What Can We Expect

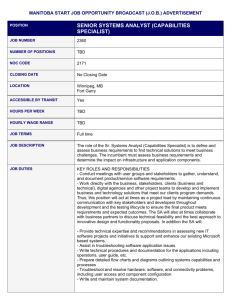

advertisement

Harvest 2015: What Can We Expect Charles R. Hurburgh Agricultural and Biosystems Engineering September 15, 2015 page 1 page 2 page 3 page 4 page 5 page 6 Production (2015 as of 9/01/2015) Yield (bu/a) 2014 Billion bu_____ 2015 2014 2015 14.22 13.58 2.37 2.41 Corn USA Iowa 171.0 167.5 178 181 Soybeans USA Iowa 47.8 47.1 3.97 3.94 51.5 53.0 0.51 0.53 page 7 Stocks (June 1) (Billion Bushels) 2014 2015 USA 3.85 4.45 Iowa 0.73 0.88 (~55% farm) 0.41 0.094 0.63 0.126 (~40% farm) Corn Soybeans USA Iowa page 8 Storage Space (all grains)(billion bushels) On Farm Off Farm_____ 2014 2015 2014 2015 USA 13.0 13.2 10.4 10.5 Iowa 2.1 2.1 1.4 1.4 page 9 Storage vs Crop, Iowa 2014 2015 Production On hand 2.95 0.82 ------3.77 2.94 (corn and soybeans) 1.01 (high – June) ------3.95 (billion bushels) Storage 3.50 3.50 Balance 0.27 0.45 Grain likely outside for a short time Usage = 200 – 240 MM Bu/month page 10 Corn Quality –Scenarios for 2015 • Warm and Wet – Large kernels, medium/low test weight, wet corn – Fair to poor storage properties – Maybe vomitoxin? • Cool and Wet – Large kernels, medium/low test weight, 20%+MC – Poor storage properties – Vomitoxin more likely • Warm and Dry?!: – Large kernels, medium/low test weight Corn Quality Trends - Example Year Yield bu/a 15%M 2009 2010 2011 2012 2013 2014 194.1 184.9 207.6 152.0 201.3 191.8 Test Weight Moisture Protein lb/bu % % as-is 15%M 15%M 54.0 57.6 58.7 60.1 57.0 55.0 25.6 14.3 16.8 16.5 19.8 20.3 7.6 6.7 7.2 8.2 6.9 6.6 Oil % 15%M Starch % 15%M Density gm/cc 15%M 3.6 3.5 3.6 3.4 3.5 3.6 61.1 61.6 61.2 60.6 61.3 61.5 1.244 1.255 1.271 1.287 1.254 1.250 Plots are usually ~ 2 lbs/bu heavier than field run, ~ 2 % pts drier 4 strip trial tests, 20-40 hybrids/location; Adair, Black Hawk, Bremer, Palo Alto counties in Iowa Soybean Quality –Scenarios for 2015 • Warm and Wet – Large beans, slow drying plants, good protein – Probably wetter beans/mixed beans at first. • Cool and Wet: – Large beans, wetter beans, composition? - Beans rewet to 14-15%, slow to dry after that. • Warm and Dry: – Large beans, high protein, normal moisture – Some later harvest fields. More harvest beans this year? Soybean Quality Trends - Example Year Yield bu/ac 13%M 2009 2010 2011 2012 2013 2014 58.7 58.7 65.9 52.5 53.6 60.3 Moisture Protein % % as-is 13%M 13.7 10.5 10.5 8.7 11.7 12.7 34.7 35.5 34.2 33.9 35.3 34.5 Oil % 13%M Fiber % 13%M Sum % 13%M 18.5 18.5 18.4 19.9 19.4 18.8 4.9 4.8 4.9 4.8 4.7 4.9 53.2 54.0 52.6 53.8 54.6 53.3 4 strip trial tests, 20-40 varieties/location Adair, Black Hawk, Bremer, Palo Alto counties in Iowa Harvest 2015 – preparations • Clean bins, aeration, dryers. • Scout/evaluate before harvest. – Mold (especially if storm damage) – Lodging (Lots of disease pressure) – Variability; breakage and FM if low TW. • Corn – soybean balance may be hard to estimate. – More soybeans will complicate end of harvest rush . page 15 Harvest Basics – Uniform drying and cooling (as best possible) – Adequate aeration (0.1 + cfm/bu) – Cooling cycle every 10-15 degree change – Get below 40F as fast as possible – Take out the center core of fines immediately – Regular inspection, temperature monitoring Temperature change is important (3 degrees) – Stay within temperature-moisture guidelines page 16 page 17 Corn Harvest 2015 - complexities • 2014 carryover corn in fair condition • Do not mix 2015 and 2014 in the same bin – Neither mixing nor layering will work • Rotate with 2015 crop or keep separate • First 2 weeks +/- : Submit daily composite samples. Can be out of dryer. – Check grading accuracy – Mycotoxin issue? – Check Test Weight increase page 18 Web-Based Training on Grain Storage • Dryeration: http://cai.iastate.edu/extension/dryeration/index.ht ml • Fan Performance: http://cai.iastate.edu/extension/fanperformance/ind ex.html • Grain Aeration: http://cai.iastate.edu/extension/grainaeration/index. html or go to www.iowagrain.org; link from there. page 19 And Now There is FSMA! • Animal Food to publish 9/17/2015 • Feed mills, ethanol plants, etc. must have: – CGMP – Hazard Analysis/Qualified Person – Verified Preventive Control Plan • Handling and Storage: Exempt - above only • Supplier verification required – you are a risk for users. • Lots of materials will be available. page 20 Creating a food safety/quality management system plan for a grain elevator. GEAPS Three hour Workshop Iowa State University Extension and Outreach Workshop Outline Brief Introduction: Dr. Charles Hurburgh Time The impact of the Food Safety Modernization Act on grain handling. Instructor: Dr. Angela Shaw 30 Creating Food Safety Plans - QMS Principles/structure related to FSMA - Writing objectives and procedures that can be documented, and validated Instructor(s): 30 Class exercise; designing a food safety hazard control procedure Instructor: Connie Hardy 30 --Break— 20 Cross Compliance: Other procedures-driven market or regulatory needs that can be met simultaneously. Occupational Safety plans Biosecurity/bioterror plans Environmental compliance plans. Pest control plans/sanitation Instructor: Dr. Gretchen Mosher 30 Economics: How to figure costs and benefits of quality management systems. Instructor: page 21 GEAPS 530 Quality Management Systems for Bulk Materials Handling Systems Created and Taught By: The Iowa Grain Quality Initiative Iowa State University Extension Charles R. Hurburgh, Jr., Professor Gretchen A. Mosher, Assistant Professor Howard E. Shepherd, Program Coordinator User’s Guide to ISO 22000 Food Safety Management System for the Grain Handling, Processing, Milling, and Baking Industries Compiled for the Food Safety, Quality, Regulatory (FSQR) Committee of AACC International by Charles Hurburgh, Jennifer Robinson, and Scott Jensen Sample text… User’s Guide to ISO 22000 Food Safety Management System for the Grain Handling, Processing, Milling, and Baking Industries Compiled for the Food Safety, Quality, Regulatory (FSQR) Committee of AACC International by Charles Hurburgh, Jennifer Robinson, and Scott Jensen Special callout sections… Food Safety Checklist Example Part 1: Food Safety Program Questions Yes Food Safety Program 1 A documented food safety program that incorporates Quality Management Program has been implemented 2 The operation has designated someone to implement and oversee the food safety program Name______________________________________ 3 All food safety documentation is located in one central location. Where:_____________________________________ 4 Records are kept for two years in an orderly manner. 5 A map of the facility and grounds is available. Download in MS Word @ No N/A Documents, filenames Chapter 1 INTRODUCTION TO FOOD SAFETY PREVENTIVE CONTROLS COURSE File: FSPCA Ch01 Intro 2014 11 06 1 2 3 TABLE OF CONTENTS 4 5 Hazard Analysis and Preventive Controls for Animal Foods Course Agenda viii 6 Food Safety Preventive Controls Alliance (FSPCA) – Animal Food Subcommittee (AFSC) ...............................................................................................................................iv Consider having someone take this Chapter 1: Introduction to Course ........................................................................................................... 1 training when it is offered (next 1-2 yrs.) 7 Chapter 2: Food Safety Plan Overview ....................................................................................................TBD 8 9 Chapter 3: Current Good Manufacturing Practices and Other Prerequisite Programs TBD ISU and others will have certified instructors. 10 Chapter 4: Biological Food Safety Hazards 11 Chapter 5: Chemical and Physical Food Safety Hazards .........................................................................TBD 12 Chapter 6: Preliminary Steps in Developing a Food Safety Plan ............................................................TBD 13 Chapter 7: Hazard Analysis and Preventive Controls Determination.....................................................TBD 14 Chapter 8: Process Preventive Controls ..................................................................................................TBD 15 Chapter 9: Sanitation Preventive Controls ..............................................................................................TBD 16 Chapter 10: Supplier Preventive Controls ...............................................................................................TBD 17 Chapter 11: Recall Plan ............................................................................................................................TBD 18 19 20 21 22 23 Chapter 12: Verification and Validation Procedures...............................................................................TBD Chapter 13: Recordkeeping Procedures ..................................................................................................TBD Chapter 14: Regulation Overview – cGMP and Hazard Analysis and RiskBased Preventive Controls for ........................................................................................................Animal Food Chapter 15: Resources for Food Safety Plans [May need to move after Hazard Analysis] TBD 24 Chapter 16: Putting it All Together? Resources for Food Safety Plans...................................................TBD 25 26 Appendix 1: FDA Regulation on CGMPs and Hazard Analysis and Riskbased Preventive Controls for Animal Food (FSMA Sec. 103) ..........................................A1-1 27 Appendix 2: Food Safety Plan Worksheets .............................................................................................A2-1 28 Appendix 3: Food Safety Plan for Dry Animal Food Example .................................................................A3-1 29 Appendix 4: Food Safety Plan for Liquid Animal Food Example .............................................................A4-1 30 31 32 33 34 35 Appendix 5: Food Safety Plan for Minerals, Vitamins, & MicroIngredients in Animal Food Example ..................................................................................A5-1 Appendix 6: Food Safety Plan for Animal Co-products in Animal Food Example................................................................................................................................A6-1 Appendix 7: Food Safety Plan for Plant Co-products in Animal Food Example A7-1 TBD Summary • Wet grain; lower and more variable test weight possible. Other risks depend on weather from here on. Watch out for harvest on warm days. • Carryover 2014 will create complexities. Do not mix years. Separate by high-low test weight if you can. Composite samples! • Some grain will be outside. Mix of corn and soybeans at harvest may shift somewhat. • Basic grain science principles still apply. Where To Find Us… Analytical Programs Quality Management Systems