Magnolia Platform

advertisement

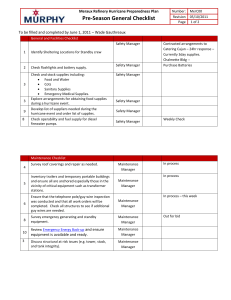

Hurricane Response, Preparedness, and Lessons Learned Lake Charles Refinery Excel Paralubes Lake Charles Coke Terminal Lake Charles Pipeline Co. Alliance Refinery Clifton Ridge Marine Terminal Pecan Grove Marine Terminal High Island Gulf Coast Lubes Plant Platforms Green Canyon Platforms Magnolia Platform Corporate Crisis Management Support Team Staff Chart Updated 07/07/2005 (rev. 22) CMST Manager Crisis Advisor See Specific CMST BU Org Chart Corporate HSE Call Center Coordinators Chief of Staff Corporate HSE Positions staffed by the affected business Positions staffed by the CMST (Core CMST) Deputy CMST Manager Positions staffed by Functional Support Plan Resources Human Resource Function Lead Legal Function Lead See Specific CMST BU Org Chart See Specific CMST BU Org Chart Government Affairs Function Lead Medical Function Lead Planning Lead Operations Lead Situation Unit DE&O Function Lead Support Resources Business Interruption Lead Information Function Lead Logistics Lead Safety Function Lead Finance Function Lead See Specific CMST BU Org Chart See Specific CMST BU Org Chart Documentation Unit Security Function Lead Resource Unit Environmental Function Lead Information Systems Function Lead Communications Unit Additional support personnel and services are provided through the IS FSP Procurement Function Lead Aviation Function Lead Travel Function Lead Risk Management/Corp. Insurance Function Lead Claims Function Lead Lessons Learned • Opportunities for improvement broken down and summarized in 4 categories – Process Improvement – Information Management and Direction – Organization – Design and Integration – Infrastructure – Facilities and Technology – Training and Skills - Functional Capability Lessons Learned • Process Improvements – Use phased ramp-up of crisis management team based on situation – Develop and follow robust documentation process – Develop and use an action item tracking process – Assure situation briefing are given to all involved people – Stay in process Lessons Learned • Organization – Integrate all levels of response into a single organization (One Plan) – Train personnel on different roles and responsibilities – Drill the emergency response organization Lessons Learned • Infrastructure – Identify remote operations centers in advance of event – Improve availability of emergency response plans in EOC – Develop and communicate response objectives to entire team quickly – Utilize networked software to provide equal access to all information by all team members – Develop and implement de-mob checklists for emergency response teams Lessons Learned • Training and Skills – Provide training on software used to capture and manage information – Train business units on setting objectives and directing the team – Keep training content current and provide in a timely manner. Upstream Upstream Actions • • • • Hurricane Preparation and Evacuation procedures updated based on hurricane experience Performance study conducted on Gulf of Mexico Magnolia Platform Equipment modification completed on Magnolia Platform Each new Louisiana inland water platform design is now evaluated from a risk/benefit basis to build at a height equal to the 100 year flood level Magnolia Platform • The Magnolia field was • discovered in 1999 (1st production 2004) and is located 165 miles south of the Louisiana coastline in Garden Banks blocks 783 and 784. Magnolia is located in almost 4,700 feet of water. Magnolia had no major equipment failures – and that was in spite of Hurricane Rita’s eye wall passing within 25 miles of the facility. Equipment Changes on Magnolia Platform • Gulf of Mexico platforms • have installed storm latches to all doors to prevent doors being blown open resulting in water/wind damage to the interior. Also installed wind diffusers for the Auxiliary Generators to prevent overheating & shutdowns caused by hurricane force winds. Magnolia Platform Performance Study • • • Study conducted by an external engineering group (Houston Offshore Engineering) Study assumed Magnolia Platform exposed to a direct hit by a “Rita” type hurricane Conclusion of the study was that even though environmental conditions were significantly higher than design criteria • Platform would withstand storm without loss of integrity – No over tensions of tendons – No periods of tendons going slack • Highest wave crest would be one foot below bottom of deck Downstream ConocoPhillips Alliance Refinery Hurricane Katrina ConocoPhillips Alliance Refinery Hurricane Katrina ConocoPhillips Lake Charles Refinery Hurricane Rita ConocoPhillips Lake Charles Refinery Hurricane Rita Downstream Actions • • • • • • Conduct annual hurricane plan drills before season commences Conduct audits during season to verify level of preparedness Setup dedicated employee storm communication hotline Load hurricane plans in Incident Action Plan software (same as used by IMAT) Identify, dedicate on site response equipment for use at any of the Gulf Coast facilities Remove critical electric motors prior to storm Gulf Coast Recovery Equipment Plan • Gulf Coast recovery equipment identified at the • • • • • end of 1st quarter Identified recovery equipment is procured in 2nd quarter Equipment will be housed and maintained at Sweeny Refinery Transportation is charged with moving equipment • Permits to allow transport of equipment will be filed prior to storm Proper equipment to unload portable equipment at site will be identified One hurricane plan coordinator will be designated for Gulf Coast region Refinery Specific Actions • Lake Charles Refinery • Sweeny Refinery • Upgrade overhead electrical system in tank farm area (5 year plan) • Evaluating options to reduce water intrusion in selected sub stations. • Manage hurricane response equipment for the Gulf Coast area • Pursuing agreements with local maintenance contractor to provide housing repair assistance Refinery Specific Actions • Alliance Refinery • Operations Control and Maintenance Field Office buildings upgraded to withstand 200 MPH winds • Mississippi River levee evaluated – Corp of Engineers allow a levee height of 16 feet and will not permit any height increases – Height of levee at 2 points of washout during Katrina were 14 feet in height due to pipe way crossing – Discussions underway with the Corp to allow increase in height to 16 feet • Project approved to increase water pump off capability • All future motor control centers and instrument buildings will be elevated to protect from rising water • Instrument upgrade project is open architecture which allows easy replacement in the event of damage • Decision and Risk Analysis currently underway to develop best protection scenario for the refinery