2 - Precision Parts

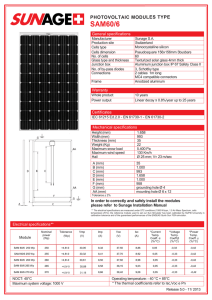

advertisement

Note of drawing-no 700A.1702.015-1 complete machining CNC Optional material GG 20-25 1. Casting bevel not more than 2° in plus 2. Not dimensioned casting radii not more than 8 mm 3. general tolerances a) For casting : according to GTB 16 DIN 1686-1 b) For machining: H14 ; h14 IT14/2 (means half of tolerance IT14) 4. 5. 6. Difference of parallelism from axis of hole “C” which based on surface “Б” not more than 0,25 mm, on the length 150 mm 7. Maximum tolerance for mismatch of hole-axis “C” to “Л” 0,5 mm 8. Measurement “E” to make from hole-axis “C” until hole-axis “Б” from counterpart 700A.17.02.010-2 9. Maximum tolerance for parallelism of hole-axis “B” and “Г” and for corresponding holeaxis “B” and “Г” from counterpart 700A.17.02.010-2 not more than 0,15 mm 10. Measurement “У” to make from hole-axis “Л” until hole-axis “Б” from counterpart 700A.17.02.010-2 11. Measurement “Ф” to make from hole-axis “Ц” until hole-axis “Б” from counterpart 700A.17.02.010-2 12. Sharp edges not allowed Chamfer missing on “A1” is allowed 13. 14. – Two holes Ø8 A2a. +0,022 machine together with counterpart 700A.17.02.010-2, whereby the notes: 8,9,10,11 have to be realize. After it the assembled part (box +cover), have to be marked with a serial number, for right use maximum tolerance for mismatch of hole-axis Ц= 3xM10, not more 0,25 mm maximum tolerance for mismatch of hole-axis 2xM8, not more 0,25 mm maximum tolerance for mismatch of hole-axis hole 14xØ11, not more 0,25 mm