Will Linear Elasticity Last Forever

advertisement

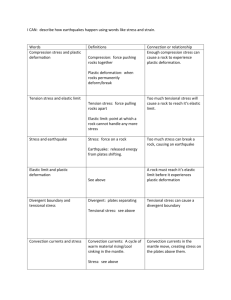

Will Linear Elasticity Last Forever (Credit for many illustrations is given to McGraw Hill publishers and an array of internet search results) Takeititto tothe the Limit Limit OrOr Take Parallel Reading Chapter 2 Section 2.8 A Real Life Case I wonder if this just goes on forever? σ E ε An engineer designed a tunnel Supported on both sides by Pillars of rock. The engineer put Young’s Modulus For the rock into the computer And without paying much attention Told the computer the linear Stress strain relationship went on Forever. The computer confirmed that the Tunnel would be stable even though The weight of 2,400 ft of rock above Was large for the support pillar size The Pillars Suddenly Exploded in a Chain Reaction wiping out a mile of tunnels The good news? The people working in the tunnel never knew what hit them The Moral of the Story • Linear Elasticity does not go on forever – (of course we knew that – dip stick the computer jocky just got careless with his program inputs) So What Does Happen? • That depends on the material One Possibility Of Course We Hope We Have the Sense to Back-off in Time Loading σ Unloading follows the same path down Called Elastic Behavior ε If We Push Beyond our Elastic Limit we begin to create permanent Deformations Plastic Behavior (we noted our brittle material tried A little plastic behavior but then Failed) Some Materials Have a Bit More Plastic Range These are called ductile materials They give us a lot of plastic Deformation before they Finally break A Few Terms A materials shows a nice linear stress strain relationship. Eventually that linear Relationship starts to slip just a little and the elastic region ends. For most engineering designs you will confine yourself to the elastic region. Closely Related Terms For most materials the Elastic region starts to taper Off a little Where the nice straight line Starts to taper is called the Proportional Limit (Hooke’s Law starts to slip A little above this point) Most materials will still rebound back without deformation for a short while after The line slope tips a little. When plastic deformations start to set-in we call that The Yield point. Some materials don’t have a well defined plastic deformation yield point Offset Yield Point or Proof Stress Start at 0.2% strain – go up at the Young’s Modulus slope – when you hit the curve you Call it the Offset Yield Point and use that as The Yield Point. More Terms Even as the material goes Plastic it may still take some Additional stress. The highest stress that the Material will take is called The “Ultimate Tensile Strength” Of Course Ductile can Have Twists Some materials suddenly yield as they go plastic We can talk about Yield points or limits (except of course not All materials have Them) And the develop a little more resistance as they Stretch. What is that Weird Dip at the End? The Specimen Starts Necking Lets Get that Right The Specimen Starts Necking As the specimen thins There is less area Even though our Stress strain curve Assumed the area Stayed the same. If You Consider the Change In Area The line keeps on going up to the breakpoint. The dip is an artifact of our constant area assumption So if We Behave Well and Design in the Elastic Range are We OK? Maybe not. It turns out that repeated Loading cycles make things Fail at lower stress levels. It was called metal fatigue because when it was first discovered people believed The metal “got tired” The drop in failure point with repeat loadings can be seen in test results Metal Fatigue Can actually lower the failure Point. Aloha Airlines Flight 243 A regional carrier using mostly Boeing 737’s on short runs with large numbers of Landing and take-off cycles. The Problem of Metal Fatigue Side split in mid air at 24,000 feet Sucking a flight attendant out. The top of the plane Ripped off in the sky Somehow the Pilots Landed the Thing How is Testing Done A polished smooth test specimen is prepared It is put in a machine that puts a bending load On the specimen and then rotates it Rapidly. The specimen undergoes repeat Cycles of tension and compression As it rotates. The Point at Which Failure Occurs After 10,000,000 cycles is called the Endurance Limit For steel with an ultimate tensile strength Of under 160,000 psi it is about 50% Of the ultimate strength. For very high strength materials it is Usually less. Interesting Observation If my test specimen is nicked or Corroded it has a lower endurance Limit. (If people keep re-polishing the test Specimen the will take longer to fail) Cracks Propagate from Points of Weakness Some of you have seen this when a Rock gets flipped up and hits your Windshield. The stress at the end of a crack is incredible (using math only an M.E. could love) Some Fractures are Obvious Others are Not Defects can be at mineral grain boundaries Or even at the atomic level Once cracks start to propagate they are like a cancer – and will keep on growing (which is why re-polishing test specimen surfaces helped) Keeping Below Endurance Limits For steel you can see that after Some point the failing stress levels Off. If you stay below this point We say the material has infinite life. Then there are materials like Aluminum that don’t seem to have A stress level that will provide Infinite life. Not All Materials Are Perfectly Polished There are class specific procedures For adapting endurance limits to Specific cases. Interesting consideration – Ford is looking to reduce vehicle weight by replacing Steel in their vehicles with aluminum. Could Ford get into some design issues with which their experience in building Steel vehicles has not prepared them? Unique Materials Properties One of the Reasons for in Depth Classes • Classes in Steel Structures • Classes in Concrete Structures • Classes in Pre-Stressed and Cast Concrete • Classes in Soil Mechanics • Classes in Rock Mechanics Would Anyone Ever Try to Operate Outside the Elastic Range • For most types of things we try to avoid the plastic ranges • Plastic Ranges can be important for things like shaping steel fenders out of sheet metal – Lots of shaped panels are made of steel – not many from aluminum – any idea why?