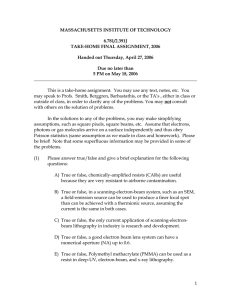

Slide 1

advertisement

Lithography NANO 101 Introduction to Nanotechnology 1 “Photoengraving” - Transfer pattern into reactive polymer film (“resist”) - Use resist to replicate pattern into thin film or substrate • • • • Photolithography Electron beam lithography X-ray lithography Focused ion beam lithography Lithography 2 • “Printing” • Transfer of the pattern using an optical technique • Resist = photoresist; photoactive polymer, positive or negative 1. Coat substrate with resist 2. Mask; expose with light 3. Develop (dissolve exposed OR unexposed areas with chemicals) 4. Etch unprotected areas or deposit layer of metal 5. Strip resist Photolithography 3 • Maximum resolution (minimum size) of individual features limited by diffraction Diffraction: • bending of light • around an edge • through a slit • past an object (edges) • direction changes • wavelength, frequency stay the same Photolithography 4 Photolithography Maximum resolution: 2bmin d 3 s 2 λ b s d 5 Three Modes of Photolithography http://www.ece.gatech.edu/research/labs/vc/theory/photolith.html 6 Photolithography: Shadow Printing • Contact mode: • s=0 • Best resolution; near 100% accuracy • Maximum resolution rarely achieved • Substrate and resist film rarely completely uniform • Proximity mode: • Small gap between mask and substrate • Need extremely flat substrates and resist films 7 Photolithography: Projection Printing Resolution • Worse resolution than shadow printing • Lens imperfections • Increased diffraction • type of resist material • optical system (apertures) • exposure wavelength (λ) • Best resolution ~ λ/2 8 Radiation with smaller wavelengths • Deep Ultra-Violet (DUV): λ < 300 nm • Need to use special lasers • Minimum pattern size ~ 100 nm • Extreme UV (EUV): λ = 11-13 nm • Minimum pattern size ~ 60 nm • Strong absorption of light by lenses • Low reflectance of light by mirrors 9 http://www.lcse.umn.edu/specs/labs/images/spectrum.gif Current State of EUV • Sustained 100W average source power • 1,000 wafers processed in 24 hrs http://www.extremetech.com/computing/199782-tmsc-announces-lithographymilestone-as-euv-moves-closer-to-production 10 Other Options: • ArF laser (193 nm) is current state of art Diffraction limit n = index of refraction n air : 1.0 n water: 1.3 – Immersion (change refractive index) – Double Patterning http://www.extremetech.com/computin g/190845-intel-forges-ahead-to-7nm11 without-the-use-of-euv-lasers Double Patterning http://willson.cm.utexas.edu/Research/Sub_Files/DoubleExposure/index.php 12 X-Ray Lithography • X-Rays • 0.04 nm < λ < 0.4 nm • System • Mask • X-ray absorbing material pattern on a thin X-ray transparent material • X-ray source • Bright enough in necessary wavelength range • Expensive • X-ray sensitive material 13 http://www.camd.lsu.edu/microfabrication/latech.htm LIGA • Lithography, Electroplating, Molding 14 http://sylmand.info/features/x-ray-lithography/ Electron Beam Lithography E-beam: – Finely focused beam of electrons (few nm dia.) – Electrons deflected accurately and precisely to “write” pattern without mask Resolution – Diffraction not an issue • λ < 1 Å (0.1 nm) – Scattering • Forward (in resist layer) • Backwards (substrate) http://nanotechweb.org/cws/article/tech/18642 15 Electron Beam Lithography System • Electron source (gun) • Electron column (forms beam) • Mechanical stage • Control Computer https://smif.lab.duke.edu/pict.htm 16 Focused Ion Beam (FIB) Lithography • Ions scatter much less than electrons • Sources: – Liquid metal ions (Ga; Au-Si-Be alloys) – Long lifetime, high stability • Resolution – sub-µm dimensions (~250 nm) – High resist exposure sensitivity – Negligible ion scattering in resist – Low back scattering from substrate • Extensive substrate damage • Also used for etching, deposition, and doping 17 Focused Ion Beam (FIB) Applications • Etching – Physical sputtering etching • Bombard areas to be etched with energetic ion beams • Simple, applicable to any sample material – Chemical etching • Chemical reactions between substrate surface and gas molecules adsorbed onto surface • Increased etching rate, little residual damage • Deposition – Direction deposition (low energy ions) – Chemical-assisted deposition 18 FIB – etching/deposition Nano Factory Achieved by Focused Ion Beam Toshiaki Fujii, and Takashi Kaito, Microsc Microanal 11(Suppl 2), 2005 - See more at: http://glia.ca/meanderings-wordpress/focus#sthash.06BIxsK8.dpuf 19 FIB - Deposition • Deposition of Pt on Al substrate to form micrograting for measuring material deformation 20 Soft Lithography • Alternative to photolithography • Cheaper / more flexible • Printing of Self-Assembled Monolayers (SAMs) • Molding of liquid precursors Techniques: • Microcontact printing • Nanoimprint 21 Microcontact Printing • “Stamp” made – Pour liquid polymer into a mold to make a “stamp” – Mold often made by photolithography • “Ink” the stamp – Dip into solution so SAM formed on surface of stamp • Stamp the substrate – Place the inked stamp on a substrate – SAM transferred to substrate in specific pattern 22 Microcontact Printing Voskuhl, J., Wendeln, C., Versluis, F., Fritz, E.-C., Roling, O., Zope, H., Schulz, C., Rinnen, S., Arlinghaus, H. F., Ravoo, B. J. and Kros, A. (2012), Immobilization of Liposomes and Vesicles on Patterned Surfaces by a Peptide Coiled-Coil Binding Motif . Angew. Chem. Int. Ed., 51: 12616–12620. doi: 10.1002/anie.201204836 23 Nanoimprint 1. Make template 2. Coat substrate with polymer 3. Press stamp into polymer at high temperature; polymer deforms 4. Cool polymer and pull stamp away 5. Polymer can be then be etched or used as is 24 D.R. Hines et al., Appl. Phys. Lett. 86 (16), 163101 (2005). Nanomanipulation and Nanolithography Based on Scanning Probe Microscopy (SPM) techniques - can be used for molecular manipulation Types of Scanning Probe Microscopy (SPM) • Scanning Tunneling Microscopy (STM) – Electrically conducting materials • Atomic Force Microscopy (AFM) – Dielectric (insulating) materials 25 • STM with Tungsten tip • Placed Xenon atoms on surface • UHV and low temperature – Clean environment and surface – Absence of thermal diffusion on surface Nanomanipulation D.M. Eigler and E.K. Schweizer, Nature 344, 524 (1990). 26 The World’s Smallest Movie 27 Nanomanipulation with AFM • Perpendicular Processes: atoms lifted, then dropped • Parallel Processes: atoms dragged along surface • Pushing • Pulling • Sliding C. Baur, et al., Nanotechnology 9, 360 (1998). 28 Advantages • Nanoscale control in three dimensions, necessary for atomic manipulation • Manipulation and characterization Disadvantages • Small scanning area • Slow scanning • Tips must be high quality and consistent • Surface must be flat and smooth • UHV and low temperatures SPM Nanofabrication 29 • Works under ambient conditions • Scan tip across substrate, atoms or molecules move from AFM tip to substrate Dip-Pen Nanolithography (DPN) C. Mirkin, Northwestern Univ. 30 Polymer Pen Lithography • DPN + µCP 11 million pen array http://cen.acs.org/articles/87/i12/BoronDreams.html Science 19 September 2008:vol. 321 no. 5896 1658-1660 31 Summary • Photolithography – Reaching size limits (diffraction, etc.) • Soft Lithography – Relatively new – Fabrication of nanostructrures and nanodevices • SPM-based techniques – Relatively new – Promise for using atoms and molecules as building blocks 32