 8 O N N O OH O O HO OH 6 H N HO 7 O O 9 O H N O OMs O H N O O 3 O OH 11 10 O H N N O Abbreviations Trityl chloride (TrCl), triethylamine (TEA), pyridine (Py), 1-hydroxybenzotriazole hydrate (HOBt), N-(3-dimethylaminopropyl)-N′-ethylcarbodiimide diisopropylethylamine (DIPEA), triisopropylsilane hydrochloride (TIPS), (EDC.HCl), trifluoroacetic acid N,N(TFA), methanesulfonyl chloride (MsCl), dichloromethane (DCM), N,N-dimethylformamide (DMF), diethyl ether (Et2O), diisopropyl ether (i-Pr2O); room temperature (RT). Synthesis of 5-(3-aminopropoxy)-N-trityl-pentan-1-amine (2). A solution of compound 1 (5g, 22.70 mmol) in DCM (250 ml) was added with TEA (0.475 mL, 3.41 mmol), the obtained mixture was stirred for 30 min and then cooled to 0 °C in an ice-bath. TrCl (632 mg, 2.27 mmol) was added in small portions. The reaction mixture was allowed to warm up to RT and left overnight. The organic phase was washed twice with a saturated solution of NaHCO3, dried with anhydrous Na2SO4, filtered off and finally, the solvent was removed under reduced pressure to afford 1.07 g of 2 (2.27 mmol, quantitative yield). 1H-NMR (400 MHz, CDCl3, 25 °C): δ = 7.43-7.37 (m, 6 H, aromatic protons Tr),7.23-7.17 (m, 6 H, aromatic protons Tr), 7.137.08 (m, 3 H, aromatic protons Tr), 3.58-3.41 (m, 12 H, CH2OCH2CH2OCH2CH2OCH2), 2.78 ( t, 2 H, CH2NH2 ), 2.20-2.11 (m, 2 H, CH2NH ) 1.76-1.63 (m, 4 H, CH2CH2NH2, CH2CH2NH). ESI-MS: m/z 463.5 [M+H]+. Synthesis of 2-[2-oxo-2-[3-[5-(tritylamino)pentoxy]propylamino]ethoxy]acetic acid (3). Diglycolic anhydride (527 mg, 4.54 mmol) and Py (0.736 mL, 9.08 mmol) were added to a solution of compound 2 in dry DMF (10 ml).The mixture was stirred for 16h at room temperature. Water was added to the crude then acidified with 5% citric acid to pH 5. The product was extracted with DCM, dried on anhydrous Na2SO4, filtered off and finally the solvent was removed under reduced pressure to achieve a practically pure compound 3. 1H-NMR (400 MHz, CDCl3, 25 °C): δ = 7.637.51(m, 5 H, aromatic protons Tr), 7.44-7.31(m, 10 H, aromatic protons Tr), 4.19 (s, 2H, CH2COOH), 4.13(s, 2H, OCH2CO), 3.55(m, 6 H), 3.52(t, 2 H,CH2NHCO), 3.45-3.35(m, 6 H), 3.2(t, 2 H, CH2NHCTr), 2.04(t, 2 H, CH2CH2NHCTr), 1.79(t, 2 H, CH2CH2NHCO). 13C NMR (400 MHz, CDCl3, 25 °C): δ = 138.8, 128.8, 128.7, 128.6, 71.3, 70.6, 70.5, 70.3, 70.1, 69.9, 69.4, 69.2, 45.4, 36.9, 36.3, 31.3, 28.7, 25.4 .ESI-MS: m/z 579.5 [M+H]+. Synthesis of 2-[2-[2-(3,4-dihydroxyphenyl)ethylamino]-2-oxo-ethoxy]-N-[3-[5(tritylamino)pentoxy]propyl]acetamide (4). EDC (154 mg, 0.801 mmol), HOBt (108 mg, 0.801 mmol) and DIPEA (0.458 mL, 2.676 mmol) were sequentially added to a stirred solution of compound 3 (426 mg, 0.736 mmol) in DMF (5mL).The reaction mixture was stirred at room temperature for 10 min until complete dissolution and then dopamine hydrochloride (127 mg, 0.669 mmol) was added. The reaction was left stirring until completion (evaluated by HPLC mass). Finally, the solvent was removed in vacuo and the crude product was purified by BiotageTM C18 reverse phase chromatography. BiotageTM eluant conditions: gradient from 90% H2O - 10% CH3OH-iPrOH(6:4) to 100% CH3OH-iPrOH (6:4). 286 mg, 0.399 mmol, 60% yield. 1H-NMR (400 MHz, CD3OD, 25 °C): δ = 7.46-7.40 (m, 6 H, aromatic protons Tr),7.29-7.21 (m, 6 H, aromatic protons Tr), 7.20-7.14 (m, 3 H, aromatic protons Tr), 6.68 (d, 1 H, catechol, Jorto= 8.3 Hz), 6.65 (d, 1 H, catechol, Jmeta= 1.7 Hz), 6.52 (dd, 1 H, catechol, Jorto= 8.3 Hz, Jmeta= 1.7 Hz), 4.00 (s, 2 H), 3.98 (s, 2 H), 3.61-3.51 (m, 8 H), 3.50-3.44 (m, 4 H), 3.41 (t, 2 H), 2.67 (t, 2 H), 2.25 (t, 2 H), 1.76 (qt, 4 H), 1.15 (d, 2 H). 13C NMR (400 MHz, CDCl3, 25 °C): δ = 129.7, 128.4, 127.0, 120.8, 116.6, 116.1, 71.3, 71.26, 71.22, 71.06, 70.99, 70.93, 68.6, 41.3, 40.5, 36.3, 34.5, 29.8, 29.0. ESI-MS: m/z 714.5 [M+H]+. Synthesis of N-[3-(5-aminopentoxy)propyl]-2-[2-[2-(3,4-dihydroxyphenyl)ethylamino]-2-oxoethoxy]acetamide (5). TIPS (0.070 mL, 0.336 mmol) and TFA (0.250 mL) were added sequentially to a solution of compound 4 (120 mg, 0.168 mmol) in DCM (5 mL). The obtained mixtures was left stirring for 2h at room temperature. Finally, the solvent was removed under reduced pressure. Water was added to the crude residue and extracted twice with i-Pr2O. The aqueous layer was removed and the resulting crude product 5 (95.3 mg, yield 82%) was sufficiently pure to be used without further purification. 1 H-NMR (400 MHz, D2O, 25 °C): δ 6.90 (d, 1 H, catechol, Jorto= 7.6 Hz) 6.84 (d, 1 H, catechol, Jmeta= 1.76 Hz), 6.75 (dd, 1 H, catechol, Jorto= 7.6 Hz, Jmeta= 1.76 Hz), 4.10 (s, 2 H), 4.03 (s, 2 H), 3.78-3.66 (m, 10 H), 3.62 (t, 2H), 3.53 (t, 2H), 3.30 (t, 2 H), 3.15 (t, 2 H), 2.78 (t, 2 H), 1.99 (qt, 2 H), 1.84 (qt, 2 H). ESI-MS: m/z 472.3 [M+H]+. Synthesis of methyl 4-(methylsulfonyloxymethyl)benzoate (7). Compound 7 was prepared according to a previously described procedure1. DCM (2 mL) was cooled to 0°C with an ice-bath. Methyl 4-(hydroxymethyl)benzoate (6) (50 mg, 0.301 mmol) and MsCl (0.26 mL 0.330 mmol) were sequentially added. After 5 min, TEA (0.1 mL, 0.65 mmol) was added dropwise to the reaction mixture which then was allowed to warm to RT and maintained for 4 h until complete consumption of the starting material (by 1H-NMR). The reaction was quenched with water (5 mL), extracted with DCM (3x10 mL), dried over anhydrous Na2SO4, filtered off and the solvent was removed under reduced pressure to afford crude 7 that was used without further purification in the next step. 1H NMR (CDCl3): δ = 8.03 (B part of AB system, 2 H), 7.43 (A part of AB system, 2 H), 4.62 (s, 2 H), 3.91 (s, 3 H), 3.16 (s, 3 H). Synthesis of 3-butyl-5-[(4-hydroxyphenyl)methyl]-2,2-dimethyl-imidazolidin-4-one (8). Compound 8 was prepared according to a slightly modified described procedure.2 (S)-Tyrosine methyl ester hydrochloride (3 g, 12.6 mmol) was added in one portion to a stirred solution of butylamine (4 mL, 40.3 mmol) and the obtained mixture was stirred at 25 °C for 24 h. The solvent was then removed under vacuum and the residue was treated with Et2O (20 mL). The resulting paleyellow solid was washed with another portion of Et2O (20 mL), filtered, and dried under vacuum. The crude product thus obtained was suspended in saturated aqueous NaHCO3 (10 mL) and stirred for 20 min. The resulting mixture was extracted with a 2% v/v solution of CH 3OH in CH2Cl2 (3 x 33 mL) and the organic solution was dried and concentrated under vacuum. The residue was dissolved in a mixture of CH3OH (15 mL) and acetone (25 mL) and PTSA (0.025 g) was added. The mixture was heated under reflux for 20 h and then concentrated under vacuum to afford a crude product that was purified by flash chromatography (CH2Cl2/CH3OH, 95:5). The pure product (3.31 g) was isolated in 95% overall yield. M.p. 99-101°C. [α]D23 = - 78.2 (c = 0.72 in CH2Cl2). 1H NMR (CDCl3/D2O): δ = 7.04 (B part of AB system, 3JH,H = 8.5 Hz, 2 H, aromatic protons), 6.74 (A part of AB system, 3JH,H = 8.5 Hz, 2 H, aromatic protons), 3.73 (t, 3JH,H = 5.8 Hz, 1 H, CHN), 3.29 (ddd, 2JH,H = 12.0, 3JH,H = 6.7, 3.2 Hz, 1 H, one H of NCH2), 3.04 (ddd, 2JH,H =12.0, 3JH,H = 5.8, 5.4 Hz, 2 H, ArCH2), 2.89 (ddd, 2JH,H = 12.0, 3JH,H = 6.2, 3.1 Hz, 1 H, one H of NCH2), 1.43-1.49 (m, 2 H,NCH2CH2), 1.21-1.31 (m, 2 H, CH3CH2), 1.27 (s, 3 H, CMe),1.17 (s, 3 H, CMe), 0.90 (t, 3JH,H = 7.3 Hz, 3 H, CH2CH3) ppm. 13C NMR: δ = 174.2, 155.8, 130.7, 127.2, 115.7, 76.4, 58.9, 40.4, 35.5, 31.3, 27.8, 26.3, 20.3, 13.7 ppm. IR: ν˜ = 3270, 1675, 1620 cm_1. C16H24N2O2 (276.4): calcd. C 69.53, H 8.75, N 10.14; found C 69.71, H 8.64, N 10.23. Synthesis of methyl4-[[4-[(1-butyl-2,2-dimethyl-5-oxo-imidazolidin-4- yl)methyl]phenoxy]methyl]benzoate (9). A solution of the imidazolidinone 8 (301 mg, 1.09 mmol) in dry DMF (1 mL), under nitrogen, was added with K2CO3 (410 mg, 3.3 mmol). Then, the obtained mixture was added with a solution of the mesyl derivative 7 (242 mg, 0.99 mmol) in dry DMF (1 mL). The reaction mixture was allowed to stir at 25 °C for 18 h. The solid crude product was filtered and purified by flash chromatography (CH2Cl2/CH3OH, 95:5). 260 mg (0.61 mmol, 62% yield). 1H NMR (CDCl3): δ = 8.08 (B part of AB system, 2 H), 7.52 (A part of AB system, 2H), 7.20 (B part of AB system, 2 H), 6.92 (A part of AB system, 2 H), 5.14 (s, 2 H), 3.96 (s, 3 H), 3.77 (t, 1H), 3.33 - 3.30 (m, 1 H), 3.10 - 3.06 (m, 1 H), 2.99 - 2.92 (m, 2 H), 1.59 - 1.50 (m, 2 H), 1.36 - 1.32 (m, 2 H), 1.31 (s, 3 H), 1.18 (s, 3 H) 0.95 (t, 3 H). ESI-MS: m/z 425.6 [M+H]+. Synthesis of 4-[[4-[(1-butyl-2,2-dimethyl-5-oxo-imidazolidin-4- yl)methyl]phenoxy]methyl]benzoic acid (10). A 2 N solution of LiOH (2 mL) was added to a solution of imidazolidinone 9 (254 mg, 0.6 mmol) in dioxane (10 mL) and the obtained mixture was left stirring at 25 °C for 18 h until consumption of the starting material (evaluated by TLC). The reaction mixture was cooled to 0°C and a 1N solution of HCl (5 mL) was added until pH = 4.5. The reaction mixture was extracted with ethyl acetate (3x10 mL). The organic layer was dried over anhydrous Na2SO4 and the solvent was removed under reduced pressure to afford the crude 10 which was used in the next step without further purification (245 mg, 0.6 mmol, quantitative yield). δ = 7.91 (B part of AB system, 2H), 7.35 (A part of AB system, 2 H), 7.27 (B part of AB system, 2 H), 6.80 (A part of AB system, 2 H), 4.71 (s, 2 H), 4.11 (bs, 1 H), 3.33 - 3.23 (m, 2 H), 3.23 - 2.97 (m, 2 H), 1.35 (s, 3 H), 1.33 (s, 3 H), 1.31 - 1.26 (m, 4 H), 0.95 (t, 3 H). ESI-MS: m/z 411.2 [M+H]+. Synthesis of 4-[[4-[(1-butyl-2,2-dimethyl-5-oxo-imidazolidin-4-yl)methyl]phenoxy]methyl]-N[3-[5-[[2-[2-[2-(3,4-dihydroxyphenyl)ethylamino]-2-oxoethoxy]acetyl]amino]pentoxy]propyl]benzamide (11). Imidazolidinone 10 (187 mg, 0.46 mmol) was dissolved in dry DMF (15 mL) and cooled to 0 °C. HOBt (65.5 mg, 0.484 mmol), EDC (90 mg, 0.46 mmol) and freshly distilled DIPEA (0.285 mL, 1.55 mmol) were sequentially added. The reaction mixture was warmed up to room temperature and amine 5 (200 mg, 0.4 mmol) dissolved in 2 mL of dry DMF was added. The reaction was allowed to stir at 25°C for 18h until consumption of the starting material (evaluated by HPLC mass). The solvent was removed under reduced pressure and the crude was purified by BiotageTM C18 reverse phase chromatography. BiotageTM eluant conditions: gradient from 90% H2O - 10% CH3OHiPrOH(6:4) to 100% CH3OH-iPrOH (6:4). 1H-NMR (400 MHz, CD3OD, 25 °C): δ 7.82 (B part of AB system, 2 H), 7.52 (A part of AB system, 2 H), 7.18 (B part of AB system, 2 H), 6.95 (A part of AB system, 2 H), 6.71 (s, 1 H) 6.67 (dd, 1 H), 6.53 (dd, 1 H), 5.14 (s, 2 H), 4.01 (d, 4 H), 3.75 3.71 (m, 1 H), 3.63 - 3.60 (m, 4 H), 3.59 - 3.50 (m, 4 H), 3.42 (t, 2 H), 3.35 - 3.23 (m, 2 H), 2.68 (t, 2 H), 1.89 (t, 2 H), 1.78 (t, 2 H), 1.55 - 1.45 (m, 3 H), 1.34 - 1.29 (m, 1 H) 1.28 (s, 3 H), 1.20 (s, 3 H), 0.94 (t, 3 H). 13 C-NMR (400 MHz, CD3OD, 25 °C): δ =131.0, 128.1, 127.9, 120.7, 116.5, 116.0, 115.7, 71.1, 71.1, 70.9, 70.8, 69.94, 69.90, 69.6, 60.1, 41.5, 40.9, 38.4, 37.3, 36.6, 35.5, 32.1, 30.0, 27.5, 25.8, 20.9, 13.7 ppm. ESI-MS: m/z 886.8 [M+Na]+. 1 H-NMR spectrum of compound 11. General procedure for the recovery and recycle of the catalyst . After the Diels-Alder reaction (see text) an external permanent magnet was applied and the aqueous layer was removed. (Et2O could be added to improve the precipitation of the MNPs). The nanoparticles were washed with Et2O (3x3ml) to completely recover the reaction products. Nanoparticles were then dried by purging with nitrogen and suspended in DCM (1 mL); TFA (3 eq ) was added and the mixture was shaken for 1h. Hexane (1 mL) was added to improve precipitation of nanoparticles; the supernatant was discarded and the catalyst was dried by purging N2. The reactivated catalyst was used in the next cycle. References 1 S. P. Govek, J.-M. Vernier, T. Kamenecka, J. H. Hutchinson, R. Pracitto, Patent WO2006091496, 2006. 2 A. Puglisi, M. Benaglia, M. Cinquini, F. Cozzi, G. Celentano Eur. J. Org. Chem. 2004, 567-573.