LESSON THIRTEEN

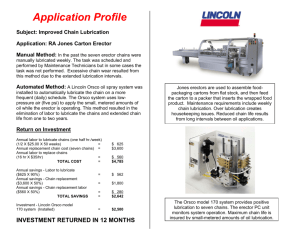

advertisement

LESSON THIRTEEN LUBRICATING OIL SYSTEM 1. PRIMARY PURPOSE OF LUBRICATION To keep a clean layer of lubricating oil film / luboil film between the contacting surfaces of the running parts / moving components in order to prevent friction, heat & metal-to-metal wear / abrasive wear. 1. PRIMARY PURPOSE OF LUBRICATION To keep a clean layer of lubricating oil film / luboil film between the contacting surfaces of the running parts / moving components in order to prevent friction, heat & metal-to-metal wear / abrasive wear. 2. SECONDARY PURPOSE OF LUBRICATION 2.1 COOLING In passing through the engine, part of the heat is absorbed / picked up by the circulating oil. Therefore, it is made to pass through the cooler before being recirculated. 1. PRIMARY PURPOSE OF LUBRICATION To keep a clean layer of lubricating oil film / luboil film between the contacting surfaces of the running parts / moving components in order to prevent friction, heat & metal-to-metal wear / abrasive wear. 2. SECONDARY PURPOSE OF LUBRICATION 2.1 COOLING In passing through the engine, part of the heat is absorbed / picked up by the circulating oil. Therefore, it is made to pass through the cooler before being recirculated. 2.2 NEUTRALISATION OF ACID PRODUCTS OF COMBUSTION (sulphuric acid) 1. PRIMARY PURPOSE OF LUBRICATION To keep a clean layer of lubricating oil film / luboil film between the contacting surfaces of the running parts / moving components in order to prevent friction, heat & metal-to-metal wear / abrasive wear. 2. SECONDARY PURPOSE OF LUBRICATION 2.1 COOLING In passing through the engine, part of the heat is absorbed / picked up by the circulating oil. Therefore, it is made to pass through the cooler before being recirculated. 2.2 NEUTRALISATION OF ACID PRODUCTS OF COMBUSTION (sulphuric acid) 2.3 CLEANING Washing away of wear detritus due to surface rubbing / friction. Therefore, the oil is filtered and centrifuged. Oil also cleanses hot moving parts from carbonaceous deposits. 2.4 SEALING This is the case with the piston & liner where the oil provides a gas seal sa well as lubrication. 2.4 SEALING This is the case with the piston & liner where the oil provides a gas seal sa well as lubrication. 2.5 PREVENTION FROM CORROSION Hot corrosion is caused by vanadium Cold corrosion is caused by sulphur 2.4 SEALING This is the case with the piston & liner where the oil provides a gas seal sa well as lubrication. 2.5 PREVENTION FROM CORROSION Hot corrosion is caused by vanadium Cold corrosion is caused by sulphur 3. REQUIREMENTS FOR A TROUBLE-FREE ENGINE OPERATION 3.1 The type of lubricating oil recomended by the manufacturer must be used. 3.2 The lubricant to be supplied in proper qantities & at the right temperature. 3.3 Provisions must be made to remove any impurities entering the system. 4. LUBRICATING SYSTEM DIVISIONS 4.1 THE INTERNAL DIVISION OR ENGINE PART OF THE SYSTEM: Passages / ducts & piping. 4. LUBRICATING SYSTEM DIVISIONS 4.1 THE INTERNAL DIVISION OR ENGINE PART OF THE SYSTEM: Passages / ducts & piping. 4.2 EXTERNAL PART OF THE SYSTEM: Sump, pumps, coolers, strainers & filters and purifiers. This system is of pressure type or forced lubrication type. 4. LUBRICATING SYSTEM DIVISIONS 4.1 THE INTERNAL DIVISION OR ENGINE PART OF THE SYSTEM: Passages / ducts & piping. 4.2 EXTERNAL PART OF THE SYSTEM: Sump, pumps, coolers, strainers & filters and purifiers. This system is of pressure type or forced lubrication type. 5. LUBRICATING SYSTEMS IN LARGE MARINE DIESEL ENGINES OF CROSSHEAD CONSTRUCTION 5.1 A TOTAL LOSS SYSTEM ( feeding the cylinders ) 4. LUBRICATING SYSTEM DIVISIONS 4.1 THE INTERNAL DIVISION OR ENGINE PART OF THE SYSTEM: Passages / ducts & piping. 4.2 EXTERNAL PART OF THE SYSTEM: Sump, pumps, coolers, strainers & filters and purifiers. This system is of pressure type or forced lubrication type. 5. LUBRICATING SYSTEMS IN LARGE MARINE DIESEL ENGINES OF CROSSHEAD CONSTRUCTION 5.1 A TOTAL LOSS SYSTEM ( feeding the cylinders ) 5.2 A CIRCULATING SYSTEM ( lubricating the running gear & cooling the piston ) 6. DESCRIPTION OF A LUBRICATION PROCEDURE L.O. pressure pumps draw the oil from the drain tank / lub oil tank / pan through the suction strainers. The drain tank is fitted with a level gauge. Pumps discharge oil through fine filters to the cooler ( the discharge pressure ensures that there will be no leakage of salt water into the oil in the event of faulty cooler.) L.O. thermostatic valve, mounted on the cooler, regulates the oil temperature flow of either the lubricating oil or the cooling water. Regulating valves control the oil distribution and its pressure in all moving components. Pressure gauges are fitted before and after the filter(s) The system is fitted with a number of alarms: pressure loss alarm, oil level alarm in drain tank, temperature alarm, pressure relief valves ( usualy mounted at pump discharge.) Oil should be permanently purified at sea. It may be also heated to assist purification.