Takt-time

Design of Cellular

Layout

Operations Analysis and Improvement

2010 Fall

Dr. Tai-Yue Wang

Industrial and Information Management Department

National Cheng Kung University

Presentation

The concept of manufacturing cells was presented as a specific case of product/process layout

The transformation requires a unique development and implementation methodology

The use of cells creates a unique set of production modules

Transforms the factory into a group of self-managed sub-factories or modules.

Presentation

This chapter presents some design and analysis tools focused on getting a company ready to progress to cellular manufacturing.

Including line balancing techniques.

Introduction

The first moveable assembly line was created by

Ford to manufacture the Ford Model T.

A capstan and a thick cable to move the cars between assembly stations.

Before this development -> fixed position layout.

The required time to manufacture a car was reduced from 13 hours down to 6 hours.

Produced only identical black Ford Model T cars.

It was the color (Black) that dried the fastest.

Thereby allowing many Americans to afford a new car.

Introduction

Ford used many of the specialization ideas developed by Adam Smith

Nail manufacturing

Better having one worker manufacturing the head and another worker the tip.

Specialization and task decomposition lead to the birth of new professions.

Industrial engineers were devoted to component task design and to manufacturing scheduling.

Introduction

Alfred Aloan (General Motors) enhanced Ford’s work

Mix different models on the same assembly line.

During the 1960’s and 1970’s, Japan did not adopt the Ford, Aloan and Taylorist way of working

They expanded worker involvement to handle a variety of manufacturing processes.

Mass production

Some products are manufactured in very large batches to satisfy mass market demand.

Food products, which are manufactured in high volume, will not be addressed in this chapter.

Other products, such as toys, cars and electrical appliances will be studied in depth.

Mass production

Mass production has two basic characteristics.

Low product price as compared with the cost of the handmade products.

Product should be as standard as possible.

Reducing the number of different replacement parts.

Reduction in the number of spare parts.

Companies must maintain a spare parts accessibility for a certain amount of years.

Mass production

Simple product assemblies reduce process time.

The cost of each article decreases.

If the complexity of a product can be increased to accommodate additional replacement part applications then the part’s utility increases.

Mass production

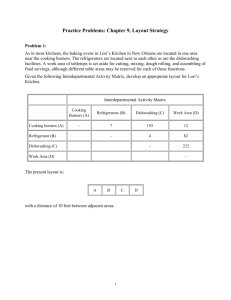

Product-Quantity (P-Q) analysis tool helps to decide the optimal plant distribution for the different products manufactured.

Using Pareto Tool.

If products quantity is large and its variety is small, massive production fits perfectly

Focused assembly lines provide the most economic production alternative.

Flow or assembly lines

The recommended way to manufacture mass produced articles is by using flow or assembly lines.

Workstations dedicated to the progressive manufacture and assembly of parts.

Integrated using materials handling devices.

Flow or assembly lines

Creating flexible cells generally requires the duplication of machines.

Invest in several simple machines with low cost.

Instead of a versatile and more expensive machine.

Flow or assembly lines

Another advantage of assembly lines is that the work-in-process decreases.

Containers with waiting parts are placed in small queues.

This design eliminates excessive inventory required when using more versatile and expensive machines.

It is more critical to have higher machine utilization of more costly equipment.

It is more difficult to manage a greater variety of incoming material.

Flow or assembly lines

The most frequently used material handling device is the conveyor belt.

Size of the product -> Overhead conveyor systems.

Each product stops a predetermined amount of time in each station (synchronized flow).

Each product is removed at a workstation to be worked on (asynchronous flow).

Island layout

Advantages.

An effective layout when considering product movement.

Multifunctional workers.

One-piece-flow.

Island layout

Disadvantages.

Worker is specialized in an island or subject.

The islands are isolated with respect to each other.

Synchronization among them can be difficult.

Cell layout design justification

The manufacturing environment has changed significantly in the past several years.

PREVIOUS CURRENT

Product

Delivery time

Size of lots

Lead time

Little variety

Not very demanding Very demanding

Large

Long

Product life cycle Long

Great variety

Small

Short

Short

Flow or assembly lines focus on high volume products

Cell layout design justification

The use of process focused systems or job shops is focused on very small volume products.

These systems maximize flexibility, but have other problems.

Cell layout design justification

Reasons to suggest the use of the manufacturing cells as opposed to process layout.

A high number of indirect workers is generally required in process layout.

A high level of work-in-process is also typical of process layout.

Product quality responsibilities are not as clear when using process layout.

Cell layout design justification

When cellular layout is properly employed…

Unnecessary product movement can be eliminated.

Product and manpower flexibility can be achieved.

A more economic production environment can be obtained.

The transition to cells is not easy.

Basic cells design nomenclature

Task -> a set of the necessary steps that the work gets decomposed into.

Is considered the smallest assignable unit to a cell.

Define the beginning and the end of the task in a precise way.

Methods and time methodologies facilitate the goal of optimizing a task.

Time study is also briefly presented in this chapter.

Basic cells design nomenclature

Workstations -> The logical organization of specific manufacturing or assembly equipment to perform task(s).

The number should be as small as possible.

Minimum workforce can be maintained along with a reduced work-in-process.

Basic cells design nomenclature

Takt-time and cycle time.

Takt is a German word for rhythm.

Is a critical term for manufacturing systems design.

Takt-time is the allowable time to produce one product at the rate a customer demands it.

This is NOT the same as cycle time.

Basic cells design nomenclature

Cycle time is the normal time to complete an operation on a product in each workstation.

Should be less than or equal to takt-time .

Takt time Tc

Useful working time in one day

Daily demand

Cycle time is the sum of the task times that a product requires at each station.

During the cell design project, it is important that the takt-time and the cycle time be as close as possible.

Basic cells design nomenclature

Takt-time and cycle time.

Takt-time can never be smaller than the largest workstation cycle time.

A rhythm becomes faster than the production system is capable of handling in the upper diagram.

Cycle time

Cycle time

A

A

B C workstation

D

B C workstation

D

E

E

Takt-time

(1 unit)

Takt-time

(1 unit)

Basic cells design nomenclature

Takt-time and cycle time.

Cycle time is a measure of how much time it takes for a particular operation.

Cycle time

Cycle time

A

A

B C workstation

D

B C workstation

D

E

E

Takt-time

(1 unit)

Takt-time

(1 unit)

Basic cells design nomenclature

Total workstation cycle time (p i

).

The sum of the process times for each one of the tasks assigned to a workstation.

Basic cells design nomenclature

Idle time (h i

)

Difference between the takt-time and the cycle time or total work at each workstation.

It can never be less than zero.

(That would imply that a station has assigned more work than the takt-time .)

Reality for many assembly companies can be quite different than theory.

(Cell flexibility allows a company to rebalance tasks where the maximum cycle time exceeds the required takt-time .)

Basic cells design nomenclature

Precedence diagram.

Precedence restrictions that exist when assembling the product.

T1 16

T2 3

T3 12

T4 8

T5 24

T6 6

Basic cells design nomenclature

Precedence diagram.

Characteristics.

There are only left to right arrows.

There are no precedence relationships between tasks in the same level.

In the determination of a level, all the tasks without precedence among those that have not be placed yet are placed in that level.

The figure also include the task duration.

Cell design methodology

The methodology to develop production cells is very straightforward.

Form product families.

Change the machines location.

Calculate the output production rate, the task assignment in each workstation and the necessary number of workers in the cell.

Planning and controlling the cell.

Cell design methodology

The difficulty lies in the high number of prerequisites needed to be able to carry out this layout transformation.

Prerequisites for cell designing

Multifunctional workers.

Determine the required space for the cells

(specially U-shaped cells).

Invest in new machinery.

Improve the set-up time of dies.

Prerequisites for cell designing

Look for simple methods for production automation.

Choose new production planning and control systems so that future planning or control of the line is not required.

Line Balancing

Main goal of line balancing techniques.

To assign tasks to workstations so that the minimum number of workstations can be achieved.

Each task needed to produce a part are assigned to only one workstation.

In each workstation the assigned work (p i

) is less than the takt-time.

The idle time is minimal.

This assignment should not violate any of the precedence relationships

Line Balancing

Line balancing for some companies may require specific algorithms.

The workers should be assigned to a fixed number of workstations.

The next methodology does not apply.

General steps in the line balancing

STEP 1. Define the tasks and their times (t i

).

STEP 2. Specify the precedence relationships

Building the precedence diagram.

STEP 3. Determine the takt-time (Tc).

Takt time Tc

Useful working time in one day

Daily demand

General steps in the line balancing

STEP 4. Calculate the minimum number of workstations (M min

).

Supposes the lower limit of the number of workstations that can be created.

M min

C t i

General steps in the line balancing

STEP 5. Choose a task assignment rule.

This is explained later on.

STEP 6. Assign tasks.

Until the assigned time is equal to the takt-time

Until it is no longer possible to assign a task due to the restrictions of time or sequence.

In this case it will be necessary to create a new workstation and continue with the assignment.

General steps in the line balancing

STEP 7. Determine the total idle time and the line efficiency.

H M c i

M

1 p i

Efficiency

M i

M

1

p i

Tc

STEP 8. If the obtained solution is not considered acceptable -> choose another assignment rule.

Line balancing--Tasks assignment rules

A task is eligible if it has not yet been assigned and all those that precede the task

(preceding tasks) have been.

It will be necessary to decide among several eligible tasks.

There are different heuristic methods.

Line balancing--Tasks assignment rules

Heuristic methods are simple rules that propose two selection criteria.

The second criteria will only be used if there are several tasks that coincide in the first criteria.

The obtained solutions can be compared by analyzing the idle time share among the workstations.

Line balancing--Heuristics

Total number of following tasks heuristic.

Among the eligible tasks -> choose the task that has the largest total number of following tasks.

If two or more tasks coincide -> select the task with the longest time t i

.

Line balancing--Heuristics

Individual durations heuristic.

Among the eligible tasks -> choose the task with the longest time t i

.

If two or more tasks coincide -> select the task that has the largest total number of following tasks.

Line balancing--Heuristics

Largest positional weight heuristic.

Among the eligible tasks -> choose the task that has the largest positional weight.

Positional weight is the sum of the task time and the time of all its following tasks

If two or more tasks coincide -> select the task with the longest time t i

.

Line balancing--Special cases

Task time larger than the takt-time .

Accept that the task dictates the takt-time .

Supposes the loss of possible product sales or to increase the number of pending orders.

Line balancing--Special cases

Solve the problem.

Divide the task into two tasks.

Analyze and define the task again.

Improve the task or the product.

In case of an assembly task incorporate an assistant.

Place two workstations in parallel.

It increases the work-in-process.

This solution will be adopted if and only if the other choices are not possible.

S1 p

1

=5

0

S2’ 0

P

2’

=10 tc=5

S3 0

S2’’ 0 p

2’’

=10

S3

S2’’

S2’

S1

0 5 10 15 20 25 30 35 p

3

=5

Line balancing in U-shaped cells

S1 S2 S3 S4 S5

The line balancing method, sometimes, causes an unequal time assignment.

The U-shaped layout, with shared tasks, helps to solve these unequal times assignment situations.

S1

S6

S2

S5

S3

S4

Line balancing in U-shaped cells

U-shaped cells avoid constant displacements to the start of the line and solves many of the island distribution problems.

S1 S2 S3

S6 S5 S4

Line balancing in U-shaped cells

Advantages.

Improves the tasks assignment by offering production rate flexibility.

The number of workers assigned can be changed at any time.

Makes easy to adapt the cycle time to the tack time without rearranging the task assignments.

S1 S2 S1 S2 S1 S2

S4 S3 S4 S3 S4 S3

S1 S2 S3

Line balancing in

U-shaped cells

S6 S5 S4

The mathematical resolution of U-shaped line balancing needs to be solved in a good way.

Solutions can be obtained through two different ways.

Observation of the workstations and their corresponding idle time.

Make the line balancing supposing a takt-time

(Tc’) equal to half of the takt-time

(Tc’ = Tc/2)

Later, bending the line.

The problem arises when the number of workstations is odd.

s1 0 s2 0 tc=10 tc’=5 s4 s3 s2 s1

0

S1 s4 0

0

5 10 15 20 25 30 35

S2 s3 0

0

U-shaped LB with a t i than Tc’ larger

6 min.

s1

8 min.

s2

6 min.

s3 s5

6 min.

s4

6 min.

t c

=12 min t c’

=6 min s5 (op1) s4 (op3) s3 (op3) s2 (op2) s1 (op1)

6 12 18 24 30 36 42 48 54 tiempo

U-shaped LB with a t i

Tc larger than

6 min.

s1 s5

6 min.

s2’

20 min.

20 min.

s2”

6 min.

s3 s4

6 min.

t c

=12 min t c’

=6 min s5 (op1) s4 (op4) s3 (op4) s2” (op3) s2’ (op2) s1 (op1)

6 12 18 24 30 36 42 48 54 60 tiempo

Group technology

Which products are grouped to create a cell?

Group technology facilitates the formation of product families.

Group technology is a tool utilized in engineering and production departments to identify similar products.

Economies of scale are achieved forming multiproduct families rather than from a single part.

Small companies can compete against bigger companies.

Offering seemingly unique products, but with numerous similar attributes.

Group technology

In some cases, alliances have taken place among different companies to manufacture new models sharing the development costs.

The goal of group technology is to reduce design costs and production costs.

Group technology

Many of the gains of group technology come from design standardization.

In some cases the components are designed in a way that allows them to be utilized in different products.

the same screw for different fastening needs.

This screw is gauged according to the most critical point.

Group technology – Product Family formation

It is usually impractical to have a manufacturing cell for each product.

investments would be bigger than the expected benefits.

Grouping products into larger families eliminates this problem.

Group technology – Product Family formation

The formation of families can suggest small design changes.

If the changes do not affect the product functionality or to the client's necessities.

Techniques to form product families.

Based on direct visual inspection.

Complex mathematical methods based on product features and shape.

Group technology - Advantages

Savings

Up to 50% for the design time.

Work-in-process by as much as 60%.

Reducing time-to-market by 70%.

Group technology - Advantages

These benefits in production come from different sources.

Reduction in the number of dies required for pressworking.

Reducing purchasing cost by clustering and grouping orders of similar components.

Scheduling simplification.

Due to the reduction on the number of product types and the formation of self-managed cells.

Group technology -

Disadvantages

Family classification consumes time and effort

Does not always lead to profitable solutions.

It can suggest erroneous changes in a product design.

The installation of the manufacturing cells demands changes in the working habits.

The responsibility is distributed among workers.

Layout changes usually require large investments.

Group technology -

Disadvantages

The duplication of some machines imply a low utilization of equipment.

Traditional business management techniques penalize these reductions in production rates.

They are based on productivity.

Time study

Time study can be defined as the methodology used to determine the standard time for an operation.

The time that a qualified worker needs to carry out a specific task, working in a normal rhythm during a work day .

Time study

The first historical works -> Fredrick Taylor’s time.

Taylor used the most qualified worker to establish the standard working time.

Educating the rest of workers to carry out the tasks in the same manner.

Taylor received opposition from labor unions.

Taylor decided to include two kinds of allowances.

Related to the workers fatigue.

Regarding variations among various worker capabilities.

Time study

Frank and Lillian Gilbreth added to the material started by Taylor.

They divided tasks into fundamental elements.

Chose the best worker for each task.

The standard time was obtained by adding the best times of each task.

Time study

Years later, Lowry, Hayrard and Stegemerten, at

Westinghouse company.

Defined a normal-worker concept which is still used today.

Poka-Yoke

TPM

Kanban

Time study

Thinking revolution

The 5S

Standard operations

One-Piece flow

Leveling

Production

JUST IN TIME

Jidoka

Multifunctional workers

SMED

Time studies lead to establishment of the work standard.

Standard time establishment has other important utilities.

The use for factory scheduling.

Providing standards for incentives systems.

Based on worker productivity.

Time study

Thinking revolution

The 5S

Poka-Yoke

Standard operations

TPM

Kanban

Jidoka

One-Piece flow

Leveling

Production

Multifunctional workers

SMED

Comparing different work methods.

Optimizing the number of workers required to achieve a schedule.

Knowing the production costs.

JUST IN TIME

Poka-Yoke

TPM

Kanban

Time study

Thinking revolution

The 5S

Standard operations

One-Piece flow

Leveling

Production

JUST IN TIME

Jidoka

Multifunctional workers

SMED

Four different methods to determine the standard time.

Time study with chronometer or videotape cameras.

Predetermined Time.

Work sampling.

Normalized times.

The first two methods are the most used.

Time study - Chronometer or videotape camera

Obtain the standard time for an operation by means of direct task observation.

Recording the time is carried out with a stop watch (chronometer) or a camcorder.

Time study - Study preparation

It is necessary to clarify that the goal is to determine the standard time, not the time that the worker is really using during the observation.

Workers typically speed up the process when they are being watched.

Once this standard time is set, it can be compared with the time typically required to carry out the operation.

The deviation between the times can be used for future improvements.

Time study - Study preparation

It is necessary to become familiarized with the process or task being studied.

Develop a layout of the working environment.

Determine the work cycle being studied.

Since significant variability may take place when the same event happens again.

Time study - Study preparation

Time study is not only a technical problem of measuring the time.

Human behavior enters the process and the operator can speed up or slow down.

Understanding and assessing the operator is a basic requirement for a successful time study.

Time study - Study preparation

Technical knowledge is only a 25% of the requirements for a time analyst.

Formulate questions in a polite manner.

Inform to the worker that the study will be used as reference.

Convince the workers to contribute in the study.

The worker should neither be criticized nor corrected while the study is being carried out.

These usually lead to an erroneous study.

Time study - Data acquisition

Use traditional stop watches.

Special chronometers (called minute decimal chronometers).

A time study should be broken in working elements.

Determine the beginning and the end of each one.

Time study - Data acquisition

Distinguish the following element categories.

Repetitive and casual (non-repetitive) elements.

Constant and variable elements.

Variable -> depends on a product characteristic.

Identify accidental elements.

Separate machine elements from worker elements.

A resource should not be penalized when the other resource is busy.

Time study - Data acquisition

Separate unnecessary and essentials movements.

Identify simultaneous movements.

Considered the longest time within them.

Time study - Data acquisition

Two different methodologies for data acquisition.

Snapback method.

The chronometer is stopped and returned to zero at the end of each task.

Continuous timing.

The time is presented in an accumulate way.

This procedure is better than the previous one.

Mainly if the videotape is used.

Time study - Data acquisition

Number of cycles to study.

There will be variations among times.

Depends on the duration of the elements and also on the accuracy required.

Usually are taken 10 readings (n’).

n

40 n ' x 2 x 2

x

2

Time study - Standard time establishment

The first stage is to eliminate the measurements due to accidents, mistakes, etc.

Observed time ( OT )

The average of the rest observations.

Time study - Standard time establishment

OT should be corrected taking into account two factors .

The speed at which the worker has done the task when the study was performed.

The possibility of maintaining the same working speed during the whole day.

Time study - Standard time establishment

A normal speed.

The time that a normal worker can reach and maintain during a theoretical working day.

Without additional fatigue.

The companies usually demand, comparing to the normal, a higher working speed.

Normal speed

100

60

75

Rhythm type or activity

133

80

100

Time study - Standard time establishment

Factors which are necessary to take into account.

Some of the factors do not depend on the worker.

Changes in the material quality.

Other factors are exclusive of the worker.

The worker's attitude regarding organization or professional know-how.

Time study - Standard time establishment

The analyst should fix a subjective value of the observed working speed.

Called the activity factor or AF .

NT observed speed rhythm speed or activity

OT AF OT

Time study - Standard time establishment ST A NT

Allowances (A).

Personal necessities vary between 5% and 7%.

Resting and recovering from exhausting tasks.

Basic fatigue -> 4%.

Weigh lifting, environmental conditions.

Unforeseen events.

Special process characteristics.

Time study - Standard time establishment ST A NT

A fixed factor (A) is frequently used

Due to the complexity of determining the value of all the suitable allowances, .

Oscillates between 13% and 15%.

Time study - Predetermined time

Determine the standard time of an operation that does not yet exist.

If the operations could be broken down in a limited number of elementary tasks…

It would be possible to set the standard time of an operation in a simple way.

There are a limited number of basic movements for workers.

Their analysis and study are carried out by predetermined time systems.

Time study - Predetermined time

Predetermined systems have the advantage of leading to more coherent standard times.

They are very difficult to implement.

Working tables can be very complex.

Do not eliminate the necessity of using the chronometer.

Machine manufacturing times and waiting times are not included in the tables

Time study - MTM System

MTM (Method Time Measurement).

Covers generic movements of a person.

Release, reach, move, turn & apply pressure, grasp, position and disengage.

Three additional movements that are also included.

Two eye movements.

Travel and focus.

A upper body movement.

13 movements that belong to the body.

Time study - MTM System

MTM (Method Time Measurement).

The combined movements and simultaneous motions are also tabulated.

Time units -> TMU (Time Measurement Unit).

1 TMU = 0,036 secs.

Simplified MTM system (MTM-2).

Leads to more accurate solutions with an error of

5%.

Leveling production

Leveling production is a prerequisites required for a cell layout transformation.

Corresponds to the production planning and scheduling strategy.

It is included in both the Just-in-time and the 20 keys (key number 16) for lean.

Leveling production

To explain this concept Tomo Sugiyama uses a military example.

The Battle of Nagashino.

Nobunaga opposed Takeda.

Nobunaga headed a thousand soldiers with muskets.

Takeda commanded a traditional army cavalry.

Takeda hoped to be able to attack Nogunaga while the muskets were being loaded.

He was not able to get in while the muskets were being loaded, and Takeda lost the battle. Why?

Leveling production

Batalla de Nagashino.

Nobugana’s victory was due to a strategy that he devised.

He divided his army into three parts so that there was continuous firing.

This strategy allowed 1/3 of his troop to be ready at all times.

A third of the soldiers were always firing at Takeda’s army.

Takeda did not find the right moment to attack

Leveling production

Nobunaga’s approach can also be applied to factory production.

In mass production systems, it is possible to calculate the takt-time.

Each product is manufactured in an independent production line.

Production scheduling is not affected by only product leveling, but with fulfilling customer due dates.

Leveling production

Initial strategy for most companies.

Carry out traditional constraintbased monthly planning to satisfy customers demand.

A large amount of inventory is produced, maintained and stored.

Leveling production

If daily planning is conducted.

The amount of generated inventory would be 20 times smaller.

Leveling production

Leveling production.

Nobunaga’s approach.

Leads to “constantly firing” different products.

This tool forces a company to change their production scheduling strategy.

Leveling production calculates the takt-time for each product.

Leveling production

The development of a feasible sequence that satisfies the demand is quite complex.

In the example presented above, it is possible to find a proper sequence.

If this sequence is repeated 10 times, it fulfils the demand.

Leveling production

Generally it is difficult to obtain a feasible

(or optimal) solution when manufacturing different products.

Production planning and scheduling in the factory should be leveled.

If cell layout has not been properly implemented, level production is not possible.

Leveling production

Leveling production forces the suppliers to level their manufacturing processes.

Otherwise, they will need to store large quantities of finished products to satisfy the demand.

This manufacturing strategy has created one of the main obstacles to the Just-in-time.

The supplier owns the inventory until the assembly plant draws items for assembly.

Leveling production

Prerequisites needed in leveling production.

Repetitive production.

Excess of capacity in productive resources.

Fixed production for, approximate, a time horizon of one month.

High inventory costs.

Low resource costs.

Multifunctional workers.

Short set-up times.

Multifunctional workers

Until the 1960s the standard was for each machine to have a dedicated worker ->

Specialization.

The main productivity concern for a company.

Multifunctional workers

Today’s market demands workers that are familiar with more than one process.

Production workers need to carry out operations that may involve multiple departments.

Quality and maintenance tasks.

1

9

14

7

6

2

17

18

19

11

10

12

16

5

4

20

13

15

8

3

Multifunctional workers

Multifunctional training has become a standard for today’s factory worker.

Multifunctional workers are an important key in the Just-in-time philosophy as well as in the 20 keys

(key number 15) for Lean.

Thinking revolution

The 5S

Poka-Yoke

Standard operations

TPM

Jidoka

One-Piece flow

Multifunctional workers

Kanban

Leveling

Production

SMED

JUST IN TIME

Multifunctional workers - Task rotation

Multiple advantages.

Reduction in work-related accidents.

Improves the relationships among labors.

Facilitates knowledge sharing.

Uncover expert workers in each task.

Should instruct other less skilled workers.

Multifunctional workers - Task rotation

Training programs.

Used to create comfortable learning environments.

Promote other employees to self-improvement.

incentives to workers that shown an interest in learning and sharing their knowledge.

Always supposes a reduction in the company’s production capacity.

Workforce optimization

Thinking revolution

The 5S

Poka-Yoke

Standard operations

TPM

Jidoka

One-Piece flow

Multifunctional workers

Kanban

Leveling

Production

SMED

JUST IN TIME

Is a tool that is part of the Just-in-time philosophy

The goal of this tool is to define how many people are necessary to make what it is necessary to make.

Manufacture with the minimum number of workers.

Workforce optimization

Thinking revolution

The 5S

Poka-Yoke

Standard operations

TPM

Jidoka

One-Piece flow

Multifunctional workers

Kanban

Leveling

Production

SMED

JUST IN TIME

One of the optimization principles is not to assign a fixed number of workers to a line.

Multifunctional workers.

It is possible to use the available workforce in the best possible way.

Workforce optimization -

Example

Supposing a cell formed by five workstations.

Tasks can be redistributed so that the need of one workstation is eliminated.

Once achieved the first objective it is time to reduce the workforce by means of a better tasks assignment.

Takt-time

1 2 3 4 5

1 2 3

Takt-time

4 5

Workforce optimization -

Example

Takt-time

1 2 3 4 5

Takt-time

1 2 3 4 5

After redistributing the tasks, it is important to improve the task by eliminating a second workstation.

Instead of distributing the work among the four workstations.

Workforce optimization

Part movements

Waste

Worker movements

Net operation

The needed time to carry out a task can be decreased by eliminating waste and operations that do not add any value to the product.

This is the way to eliminate the need of a fourth worker in the presented cell.

There are method improvements tools that will be analyzed in a later chapter.

Summary

In this chapter the methodology and the requirements for cellular layouts’ design have been developed. U-shaped layout has been chosen as best cell design although this layout requires multifunctional workers in order to be efficient. In addition, this chapter has presented some methodologies such as time study and group technology that must be used to effectively carry out this project.