Section 09-Dristributed Utility Shuttle Technology

advertisement

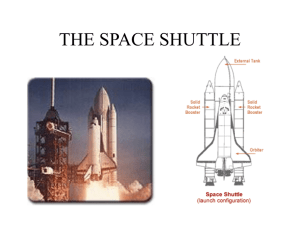

Current Need Aging space shuttle fleet’s retirement is imminent If the ISS is going to continue operation there needs to be a replacement to get humans to orbit fast and reliably Why waste all engineering and infrastructure currently in place for shuttle? With a burgeoning worldwide space industry a global network of advanced air and space ports will be needed to manage the increased number of flights DUST Merge past, existing, and future technologies to revamp the space shuttle program in 3 step process: Combine American Space Shuttle, Russian Buran, and current technologies Create multiple versions of the shuttle, i.e. passenger travel, scientific missions, cargo transport etc. Distribute manufacturing and communications around the world Allow space faring and developing nations to work together in a similar fashion as the ISS Incorporate private industry for cargo transport and pointto-point earth travel Not just a vehicle but a globalized architecture Space Shuttle Program Reusable high payload capacity vehicle Large, complex support system already in place Expensive program that requires large long term investment Total thrust of about 12,500 kN Shuttle Myths Capsules are cheaper than STS Currently capsules carry 3-4 crew STS capable of 8 up to 12 perhaps Shuttle Myths Shuttle concept and architecture is unsafe Although ET and SRBs have failed in the past, the orbiter is the safest vehicles Smooth ride and re-entry that capsules can never offer STS evolution is expensive - Is it cheaper to start from clean slate and look for new paradigms or cheaper to insert new and maturing technologies into STS architecture Shuttle is very expensive compared to capsules With a higher payload capacity is it really more expensive when compared to these smaller vehicles Soviet Buran Program Single liquid booster stage Much smoother launch than the SRB provide on the space shuttle Most powerful rocket ever created, 29,000 to 32,000 kN Orbiter does not boost itself into orbit Booster stage burns up on reentry Only flown once program cancelled shortly after Past, Current, and Latest Technologies SSME is one of the best cryo systems ever made so why change it? Utilize the Buran liquid booster system Russian Energia (heavy lifting system) can provide smoother flight and more control than SRBs Capable of lifting 100 metric tons into orbit The flight testing and design work has already been completed, no need to create a new vehicle and spend time and money doing this again Update the foam insulation on the space shuttle with latest technology to prevent damage that has occurred in the past Variations Private Industry Corporations such as SpaceX and Virgin Galactic Used for point-to-point suborbital travel and earth to LEO (ISS) cargo transportation How to Build It?: Global Manufacturing Case Study: Boeing 787 Global Supply Chain Instead of building the complete aircraft from the ground up in the traditional manner, final assembly would employ just 800 to 1,200 people to join completed subassemblies and to integrate systems Boeing assigned its global subcontractors to do more assembly themselves and deliver completed subassemblies to Boeing for final assembly Intended to result in a leaner and simpler assembly line and lower inventory Pre-installed systems reducing final assembly time by threequarters to three days. Unforeseen Problems Intended to shorten the production process, 787 subcontractors initially had difficulty completing the extra work They could not procure the needed parts, perform the subassembly on schedule, or both, leaving remaining assembly work for Boeing to complete as "traveled work” From the beginning of 2007 to 2008 the program was delayed 4 times Global Network Network of worldwide spaceports built in countries throughout the world Will start in the more developed world and spread to countries that are part of the manufacturing network Private corporations will be brought in main for cargo transport and point-to-point earth transport Updated Global Tracking and Data Relay Satellite (TDRS) First put into service in 1983 Goal to increase the amount of time that spacecraft were in communication with the ground and improve the amount of data that could be transferred3 Third generation network beginning to come online within the next 5 years Global FAA needed Way Forward Similar to ISS develop global coalition to build and develop new shuttle program Distribute the work throughout the world Perfect the shortcomings of the Boeing distributed manufacturing method Allow developing countries to contribute heavily to the network and future ISS operations Questions References Boeing Unveils 787 Final Assembly Factory Flow." Boeing. December 6, 2006. "Boeing's Big Dream", Fortune Magazine, May 5, 2008, p. 182. (online version). http://tdrs.gsfc.nasa.gov/