Sanitation standards

advertisement

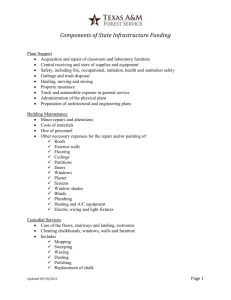

Sanitation Standards Walls/Electrical Boxes/Windows 1. All walls should be constructed of a smooth, nontoxic, easily cleanable surface that is impervious to water, sanitizers, etc. 2. Walls should be free of cracks and holes, which may harbor pests and reduce cleaning efficiencies. 3. Walls should be free of dust, dirt, product accumulation, and flaking paint. 4. Walls should be sealed at the wall–floor juncture. 5. All walls should be sealed around the openings through which equipment, pipes, or other items pass. 6. All walls should be free of dust, dirt, and food accumulation. 7. All windows should be in good repair, with no broken panes of glass. 8. All windows should be clean and free from dust, dirt, and mold. 9. All electrical boxes mounted to walls should be in good repair, free of rust and flaking paint, and mounted flush and caulked. 10. Electrical boxes should be free of dust, dirt, and food accumulation inside and out. 11. Electrical boxes should be in good repair with no rust or flaking paint and should be tightly sealed to prevent insects from entering. Ceilings 1. All ceilings should be constructed of a smooth, nonabsorbent, easily cleanable material. 2. All ceiling surfaces, as well as overhead installations or structures including ventilation units, light fixtures, electrical raceways, piping, etc., should be clean and free of product buildup, dust, mold, webbing, rust, and peeling or flaking paint. 3. All ceiling surfaces and overhead installations should be free of condensation. 4. There should be no evidence of or active water leaks on ceilings. 5. Insulation material used on overhead lines should be in good repair, smooth, nonabsorbent, and easily cleanable. 6. Nails, staples, or screws should not be used to secure ceiling material in processing, ingredient, or packaging areas. 7. No strings, ropes, wires, or tapes are to be used as pipe or line supports. Floors 1. Floors should be well drained, smooth, and clean, with no open cracks, holes, or broken areas. 2. All perimeters should have an uncluttered 18-inch wide strip to assure cleanliness, allow proper inspections, and comply with fire regulations. 3. Floors should be maintained in a clean condition with no excessive accumulations or static buildup of product. 4. Concrete floors should not be cracked or eroded, which causes absorption and unclean surfaces. 5. There should be no holes, missing concrete, or low spots causing standing water. 6. Drains should have traps and drain covers and should be maintained in clean condition, with care taken to keep water in the trap and prevent objectionable odors. 7. All cracks at the floor–wall junctures must be sealed to prevent product buildup and possible insect harborage. Doors 1. All doors should be tight fitting, clean, and in good repair. 2. Doors should be self-closing if open to the outside. 3. If the door is open, it should be equipped with an effective air curtain or strip door. 4. Doors should be tight fitting at the bottom to preclude the entrance of insects and rodents. 5. All holes in hollow wood or metal doors must be sealed to prevent harborage inside the door. Ventilation 1. Adequate ventilation in the processing area should be provided to maintain proper environmental and sanitary conditions for equipment, ingredients, finished goods, and packaging materials. 2. All systems should be cleanable, function properly, and be designed in a manner to prevent product contamination from condensation, mold, bacteria, insects, dust, and odors. 3. Objectionable odors, fumes, or vapors should not be present. 4. All fans, fan guards, duct work, louvers, and heat/air conditioning units should be clean and in good repair. 5. All ceiling-mounted fans or vents should have properly functioning, selfclosing louvers and should be screened to prevent insect entry. 6. All critical processing areas should be maintained under positive air pressure to prevent dust, flying insect entry, and cross-contamination. 7. All filters and screens used in ventilation systems should be routinely inspected and replaced or cleaned as necessary. 8. All toilet and locker room facilities should be vented mechanically to the outer air. 9. Condensation should not be present on walls or ceilings. Unessential Items 1. Unessential items are items that, when not stored in their proper places, contribute to poor housekeeping and pest control problems. These should be properly managed and stored. 2. Brooms, squeegees, and mops should have hangers and should be kept off the floor. 3. Small articles such as pencils, knives, fuses, and tools should not be left in or on electrical panels, switchboards, processing equipment, etc. 4. Idle equipment should be removed from processing areas and stored in a clean fashion. 5. Obsolete equipment should not be allowed to accumulate to the point of causing housekeeping or pest control problems. Equipment Maintenance , Design, and Installation 1. All equipment should be designed in a manner to fulfill its use effectively and efficiently while protecting the product from contamination. 2. All equipment should be of food-grade, smooth, impervious, nontoxic, nonabsorbent, and corrosion-resistant material where it has direct product contact. 3. All non-food-grade materials, such as wire, tape, string, wood, and cardboard, should not be used as a temporary design or repair. 4. All equipment should be free of rough surfaces and cracked walls where products may become static and make cleaning difficult. 5. All equipment should be free of oil leaks and excessive grease buildup on bearings and motor housing where it may contaminate product. 6. Equipment should be constructed in a manner to preclude metal-tometal contact. 7. Appropriate lids/covers should be provided to protect the product from contamination. 8. All food equipment should be installed in a manner to provide easy access for cleaning and inspections. 9. Equipment should be free of flaking paint and rust. 10. Conveyor belts should be free of loose string, metal clips, and loose pieces of rubber. 11. All processing equipment should be free of leaks at valves, gaskets, fittings, etc. 12. Thermometers, recording charts, and pressure gauges should be provided where applicable. They must be in good working order and easily accessible. 13. Equipment should be designed to preclude or divert condensation away from products and product contact surfaces. 14. All equipment should be designed to eliminate areas where products may become static. 15. All grease, oil, other lubricants, and cleaning supplies must be acceptable for food use (food grade) by the FDA/USDA. Stock Arrangement 1. All stock should be stored 18 inches from the wall and 5 inches off the floor. 2. All stock should be stored in a clean and dry environment. 3. Finished goods, raw materials, and quarantined damaged goods should be stored separately. 4. All stock should be stored in an orderly manner and properly stacked to prevent damage. 5. All partially used ingredient or packaging containers should be properly resealed or covered to preclude contamination. 6. All pallets, racks, and shelving should be clean and in good repair. 7. All damaged finished products should be disposed of in a timely manner. 8. All stock should be rotated on a first in, first out (FIFO) basis. 9. Finished products, packaging material, equipment, or ingredients should not be stored in close proximity to any chemicals, cleaning compounds, pesticides, or odorous materials. Objectionable Odors 1. No objectionable or abnormal odors should be present. 2. Rotten or spoiled food should be removed as they can result in objectionable odors and create other hazards. 3. All strong chemical odors, which could contaminate food, should be prevented. Equipment Cleanliness 1. All processing equipment should be maintained in a clean and sanitary manner. 2. Each piece of equipment should have written procedures for complete breakdown and cleaning. 3. All equipment/utensils should be stored in a sanitary manner when not in use. 4. All equipment should be cleaned and sanitized on a regular schedule that ensures the wholesomeness of the product by reducing bacterial loads. 5. All cleaning procedures should be followed as outlined in the cleaning manual. 6. Valves, gaskets, and pumps should be maintained in a clean and sanitary manner. 7. All reusable ingredient containers should be thoroughly cleaned before reuse. 8. No steel wool or metal sponges should be used in the cleaning of equipment. Product Protection 1. All ingredients, packaging material, and finished products should be handled, stored, or processed in such a manner as to assure a safe, wholesome, and unadulterated product. 2. All pesticides should be stored in a locked area and separated from all ingredients, cleaning material, equipment/utensils, and sanitizers. 3. All sanitizers, cleaning compounds, and chemicals should be stored separately from all ingredients, packaging material, and finished products in a manner to prevent any contamination. 4. There should be no flaking or peeling paint, static product, soil buildup, or rust on or above product zones. 5. All products or product containers should be adequately protected to preclude contamination. 6. There should be no condensation above product zones. 7. All conveyor belts in direct product contact should be constructed of a nontoxic and nonabsorbent material and should be clean and in good repair. 8. Lights should be provided with adequate shielding to protect from breakage. 9. Wood, cardboard, or other absorbent materials should not be used for product contact surfaces. 10. Air used for conveying product or packaged materials should be filtered, clean, and oil free. 11. Glass should not be used in, above, or near processing or ingredient areas. 12. All gasket material should be nontoxic, nonabsorbent, and in good condition (not torn, frayed, or deteriorated). 13. Pressure cleaning/sanitizing should not be conducted near, on, or above product zones during processing or packaging. 14. All tanks, vats, and blenders should be covered. 15. All product piping, pumps, and other equipment should be capped or closed when not in use and stored in a sanitary manner. 16. All partially used or damaged ingredient containers should be properly resealed in a manner to protect against contamination. 17. Product containers should not be used for purposes other than their intended use. 18. All product and ingredient containers should be covered and properly identified. 19. All tanks, vats, and kettles should be self-draining. 20. All bearings should be properly protected, designed, and/or constructed so that no lubricant can leak, drip, or be forced into the product zone. 21. A program should be developed and maintained that provides adequate means of eliminating foreign material, metal, etc. in finished products (e.g., metal detectors, in-line filters, screens, magnets). Hand-Washing Facilities 1. An adequate number of hand-washing stations should be provided within the processing area. 2. All hand-washing stations should be maintained in a clean condition. 3. Single-service towels, tempered water, dispenser soap, and proper disposal should be provided at each hand-washing station. 4. A sign at each hand-washing station that instructs employees to wash their hands prior to returning to work should be conspicuously posted. 5. Hand-sanitizing stations should be provided where deemed necessary. Toilet Facilities 1. Employees should be provided with clean, sanitary, properly functioning toilet and hand-washing facilities. 2. All toilets, urinals, and hand-washing facilities should be clean and properly functioning. 3. Hand-washing stations should have sufficient pressures of both hot and cold water. 4. Hand-washing soap, in a suitable dispenser, must be provided at each basin. 5. An adequate supply of toilet tissue and single-service towels should be provided. 6. Doors to toilet facilities should be self-closing and should not open directly into processing, ingredient, or packaging areas. 7. There should be no clogged drains or overflowing toilets. 8. Legible signs should be posted conspicuously in all toilet facilities directing employees to wash their hands before returning to work. 9. All walls, ceilings, and floors should be clean and in good repair. 10. Waste containers should be provided for used towels or other waste and should have self-closing covers. 11. All toilet facilities should be mechanically ventilated to outer air. Surroundings 1. The growth of weeds and tall grass along the building perimeter should be arrested. 2. The surrounding premises should be free of standing water or other drainage problems. All storm sewers and catch basins should be kept clear and operative. 3. The area should be free of droppings, tunneling, or any other signs of rodent activity. Rodent traps should be maintained in an orderly fashion. 4. There should be no apparent signs of pest activity immediately surrounding the building. 5. All roads, lots, and yards should be adequately paved and maintained. 6. All scrap, pallet, equipment, etc., should be stored off the ground and away from building walls. 7. Excessive amounts of scrap or idle equipment should be disposed of to reduce pest activity. 8. Any outside waste compactor/disposal area should be clean and properly maintained. 9. Suitable covers should be provided for outside waste containers. The surrounding area should be free of paper, trash, and litter. 10. The areas under and around loading docks are to be kept clean and uncluttered. 11. The building roof should be free of standing water, product dust, accumulated filth, and unessential materials. 12. There should be no signs of pest or rodent activity on the building roof.