Preparation of Papers in Two

advertisement

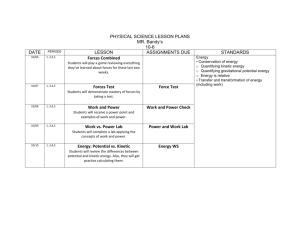

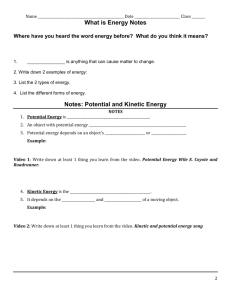

Mechanical Engineering 2165 FLYWHEEL BASED KINETIC ENERGY RECOVERY SYSTEM FOR AUTOS Andrew Kearns (AJK95@pitt.edu), RJ Liu (YUL89@pitt.edu) Abstract—Because of the energy crisis, fuel efficiency is becoming more and more important in the auto industry. Therefore, automotive engineers are exploring new approaches to achieve the goal of saving energy. In this paper, we will carefully examine one of the approaches— flywheel based kinetic energy recovery system, or KERS, which stores kinetic energy on a flywheel as a car breaks and releases that energy while accelerating [7]. KERS improves fuel economy by storing large amounts of energy in a flywheel, and it is an important technology because it can help reduce the damage that humans do to the environment by burning fossil fuels. This paper will discuss the kinetic energy recovery system and the way it functions in detail. It will discuss the mechanics of the system as well as the physics behind it. In addition we will also discuss the ethics relating to this technology. Through this paper we will show the readers a different approach to dealing with the energy crisis. Not only can we find new ways to make energy, we can efficiently reuse the energy that a system already has. for the cars due to better fuel efficiency [4]. In this paper, we will examine the flywheel based kinetic energy recovery system and explain why it is the fuel efficiency technology of the future. THE PHYSICS BEHIND KERS Flywheel kinetic energy recovery system is complicated, but it is based on some very basic physics. The mechanical kinetic energy recovery system stores kinetic energy, the energy of motion, in a flywheel. This can be explained by the law of conservation of energy, which states that the energy of a system cannot be created or destroyed. Energy is transferred from one form to another. For example, the energy of a pendulum changes from potential energy to kinetic energy as it swings from its raised position to the lowest point of its motion, then the kinetic energy is converted back to potential energy as it swings back up to its maximum height. Eventually the pendulum will stop swinging because the energy of the system is lost to air resistance. Friction between air and the pendulum eventually converts the kinetic and potential energy of the system into heat energy. This is the concept that KERS uses. Kinetic energy is stored in the rotational motion of the flywheel and then the trasmission transfers the energy so it can be used again to accelerate the vehicle. The kinetic energy of a spinning object is equal to the half the product of the moment of inertia and the square of its angular velocity. In plain english what that means is the faster an object spins, the more kinetic energy it has. The moment of inertia is different for all objects. It depends on the distribution of mass in an object. For a flywheel, the moment of inertia depends on its radius and mass. In other words, the larger and heavier the flywheel is, the greater its moment of inertia is. Because of this, large and dense flywheels are able to store large amounts of kinetic energy. Kinetic energy of rotating objects also translates to linear velocity, the forward motion of the car. The bottom line is if a flywheel is capable of storing large amounts of kinetic energy, it will translate to a greater linear velocity for the automobile. The second law of thermodynamics along with conservation of energy is the reason why mechanical KERS is superior to electrical KERS. The second law of thermodynamics states that imbalances of heat energy will eventually balance out and reach equilibrium. Because of this, no transfer of energy is one hundred percent efficient. Energy is always lost to heat. Electrical kinetic energy recovery systems transfer kinetic energy to chemical energy, then the chemical energy is changed to electrical energy and stored for later use. With each transfer of energy, some of Key Words— flywheel, transmission, kinetic energy, continuously variable transmission, kinetic energy recovery system, moment of inertia, transmission, torque, rotational velocity INTRODUCING THE MECHANICAL SOLUTION In this day and age, the whole car industry is facing a great conflict between continuous development and enveronmental issues. In recent years especially, there has been a push for more fuel efficient vehicles. In part, this is because of increasing gas prices. More importantly, negative effects on the environment have caused this trend. Engineers are taking fuel efficiency to entirely new levels by developing new ways to get the most out of the fuel we use to power our automobiles. Cars have become lighter, more aerodynamic, and more efficient. Hybrid technology brings electricity into the mix as a more environmentally friendly source of energy. Hybrid technology introduces an interesting way to make vehicles more efficient and environmentally friendly. By combining traditional gas powered engines with electrical motors, they reduce mmisions and fuel consumption. One fairly new system engineers have designed is the flywheel based kinetic energy recovery system, or KERS. It is a complex system, but the physics behind it are simple to understand. This kinetic energy recovery system stores energy as a vehicle breaks, stores it, and recycles it as the vehicle accelerates again [7]. The kinetic energy recovery system was first designed for formula one racing cars, and it is now a mandatory system University of Pittsburgh Swanson School of Engineering March 1, 2012 1 Andrew Kearns RJ Liu the energy is lost to heat. Mechanical KERS simply transfers kinetic energy from one place to another. The simplicity of this aproach minimizes the loss of energy in the system. This brings up an interesting point. Flywheel kinetic energy recovery system transfers energy, so some energy is lost. This is not an issue though, because KERS stores energy that ordinary cars would waste anyway. amounts of heat. The solution the Flybrid engineers came up with is to enclose the flywheel in a vacuum [6]. KERS AS A WHOLE The whole concept of kinetic energy recovery system, KERS, was introduced a while ago. However, formula one racing brought the concept into automotive industry in 2006. This offered the auto industry a brand new way to cope with energy crisis, and with a rapid pace. This KERS technology is about contributing to our society. The flywheel system is the most direct mechanical method to store and recycle energy. The principle for this system is simple, a flywheel connected by a continuously variable transmission, or CVT, to the drivetrain. The system stores energy when the transmission moves to the ratio that speeds up the flywheel. This energy is released when the transmission moves toward the ratio that slows down the flywheel. Since this system mainly composed by two parts, this paper will explain these two parts, the flywheel and the clutched flywheel transmission, separately. FIGURE 2 FLYWHEEL COMPUTER GENERATED MODEL OF A FLYWHEEL DESIGNED BY FLYBRID [6]. For a functional flywheel system, there are three critical aspects, the flywheel, the seal, and the safty. The flywheel is the main energy storage unit. According to sae.org, Bosch Engineering has developed a flywheel system that is capable of storing amounts of energy up to 750kJ [1]. This amount of energy is equivalent to that of a one ton object traveling at 90 miles per hour as (1) shows. That resolves the friction issues but raised the problem of getting power in and out without air leaking in. This leads us to our next topic. THE SEAL In order to incase the flywheel in a vacuum chamber, the seal is essential. The seal is the company’s own patentable design and Hilton is unwilling to reveal the details of their sealing technology. Therefore, based on the traditional sealing method, we came up with an idea of how it may work. Many high speed turbo chargers use fluid bearings that consist of a layer of oil that is constantly pumped around the turbine shaft. Our solution is very similar; we would use a pump to constantly circulate oil to the area where the surfaces would be making contact. Not only does this method seal the machine, but it also allows for minimal friction and cools the shaft as it spins to prevent it from overheating. 750kJ = 750000J 1 ton = 907.18474 kg KE = (1/2)mv 2 v = √(2KE/m) v = √((2*750000J)/907.18474 kg) v = 40.6628 m/s 40.6628 m/s = 90.9601 mph FIGURE 1 SAMPLE CALCULATION SHOWING WHAT KIND OF ENERGY KERS IS CAPABLE OF STORING To achieve the maximum energy storage the speed of the flywheel has to reach 64,500rmp. As the result, the flywheel is made from carbon filament wrapped around a steel hub. The reason engineers chose this particular material is that the tensile strength of the carbon will effectively prevents the flywheel from shattering under the great force of high rotational speed. However, that in turn creates windage losses that greatly reduce the power and produce enormous THE SAFETY Obviously, the company knows that one major injury or fatality associated with the system would spell the end of the technology and the company, so safety had been a top priority throughout the project. The company made tremendous tests to ensure that the whole system was 2 Andrew Kearns RJ Liu reliable. The enigneers confined the damage to the flywheel and containment rings, while the other parts will remain undamaged and able to be re-used. Moreover, they also attached accelerometers to look for tell-tale signs of impending failure [6]. flywheel kinetic energy recovery system. This would undoubtedly have a positive impact on the environment. Burning significantly less fossil fuels would means less pollution. This would make the air we breathe healthier and it could slow the effects of global warming. The effects on the environment are not the only ethical concern when it comes to KERS. Safety is also a very important point. The bottom line is if a technology is not safe, it simply cannot be used. Despite the high rotational speed of the flywheel, the kinetic energy recovery system has been proven to be completely safe [3]. The engineers who designed the flywheel were able to design the kinetic energy recovery system in a way that does not put people at risk. Besides, formula 1 race cars have safely used flywheel kinetic energy recovery systems, and production cars do not produce as much energy as race cars [7]. If the flywheel kinetic energy recovery system has been proven to be safe for use in race cars, it will not harm people who are just driving their car down the street to the supermarket. TRANSMISSION CFT is regarded as the first true second generation transmission system. It replaced the continuously variable transmission, and it reduced size, weight and cost for mass production in the future. Weighted at less than 18kg, its plan view section can fit on an 8”×11” piece of paper [6]. As is shown in (3), CFT is small and versatile enough that it can be placed in multiple locations, making it very easy to install. ELECTRIC VERSES MECHANICAL Thanks to the cars such as Toyota Prius, Honda Insight, or Chevrolet Volt, when speaking of kinetic energy recovery system, people usually think about vehicles powered by an electric motor. There is no denying that electric hybrid vehicles have proved to have great efficiency and therefore less impact on the environment. However, electric-gasoline is not the ultimate solution for a hybrid car in comparison with the flywheel based kinetic energy recovery system. First of all, electric hybrid cars are expensive. It is obvious that electric cars are much more expensive than normal cars, because the material used for electrical car has a high cost due to the rareness of material itself. Besides, lithium ion polymer batteries only last 3 years before they die, so battery replacement will be a major cost for a hybrid car owner. Flywheel kinetic energy recovery systems are made out of traditional materials. Therefore they maintain a lower cost and greater reliability. Secondly, the whole concept of environmental friendly for an electric hybrid car is kind of misleading. Since an electric-gasoline car is usually made by material from all over the world, the carbon consumption to make an electric hybrid is way more than that of a normal car. Also, used batteries can cause big issues with the environment. In comparison with electrical hybrid, the flywheel based kinetic energy recovery system costs less to make and it is recyclable, for it is made entirely of metal. Finally, the most critical reason why flywheel KERS is superior to the electrical motor is that the flywheel is much more efficient. Flybridsystems.com states that cars with flywheel kinetic energy recovery systems have “a better power to weight ratio than existing automotive hybrid technologies [6].” The mechanical hybrid approach is superior to the electrical hybrids. This is due to the second law of thermodynamics, transforming energy from one form to another inevitably introduces a loss of energy. For battery FIGURE 3 DIAGRAM SHOWING THE DIFFERENT LOCATIONS CTF CAN BE PLACED [6] The CFT transmission uses a series of separated gears and high-speed clutches that perform a controlled slip to transmit the drive. Basically, there are three gears in the CFT KERS, and all of them can be connected to the main vehicle transmission, therefore, providing a larger number of ratios between the flywheel and the wheels of the vehicle [6]. (Number of total gear ratios = 3 CFT KERS * number of car gearbox speeds). To achieve the highest efficiency and accuracy possible, the gear-changing is controlled by software which selects the most appropriate gear. Then it partially engages the high-speed clutch associated with that gear [6]. Furthermore, by applying hydraulic pressure to close or open the clutches, the whole system will run smoothly without torque interruption. ETHICS For every single project engineers work on, functionality is key, but ethics are just as important to professional engineers. Engineers cannot put a solution to a problem into effect if it is not ethical. The flywheel based kinetic energy recovery system is ethical. This is a result of its efficiency and its safety. Because the kinetic energy recovery system increases fuel efficiency, our society would burn less fossil fuel if it was used in all vehicles. Think of how much fuel could be conserved if every automobile on the road used 3 Andrew Kearns RJ Liu based hybrid drive systems, there are four energy-sapping transformations: 1. Kinetic energy is transformed into electrical energy in a motor/generator. 2. Electrical energy is transformed into chemical energy as the battery charges up. 3. The battery discharges, transforming chemical into electrical energy. 4. Finally, the electrical energy passed into the motor/generator acting as a motor and is transformed once more into kinetic energy. The four energy transformations greatly reduce the level of efficiency. For instance, let us consider a motor that makes 75% under the peak load, both on the way in and out. Also consider a battery that makes 70% both on the way in and out. The resulting overall efficiency will be less than 30%. Unlike the electrical approach, the flywheel based approach will avoid most of energy loss by keeping the energy in the same form as energy is stored and released. Simplicity is superior when it comes to transferring energy. So from what we have discussed above, we can draw a conclusion that the flywheel based will be the trend of future design, because it is easy, economical, and efficient. TECHNOLOGY OF THE FUTURE Kinetic energy recovery system can make every car more efficient and powerful. Because of this, it can also reduce the negative impact on the environment due to burning fossil fuels. The flywheel kinetic energy recovery system stores kinetic energy in a flywheel as a car decelerates. Then as the car accelerates, the kinetic energy stored in the flywheel is transferred back to the forward motion of the car as a boost of acceleration. Due to the simplicity of energy transfer in the mechanical system, it is superior to the electrical kinetic energy recovery system. Mechanical hybrids are more powerful, more efficient, and cheaper than electrical hybrids. In the future, automobiles will be much more fuel efficient than the cars of today. What started out as a technology for formula 1 race cars will be a standard component of automobiles. Flywheel kinetic energy recovery system technology is definitely practical because multiple car companies are looking into using the system in the production cars that consumers drive. Volvo officially announced that they intend to develop and produce a vehicle that uses the flywheel based kinetic energy recovery system. As technology improves, KERS will become even more efficient and affordable. It would be ignorant to think that the flywheel kinetic energy recovery system or a similar technology will not contribute to their superior efficiency. KERS TECHNOLOGY IN THE REAL WORLD Although cars with flywheel based kinetic energy recovery system are more expensive than cars without flywheel kinetic energy recovery system, the cars that have the system have more power and have better fuel efficiency. According to thegreencarwebsite.co, “the system could reduce fuel consumption by as much as 20 percent and give a fourcylinder engine acceleration like a six-cylinder unit [8].” This means that cars that have flywheel kinetic energy recovery system burn less fuel and have more power than cars that do not have the system. Another source states that, “According to Derek Crabb, vice president of Volvo's powertrain engineering division, Flywheel KERS has the potential to reduce fuel consumption by up to 20 percent [5].” This shows that well known car companies are looking into using flywheel kinetic energy recovery systems in their production cars. It also confirms the efficiency of the system. “Flybrid Systems have been working with a number of OEM car makes including Jaguar Cars to develop flywheel hybrid systems for road cars [6].” Road cars with flywheel kinetic energy recovery systems are definitely going to exist within the next few years. Consumers would not mind paying extra for a car with flywheel kinetic energy recovery system because it will have a good amount of power and it will save them money on fuel in the long run. By paying a higher fixed price while purchasing a vehicle, consumers will be able to save enough money on fuel to make it worthwhile. This will be especially true if gas prices continue to increase. REFERENCES [1] Birch, Stuart. "Motorsports/Performance - Automotive Engineering International Online." SAE International. 8 Dec. 2008. Web. 11 Jan. 2012. <http://www.sae.org/mags/aei/5139>. [2] Boretti, Alberto. "Comparison of Fuel Economies of High Efficiency Diesel and Hydrogen Engines Powering a Compact Car with a Flywheel Based Kinetic Energy Recovery Systems." International Journal of Hydrogen Energy 35.16 (2010): 8417-424. Print. [3] Collantine, Keith Collantine. "KERS Explained: How a Mechanical Kinetic Energy Recovery System Works." F1 Fanatic – The Formula 1 Blog. 11 Jan. 2009. Web. 11 Jan. 2012 [online]. <http://www.f1fanatic.co.uk/2009/01/11/kers-explained-how-a-mechanicalkinetic-energy-recovery-system-works/>. [4] Evans, Paul. "Formula One KERS Explained." Gizmag | New and Emerging Technology News. Web. 11 Jan. 2012 [online]. <http://www.gizmag.com/formula-one-kers/11324/>. [5] Feed, By Eric Loveday RSS. "Volvo to Test Fuel-saving Flywheel KERS System [w/video]."AutoblogGreen -- We Obsessively Cover the Green Scene. Web. 11 Jan. 2012 [online]. <http://www.green.autoblog.com/2011/06/02/volvo-to-test-fuel-savingflywheel-kers-system-w-video/>. [6] Home - Flybrid Systems. Web. 25 Jan. 2012 [online]. <http://www.flybridsystems.com/index.html>. [7]"Kinetic Energy Recovery System | KERS | Formula One (F1) KERS | How It Works | Mechanical Engineering." Mechanical Engineering Blog. Web. 11 Jan. 2012 [online]. <http://www.mechanicalengineeringblog.com/1636-kinetic-energyrecovery-system-kers-formula-one-f1-kers-how-it-works/>. [8] Lucas, Paul. "Volvo to Develop Kinetic Energy Recovery System." Green Cars: Cars with CO2 Emissions under 150g/km plus News, Information, Articles and Press Releases. 27 May 2011. Web. 29 Feb. 2012. <http://www.thegreencarwebsite.co.uk/blog/index.php/2011/05/27/volvoto-develop-kinetic-energy-recovery-system/>. [9] Prodromidis, George N., and Frank A. Coutelieris. "Simulations of Economical and Technical Feasibility of Battery and Flywheel Hybrid 4 Andrew Kearns RJ Liu Energy Storage Systems in Autonomous Projects." Renewable Energy 39.1 (2012): 149-53. Print. ACKNOWLEDGEMENTS We would like to thank Scott and Pramod Jacob, our chair and co-chair for giving us guidance and advice on this paper. 5