Protein Pharmaceuticals

advertisement

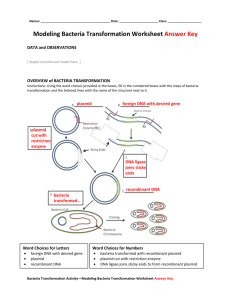

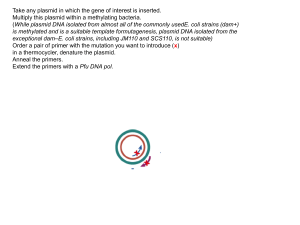

Protein Pharmaceuticals (II) “Recombination and Production” Dr. Aws Alshamsan Department of Pharmaceutics Office: AA87 Tel: 4677363 aalshamsan@ksu.edu.sa Objectives of this lecture By the end of this lecture you will be able to: 1. Recognize the advantages of recombinant over naturally-isolated proteins 2. Choose proper vehicle for recombinant protein production 3. Compare different methods of protein production Polypeptides and Proteins • Most protein pharmaceuticals today are recombinant products – Cheaper, safer, abundant supply Six-Step Process 1. 2. 3. 4. 5. 6. Isolation of gene of interest Introduction of gene to expression vector Transformation into host cells Growth of cells through fermentation Isolation & purification of protein Formulation of protein product Requirements for recombinant protein production Vector Plasmid Gene Insulin Host E. coli pUC18 Selectable marker a gene (antibiotic resistance) when expressed on plasmid will allow host cells to survive Polylinker (multiple cloning site MSC) is a many short segment of DNA which contains (up to ~20) restriction sites Promoter is a short DNA sequence which enhances expression of adjacent gene Ori origin of replication is a particular sequence where replication is initiated Restriction Nucleases Enzymes that cut double-stranded DNA at specific recognition nucleotide sequences known as restriction sites (palindrome) مودته تدوم لكل هول *** وهل كل مودته تدوم Ligases • DNA ligation is the act of joining together DNA strands with covalent bonds with the aim of making new viable DNA or plasmid • T4 DNA ligase has the unique ability to join sticky and blunt ended fragments DNA Recombination Choice of production vehicle • In principle, any protein can be produced using any genetically engineered organism Bacteria Yeast Mammalian Recombinant Protein Expression Systems • • • • • • • Escherichia coli and other bacteria Pichia pastoris and other yeasts Baculovirus Mammalian cell culture Plants Animals Cell free Choice of Expression System • Choice depends on size and character of protein – Large proteins (>100 kD)? Choose eukaryote – Small proteins (<30 kD)? Choose prokaryote – Glycosylation essential? Choose baculovirus or mammalian cell culture – High yields, low cost? Choose E. coli – Post-translational modifications essential? Choose yeast, baculovirus or other eukaryote Choice of Expression System • Not every type of protein can be produced by any cell type Prokaryotic Eukaryotic Eukaryotic Bacteria Yeast Mammalian Concentration High High Low Molecular weight Low High High Secretion No Yes/No Yes Incorrect Correct Correct Glycosylation No Incorrect Correct Retrovirus No No Possible Endotoxin Low risk Viruses Production Quality Low Moderate High Scale-Up Capacity High High Low Protein Feature Folding Contamination Cultivation Method • The culture method will determine the separation and purification methods. • For research (small scale): – Cell culture flasks • For productions (large scale): – Fermentors and Bioreactors Growth of Microorganisms • Culture medium • Oxygen • Temperature control Culture Media • It is important to provide nutritional conditions that exist in bacterial natural habitat. • Common components: • • • • • • Water Source of carbon and energy Source of nitrogen Trace elements Growth factors Buffer Terrific Broth • Formulation per one liter: • 12 g Peptone (peptic digest of casein) or Tryptone (tryptic digest of casein) • 24 g Yeast Extract • 9.4 g dipotassium hydrogen phosphate • 2.2 g potassium dihydrogen phosphate • 4 g Glycerol • Water • Phenol Red Common Media • Commonly used bacterial E.coli culture media: • • • • • • • LB (Luria Bertani) Miller broth (1%NaCl): 1% peptone, 0.5% yeast extract, and 1% NaCl LB (Luria Bertani) Lennox Broth (0.5% NaCl): 1% peptone, 0.5% yeast extract, and 0.5% NaCl SOB medium (Super Optimal Broth): 2% peptone, 0.5% Yeast extract, 10mM NaCl, 2.5mM KCl, 10mM MgCl2 , 10mM MgSO4 SOC medium (Super Optimal broth with Catabolic repressor): SOB + 20mM glucose 2x YT broth (2x Yeast extract and Tryptone): 1.6% peptone, 1% yeast extract, and 0.5% NaCl TB (Terrific Broth) medium: 1.2% peptone, 2.4% yeast extract, 72 mM K2HPO4, 17 mM KH2PO4 and 0.4% glycerol SB (Super Broth) medium: 3.2% peptone, 2% yeast extract, and 0.5% NaCl Choice of Medium Medium Name Applications LB Miller Broth E.coli growth, culture and propagation; plasmid DNA and protein production LB Lennox Broth E.coli growth, culture and propagation; plasmid DNA and protein production SOB Medium Prepare high efficiency competent cells; plasmid DNA and protein production SOC Medium Plasmid transformation and growth of competent cells 2x YT Medium Phage DNA production TB High yield protein and plasmid DNA production SB High yield plasmid DNA and protein production Fetal Bovine Serum (Fetal Calf Serum) • Fetal bovine serum comes from the blood drawn from a bovine fetus via a closed system of collection at the slaughterhouse. Fetal Bovine Serum (Fetal Calf Serum) • Advantage: – Nutrition • Disadvantages: – – – – Contaminating proteins Variability among animals Microbial contamination (virsues / bacteria / mycoplasma / fungi) Endotoxin (even with sterile serum) • Serum-free media are preferable in large scale production Contaminants • Contamination does not always mean “dirtiness” but it may refer to the presence of unwanted materials • Contaminants can be: – Host related – Product related – Process related Contaminants Host Related Product Related Process Related Viruses, Bacteria Aminoacid substitution or deletion Growth medium components Host-derived proteins and DNA Denatured protein Purification reagents Glycosylation variants Conformational isomer Metals N- and C-terminal varians Dimers and aggregates Column materials Endotoxin Disulfied pairing variants Deamidated species Protein fragments Shake Flask Incubator Shaking increases oxygen transfer Growth of Cells Shake Flask Incubator Shake Flask Incubator • Heavily insulated, heated with thermoregulation to keep temperature within 0.5 oC • Rotatable platform to spin up to 500 rpm to facilitate aeration (dissolves N2 and O2 needed for growth) • Designed for small-scale growth Microorganisms Growth Curve Fermentors and Bioreactors • Larger scale, sustained growth requires bioreactors & fermentors • Fermentors have been used for centuries – primarily for brewing alcohol and making vinegar • Modern technology and chemical engineering principles continue to improve fermentor design Fermentor vs. Fermenter Fermentor Fermenter Bioreactors • Stirred tank reactors (mechanical agitation for aeration) • Bubble column reactors (bubbling air into media for aeration) • Airlift reactors (air and media circulate together) • Microcarrier (fixed bed) reactor (cell immobilization on macroporous bed) • Membrane bioreactor: (combination of membrane filtration process with a suspended growth bioreactor) Stirred Tank Bubble Column and Airlift Airlift reactor Bubble column reactor Fixed-bed reactor Membrane Bioreactors Nutrition • Combine conventional biological treatment processes with membrane filtration • Used widely in municipal and industrial wastewater treatment Product Waste Fermentor Scale up Stock culture Shaker flask (5-10 mL) (200-500 mL) Seed fermentor (10L to 100 L) Production fermentor (1000 L to 100,000 L) Series of fixed-bed reactor systems in different scales Production Process • The most common growth processes are: 1. Batch 2. Continuous 3. Fed Batch • The mode of feeding determines the classification of the bioreactor Batch Process • The bioreactor is only fed once • The bioreactor will be allowed to run till completion: – In aerobic batch reactors, stopping oxygen supply will turn the system anaerobic and the will be the end of the batch • Very difficult to achieve in real life because there should be no input to or withdrawal from the bioreactor even for sampling Cells Retention in Batch Bioreactor • Cells are not lost throughout the fermentation • They have time to adapt and multiply to its maximum rate in the batch bioreactor • They will completely biotransform the substrate to products provided other nutrient and environmental parameters are sustained • They will enter the stationary phase either due to limiting nutrients or accumulation of toxic products Continuous Process • The bioreactor is fed continuously • The amount of feed introduced into the bioreactor equals the removed volume • The process is sensitive and subjected to influence from various factors Cells Retention in Continuous Bioreactor • Continuous wash of cells • Cells always need to continually adapt to the input of nutrients • This is reduced if the cells are immobilized or recycled Fed Batch Process • The addition of nutrients is controlled to allow temporal variations in the supply nutrients • Possible to control the rate of growth of the microorganisms or the concentration of the biomass by controlling the feed parameters • The most common process in industry Cells Retention in Fed Batch Bioreactor • Cells are exposed to intermittence of new input of nutrients • But the cells are maintained in healthy state Feed Dosing of The Bioreactors • The stability of the composition of the microbial population depends on: 1. 2. The impact of the changes The rapidity of the microorganisms to adjust to the changes forced upon the microorganisms • Concentration, stable composition of the feed and how the feed is introduced will affect the performance of the bioreactor especially with: 1. 2. 3. 4. Very sensitive and fastidious microorganisms Very slow growers Very small bioreactors Bioreactors operated on very short retention time Now you are able to: Recognize the advantages of recombinant over naturally-isolated proteins Choose proper vehicle for recombinant protein production Compare different methods of protein production Next Lecture Purification of protein pharmaceuticals