Journal of industrial microbiology & biotechnology, 39

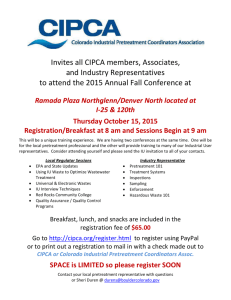

advertisement