Overview Presentation

advertisement

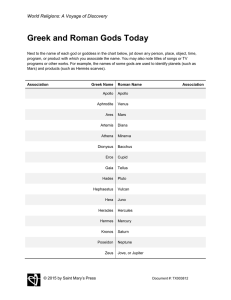

The Mars Homestead Project ™ A Project of the non-profit Mars FoundationTM Our Mission: To design, fund, build and operate the first permanent settlement on Mars, opening the new frontier! Presented by: Bruce Mackenzie Bruce@MarsHome.org (781)944-7027 Partial list of design team: April Andreas – Mars Cookbook James Burk – Webmaster Frank Crossman – Polymers & Glass Robert Dyck – Refining, Space Suits Damon Ellender – Metals, Gas Plant Gary Fisher – Waste Treatment Inka Hublitz – Agriculture William Johns, MD – Psychology Mark Homnick - Mgr K. Manjunatha – IT / IC / Comm Joe Palaia – Electrical, Nuclear Georgi Petrov - Architecture Richard Sylvan, MD. - Medical To Arrive, Survive & Thrive! 1 Outline • We need your help! • Initial Destination Mars • Task Forces • How do we get from vision to reality? • Prototype Projects • A vision for Martian settlement • R&D & Outreach Center • Comparing this world and the next • Future Directions • Conclusion • Resources to build a new home Pat Rawlings, Inevitable Descent 2 Mars settlement will open up the solar system to humanity and life Asteroids can support Trillions of people… … someday But, Start with Mars, reasons: 1. Water for Food 2. Carbon for Food 3. N2, nutrients for Food 4.a. Carbon – for Polymers 4.b. Water for industrial processing 4.c. Atmosphere, replenish air leaks, cooling 4.d. Dirt, raw materials, Si, Fe, Al, SiO, O2, 4.c. 24.6 hour day 4.d. …. Learn: Interplanetary travel, Life support, Bootstrap Manufacturing, 3 How do we get from Vision to Reality? • Feasibility study • Prototype Projects • Research & Outreach Center • Change Mindset • Mars Mission • Permanent Mars Settlement • Settle Luna, Asteroids 4 Vision - The Hillside Base • Built largely from local materials • ~90% self-sufficiency by mass • Industrial capabilities enable settlement of the frontier Graphic by Georgi Petrov. Copyright © 5 Comparing this World, and the Next… Dist. to Sun Diameter Tilt of Axis Length of Year Length of Day Gravity Temperature Range Atmospheric Pressure Atmosphere Gases Number of Moons Polar Ice Caps Largest Canyon Highest Point Lowest Point Mars Earth 225 million km 6,786 km 25 degrees 687 Earth Days 24 hours 37 minutes 3/8 G -127 C to 17 C 7 mb (ave) 95% CO2 2 (Phobos & Deimos) Water Ice & Dry Ice (CO2) Valles Marineris width of continental US Olympus Mons - tallest known volcano. 27km above Mars average. 150 million km 12,756 km 23.5 degrees 365.25 Days 24 hours 1G -88 C to 58 C 1013 mb (ave) 78% N2, 21% O2 1 (Luna) Water Ice Hellas Basin, 4km below Mars average. The Grand Canyon Mount Everest. 8.848 km above sea level. Mariana Trench 11.022 km deep. 6 Selected Location: Candor Chasma Valles Marineris 69.95W x 6.36S x -4.4km 7 Possible locations for landing zones that don’t overfly the settlement Settlement Location 8 Settlement Construction Staging Plan Phase1 • Completely Robotic. No humans on site. • Timeframe : First 2 years. • Objectives : Deploy first nuke, well drilling equipment, gas plant. Establish water well and initial gas reserve. Phase 2 • 4 People on Site • Timeframe : Second 2 years. • Objectives : Deploy and setup mining / refining / manufacturing equipment. • MRM production runs. Produce material needed for settlement construction. Phase 3 • 8 People on Site • Timeframe : Third 2 years. • Objectives : Continued MRM as needed. Settlement shell construction. No settlement electrical loads yet. Construct shell around agriculture, manufacturing & nuke BOPs. Phase 4 • 12 People on Site • Timeframe : Fourth 2 years. • Objectives : Finalized settlement construction. Commissioning. All settlement loads coming online. 9 Temporary Habitats Graphic by Georgi Petrov. Copyright © 10 Graphic by Georgi Petrov. Copyright © 11 Graphic by Georgi Petrov. Copyright © 12 Standardized Modules Graphic by Georgi Petrov. Copyright © 13 Lower Level Graphic by Georgi Petrov. Copyright © 14 Regolith Overburden holds internal air pressure • B-B Cross Section Thru Greenhouse and Kitchen 15 16 Lower Level Graphic by Georgi Petrov. Copyright © 17 Upper Level Graphic by Georgi Petrov. Copyright © 18 First Permanent Settlement for 12 People Build Phase 1 100m Graphic by Georgi Petrov. Copyright © 19 Settlement Expansion to 36 People Build Phase 3 Build Phase 2 100m Graphic by Georgi Petrov. Copyright © 20 21 Resources to build a new home • What do we have to work with? • What you bring from Earth • Local Resources (Atmosphere, Water & Soil) • Humans & robots working synergistically 22 Resources we bring from Earth 250 metric tons of Cargo / Habitat / People • Robots, automation systems • People – Temp. living quarters – Life Support & dry food • Power System – Nuclear Reactors, backup solar – Electrical distribution components • Construction Equipment • Mining, Excavation, Hauling Equipment • Refining Equipment • Manufacturing Equipment – Gases, chemicals, metals, plastics, ceramics, masonry, glass • Other high-tech / low mass / or items to manufacture items • Equipment & material scavenged from Descent Craft – Control systems, wiring, actuators, sensors, metal, parachutes, etc. 23 Technologies / Building Materials 24 Martian Atmosphere 25 Use of Atmospheric Gases Atmospheric Composition 95.3% carbon dioxide (CO2) 2.7% nitrogen (N2) 1.6% argon (Ar) 0.15% oxygen (O2) 0.03% water vapor (H2O) Output Products of Gas Plant • Oxygen • Habitat buffer gases (N2/Ar mix) • Methane (CH4) & H2 Fuel • Longer Chain Hydrocarbons • Plastics (including epoxy) Pressure: 5-7mbar 26 Gas Liquefaction and Storage CO2(lr) CO2(l ) CO2(ll) Atmosphere Air Primary Compression 20 Bar Air Cooling N2/Ar2 Secondary Compression 50 Bar N2/Ar2 1st Stage Cooling N2 2nd Stage Cooling (Optional0 N2(l) 1 2 3 4 LIN Storage N2 5 Ar2(l) CO2(l or s) Ar Storage CO2 Storage Ar S c N2 r N2 Usage u b S c Ar2 r Ar Usage u b CO2 Storage Sabatier Processes Process Flow Diagram-Mars Air Separation and Compression Wednesday, January 19, 2005 27 Martian Water By R.S. Murray 28 29 Greenhouse Water Use Graphics by Georgi Petrov. Copyright © 2005 30 WRS - Waste Recycling System, (portion of system) Fig 2 - EPU Flow Diagram Condenser/RO + Makeup Water WRS Potable Water Tanks 3@ 10,000 L Potable Water Uses: Laundry Cleaning Food Preparation Drinking Shower, Etc. Tank #1 WRS Inflow Gray Water Tank 10,000 L To Condenser/RO Aquaculture Tanks 4 @ 2,000 L P8 Sludge to CS P1 Tank #3 Trickling Filter P3 Tank #2 Trickling Filter Reservoir 3,000 L Tank #4 Turf Scrubber Reservoir 1,500 L Tank #5 Algal turf scrubber 250 L Irrigation Water Tank 8,000 L P2 GREENHOUSE Nutrient Tank 8,000 L Tank #6 Aerobic 3,000 L Tank #8 Clarifier 3,000 L Tank #7 Aerobic 3,000 L Filter Thru Compost COMPOST SYS 5 micron filter Ozone Generator Injector P6 Tank #9 Ozone/UV Column 200 L P5 P4 P7 Spent Sand to CS WRS Outflow Storage Tank 10,000 L 31 Martian Soil by Robert-Murray 32 33 Glass Process Diamond Glass Cutter 1m2 (200kg) 18 cuts/day Transport and Storage Stacked on Trailer and Moved by Rover 18 1mx1mx5mm panes per day 1kW Power Requirement Cooling Lehr 2mx2mx1m (built from local Bricks, Refractory) 200K 200kg/day Cooling CO2 2.5 kW Heating Methane/O2 ?? kW Glass Supply(Molten) 1200-1400C 200kg/day Float Bath (Pilkington Process) Required a 20mm layer of Sn(.16m3(1166kg)) 2mx4mx1m (built from local Bricks, Refractory) 1200-1400C 200kg/day • Floated on Tin, Pilkington Process, 2mx4m float tray, made from local brick, covered to protect from dust • Cooled using CO2 in Lehr, 2mx2m, made from local brick. Rollers imported. • Cut into 1m x 1mx5mm glass panels for transport and further cutting. • Located Outdoors 34 Drawing the Glass Fiber Next steps: • Pulling fibers from the melt • drawing them down from 1 mm to 10.0E-6 m, a reduction ratio of 100 • Organosilane coatings are applied to protect the filament surfaces and also to promote better wetting and bonding between the glass filaments and the thermosetting resin during the filament winding process. • taking them up as a single strand on the forming winder or to fiber chopper 35 Filament winding the pressure vessel modules A Filament Winder is like a lathe with a long “cutting arm” that adds material (fiber and resin) instead of removing material The composites filament winding area may have to be ~30 m high to accommodate vertical winding of Homestead modules A large crane is required to support the mass and to maneuver it from vertical to horizontal 36 Chemical Synthesis (example) Aliphatic Organic Synthesis Sequence* * Patent Pending Ag 3a. CH2-CH2 O oxirane CH2=CH2 ethene H2O 3b. HOCH2CH2OH ethylene glycol To ethylbenzene 4. To polyethylene 1. To cumene 6. H2 CO2 + CO 1. MTO CH3OH methanol 2. CH3CH=CH2 propene HOCH2CH=CH2 2-propenol 4a. Cl2 5a. CH2ClCH=CH2 3-chloropropene H2O2 4b. HCl HOCH2CHOHCH2OH HOAc glycerol 4c. Cl2, H2O CaO 5b. As co-reactant for LDPE H2 CH3CH2CH=CH2 + CH3CH=CHCH3 1 and 2-butenes 7a. ClCH2CHOHCH2Cl 6. glycerol dichlorohydrin CH3CH2CH2CH3 butane H2O, H2SO4 Cu CH3CH2CHOHCH3 8a. 8b. 2-butanol As solvent for polyethylene 1. O O=C C=O 7/2O2, 400 - 480oC CH=CH 0.3 - 0.4 Mpa maleic anhydride CH3CH2COCH3 2-butanone, MEK H2S2O8 8c. CaO CH2-CHCH2Cl O epichlorohydrin CH3CH2 CH3 HOOCOOCOOH CH3 CH2CH3 MEKPO dimer CO CH3COOH 9. Acetic acid CO, O2 CH3OCOOCH3 CuCl, 130oC, 2000kPa Dimethyl Carbonate 37 Chemical Synthesis (example) Polyethylene Part Manufacture • Polyethylene can be synthesized in three steps: (1) methane to (2) ethylene to (3) polyethylene pellets or flake. • As a thermoplastic it can be remelted and re-extruded as sheet, piping, bottles. Extrusion machines and dies are complex and will need to be imported from Earth initially. • PE is limited to use at low temperatures due to creep/viscoelastic deformation. • It is chemically resistant to the point of being difficult to bond to other parts except by welding or by mechanical joining. Extrusion product lines are compact 38 O2 42.5% Si 20% Fe 15% Mg 5% Al 5% Ca 4% Na 3% S 2% P 1% Cl 0.8% K 0.6% Ti 0.6% Mn 0.3% Cr 0.2% ORE BENEFICIATION Sand for Mortar 2000kg per batch* Front End Loader To Gravel Storage and Land Fill To Al To Lime Refining Refining Sand Sand washing process shares time with ore washing. Elect (200KWh each batch, 140KWel for 16hr ops) HCl* H2 Prod/Stor (~33kg) Cl2 NaOH & NaCl from KOH Crusher Prod/Stor To Al 3m2 footprint Al & Lime Water (~75kg) Refining and 2m high. Recycle (Part recovery Class/Dryer of Na & K, Magnetic 8m3. Si ~2% of ore) Separation 2000kg ore (4000kg dry per (~400kg) 46degC batch each hour) Pneumatic Crusher & misc Hydraulic Dryer + CaXX Separation (6-30mm Mass 2000kg (60min size) Classification Fines batch time) Pressure Iron (~10uM) Fines Lock Condenser (~300kg Fe) Fines <6mm + misc Water HWH To Brick & Ceramic Refining Separation 270KWth 130KWth Tank Notes: 2000kg 1. Assume 5% of raw ore mass moisture. Makeup Auto Sand for 2. Excavation area ~7500m2. ~0 gallons Strainer To Iron & Mortar *24 sand/ore batches/day @4000kg each of Water Steel Refining Mixing Backwash required through Classification for Cl for HCl. Raw Ore Graphic by Mark Homnick. Copyright © 39 Requirements • Steel Processing 400kg/day 1500K • Aluminum Processing 25kg/day 1000K • Glass Processing 200kg/day 1200K1400K • Manufactured Products as needed for construction(i.e. Structural, wire,…) • Dual use or Flexible equipment used where possible 40 Tubing Mill-Formers • Rolls strips into a tube and welds. • Tubing out can be rolled or cut in lengths. 41 Overview of Nuclear Reactor Design • Concept developed by MIT Nuclear Engineering Dept. (Presented at Mars Society Convention 2004) • 400kWe, 2MWth • 25 year EFPL (Effective Full Power Lifetime) • CO2 coolant, insensitive to leaks or ingress • Shielded by Martian soil, rocks and water • Hexagonal block type core (slow thermal transients, large thermal inertia) • Epithermal spectrum Control Drums • Dimensions L=160cm, D=40cm • Mass 3800 kg • Fuel 20% enriched UO2 dispersed in BeO • 20% efficient Brayton cycle energy conversion, both open and closed cycles possible. Fuel Pins 42 MRM Electrical Energy Demand Load HandledbyDivision SpaceCategory (ieOwner) (WhereLoadIs) Dryer/Pump Crusher Front EndLoader NAOH/HCL Dryer / PumpUnits Grinder Kiln All Elements- Steel Dryer / Pump Brickmaking Brick/ CeramicFurnace GlassFurnace Dryers/ Pumps Grinding RemainingProcesses Mining/ RefiningTF Mining/ RefiningTF Mining/ RefiningTF Mining/ RefiningTF Mining/ RefiningTF Mining/ RefiningTF Mining/ RefiningTF Mining/ RefiningTF Mining/ RefiningTF Mining/ RefiningTF Mining/ RefiningTF Mining/ RefiningTF Mining/ RefiningTF Mining/ RefiningTF Mining/ RefiningTF Refining Refining Refining Refining Refining Refining Refining Refining Refining Refining Refining Refining Refining Refining Refining All Elements Mining/ RefiningTF Refining All Elements(SWAG) Mining/ RefiningTF Refining All Elements(SWAG) Mining/ RefiningTF Refining All Elements(SWAG) ManufacturingTF Manufacturing All Elements(SWAG) ManufacturingTF Manufacturing All Elements(SWAG) ManufacturingTF Manufacturing SpaceDescription (WhereLoadIs) OreBeneficiation OreBeneficiation OreBeneficiation OreBeneficiation LimeRefining LimeRefining LimeRefining Steel Refining Glass/ Brick/ Ceramic Glass/ Brick/ Ceramic Glass/ Brick/ Ceramic Glass/ Brick/ Ceramic AluminumRefining AluminumRefining AluminumRefining AlternateWater Evaporator Plastics/ Polymers Refining Fiberglass(Resin) BambooManufacturing Equip MetalsManufacturing Equipment PlasticsManufacturing Equipment EquiMax Utili- valent Power zation Continou ConCyclic? Facto sLoad sumption r Value [kW] [kW] 1.00 No 1.00 1.0 5.00 Yes 0.33 1.7 0.00 Yes 0.00 0.0 140.00 Yes 0.67 93.8 1.00 Yes 0.33 0.3 2.00 Yes 0.33 0.7 0.00 Yes 0.00 0.0 0.00 Yes 0.00 0.0 1.00 Yes 0.33 0.3 2.00 Yes 0.33 0.7 0.00 Yes 0.00 0.0 0.00 Yes 0.00 0.0 2.00 Yes 0.33 0.7 2.00 Yes 0.33 0.7 160.00 Yes 0.33 52.8 1.00 No 1.00 1.0 171.30 Yes 0.33 56.5 171.30 Yes 0.33 56.5 10.00 Yes 0.33 3.3 20.00 Yes 0.33 6.6 20.00 Yes 0.33 6.6 43 E q u i v a l e n t C o n t i n o u s P o w e r L o a d :2 8 3 . 1 MRM Thermal Energy Demand Prim aryCoolant Loads(IEHighQ ualityHeat 1100degC) Loadsareduringoperation(ie8hoursduringtheday, eachday). Load SpaceCategory SpaceDescription M axPower [kW th] Dryer / Pum p-OreBen Exterior Areas OreBeneficiationArea 485 Dryer / Pum pUnits-Lim e Exterior Areas Lim eRefiningArea 220 Kiln-Lim e Exterior Areas Lim eRefiningArea 250 All Elem ents-Steel Exterior Areas Steel RefiningArea 200 Dryer / Pum p-Brick Exterior Areas Glass, Brick, Ceram icArea 270 Brick/ Ceram icFurnace Exterior Areas Glass, Brick, Ceram icArea 400 Dryer / Pum ps-Alum Exterior Areas Alum inumRefiningArea 220 Rem ainingProcesses-Alum Exterior Areas Alum inumRefiningArea 280 PlasticsRefining M anufacturing M anufacturing-M aterials1 20 FiberglassResinProduction M anufacturing M anufacturing-M aterials1 6 Daytim eLoad(for 8hours): 2,351 kW thHighQHeat 44 Energy Distribution Grid 45 Typical Round Trip Mission Plan (NASA Design Reference Mission (DRM) Hab & Crew Ascent+Fuel+Power Earth Return 3 Crews of 6 = 18 people, 1.5 years on surface, 3 + 3 + 3 + 1 spare = 10 craft, + 10 fuel = 20 heavy launches 46 Mars Homestead Plan Do Not sent (most) return craft / Do send refining & manufacturing Hab & Crew Extra Manuf. Equip. Ascent+Fuel+Power Earth Return Result: for the same 250 T of payload, we get a Permanent Base for 12 ( … 24, 36, 48 …) Same launch cost as 3 Round Trips for 3 x 6 = 18 people47 Prototype Projects Small projects suitable for local groups, students, university classes. Design or select equipment for: • Furniture Manufacture • Kitchen equipment • Inflatable structures • Masonry structure (foam?) • Table top process demos • Miniature plastics moulding • Miniature machine shop • equipment • Recycle spacecraft hardware Greenhouse Experiments • Clothing from parachutes •Portable power supplies • Felt & paper manufacture • Mars Cookbook • Metal Refining \ \ \ AAA / / / • Surface Vehicles < Explosives > • Robotic assistants / / / VVV\ \ \ \ • Flexible chemical equipment • Gas separation equipment • Fiberglass winding • Brick laying robots Outfit a Single Module Small Robot Projects 48 Conclusion of Hillside Base description Presented by: Bruce Mackenzie Bruce@MarsHome.org (781)944-7027 Graphic by Georgi Petrov. Copyright © 49 ™ Project ™ The Mars Homestead A Project of the non-profit Mars FoundationTM Info@MarsHome.org www.MarsHome.org Bruce Mackenzie April Andreas – Mars Cookbook James Burk – Webmaster Frank Crossman – Polymers & Glass Robert Dyck – Refining, Space Suits Damon Ellender – Metals, Gas Plant Gary Fisher – Waste Treatment Mark Homnick - Mgr Inka Hublitz – Agriculture William Johns, MD - Psychology K. Manjunatha – IT / IC / Comm Joe Palaia – Electrical, Nuclear Georgi Petrov - Architecture Richard Sylvan, MD. - Medical You could live here! Help us make it happen! Graphic by Georgi Petrov. Copyright © 2005 Mars Foundation. 50 Mars Homestead Future Directions Presented by: Bruce Mackenzie Bruce@MarsHome.org (781)944-7027 And Frank Crossman Damon Ellender Gary Fisher Georgi Petrov Graphic by Georgi Petrov. Copyright © 51 Next Steps for Mars Foundation Mars Homestead project: • Mars Settlement Reference Plan • Refine Design / Hillside / Any Site As Available: •Safe Haven / Passive Thermal Control •Novel Technologies •Contests •Prototype Projects, ie, Brick / Agriculture / fiberglass •Economize Staging Sequence •Design Mockup “Mars Homestead” •TBD – Major Project •Triple Launch •Demo Site for Contests/Technologies •Economic models, finance Settlement •Fun Designs: •Children, Hands-On / Museum •Outlying “Mars Homesteads” •Truck Stop / Pony Express •City design •Internship, admin help, editor, webmaster, graphic artist 52 Mars Settlement Reference Plan ™ •Chapter format on web, and •Optional book format •Document current work (Hillside Base 1) •Continue to later work 53 Future Directions Refine / Economize Deployment: • Not Site Specific, no hillside required •Start with fewer construction materials to delay transportation costs: perhaps fiberglass, ceramics, sintered regolith (brick) • Add additional construction materials as base develops: Plastics, steel aluminum, pressboard, paper •Use for non-life critical construction, only, at first Greenhouse tanks, trays, Interior partitions, furnishings Trailers, •Construct Habitat pressure shells, later 54 Future Directions Safe Haven / Passive Thermal Control -Greenhouse Outside Modules -Radiation Shielding -Kitchen & Workshops Inner Modules -Side Lit with Mirrors -Emergency Living Quarters -Convective Cooled -Low Power in Emergency -Curtains to Retain Heat 55 Safe Haven / Passive Thermal Control 56 Private Suites More detailed design of the private suites. • Currently the plans and 3D don't quite match up. They need to be • studied in more detailed to make sure that we have a viable design. • I'm attaching a couple of images that you can use for your slides. • Cheers • Georgi 57 Future Directions Novel Technologies Investigate new technologies, or ones not cost effective on Earth Example: Iron Carbonyl Process: - Use CO to extract Iron, high pressure liquid, ~ 200 ° C -Deposit directly into a mold to leave solid Iron (James B.) 58 Future Directions Contests - Proposal to refine specific materials with COTS equipment Brick, Fiberglass , Polyethylene, Al, - Breadboard to make specific materials - Demo minimal mass of equipment needed - Demo increasing strength of finished material - Construct a finished object given X kg of equipment, make a pressurized pipe NASA Centenial Challenge, administer (Gary F.) 59 Prototype Projects Small projects suitable for local groups, students, university classes. Design or select equipment for: • Furniture Manufacture • Kitchen equipment • Inflatable structures • Masonry structure (foam?) • Table top process demos • Miniature plastics moulding • Miniature machine shop • equipment • Recycle spacecraft hardware Greenhouse Experiments • Clothing from parachutes •Portable power supplies • Felt & paper manufacture • Mars Cookbook • Metal Refining \ \ \ AAA / / / • Surface Vehicles < Explosives > • Robotic assistants / / / VVV\ \ \ \ • Flexible chemical equipment • Gas separation equipment • Fiberglass winding • Brick laying robots Outfit a Single Module Small Robot Projects 60 Manufacture of Brick Barrel Vaults •-Use of Robotics to manufacture brick barrel vaults •Assumptions •Possible Methods •Basic Design •Kinematic Design •Work Flow Analysis •Recommendation Agricultural Concepts •research for construction methods, •crop selection, crop efficiencies, •facility management systems. •Insulated and Temp Controlled •Solar and Opaque Greenhouses •Complete Mass balance and Energy Balance Calcs •Crop Efficiency versus Ph 1 programming estimates •Modular to allow for concurrent experimentation Dar al Islam school, Abiquiú, New Mexico 61 Funding / In Kind Support Large and small Contact us to help 62 Triple Launch •Send 3 Crews, •To improve chance of success, •Lessen chance of program abandoment (Gary) Case for Mars 2, conference workshop, Drawn by Carter Emmart 63 Outlying Mars Homesteads First Settlement grows to be “Manufacturing Center” New Arrivals land at spaceport (St. Louis) Outfit yourself with Supplies &Rover (Conestoga Wagon) Travel to site of your new home/farm/mine/outpost, Set up home and tools of your trade. Pony Express Routes Establish travel routes on Mars between settlements, Set up ‘truck stops’ (wayside lodges) along the route, Travelers stop for meals, stretching, lodging, provided by Inn keeper and family. Frequent emergency shelters, double as automated farms 64 Future Directions Economics: large-scale commercial settlement Business model of full settlement of the Red Planet. Passenger tickets paid in Earth dollars, spacecraft maintained by Mars, fuel from in-space resources. This provides profit to Earth investors without bringing a physical product back. -a fully reusable Earth-orbit-to-Mars-orbit transport - ship, the size of an ocean passenger ship - permanent Mars shuttle; Mars surface to Mars orbit and back - an Earth shuttle: surface to LEO, the only part paid by Earth money -city on Mars to receive new arrivals, and - provide equipment and provisions for new settlers. -A "company town" built by the same corporation that operates the ship, and populated mostly by it's employees. (Rob D.) 65 Full-Scale Mars Prototype/Research Center: • A research facility studying future permanent Mars Settlement. • Publicly demonstrates the feasibility and advantages of living beyond the Earth. Goals: 1. Research feasibility of early, low-cost, permanent settlement of space (starting with Mars). 2. Publicity, Education, Public Involvement; especially children. Uses: • A site to integrate research equipment. • Research on processing food with minimal equipment • Research on building techniques, using local Martian materials • Research on (semi-closed) biological life support, • Open to the Public • Contests (rover run-offs, construction, etc.) • School tours, special programs, children's camp, private events • 'Living History' community (Plymouth, Sturbridge) • Apply lessons learned to Earth ecology. 66 M a r s R e s e a r c h & O u tr e a c h C e n te r , 'V a lle y' la yo u t 7 / 6 / 2 0 0 5 , -B ru c e M a c k e n z ie , V e rs io n 1 Bus S top E ntrance/ H is t o r ic a l M a in R oad N AS A D R M ( D e s ig n R e f. M is s io n ) t o P a r k in g Mars H om estead(tm ) O u t fit t in g S h o p ( G ift S h o p ) / E x it C u r r e n t D is p la y / C o n t e s t / & /o r R over Area G a s P la n t / R e fin in g / M a n u fa c t u r in g S p e c ia l E v e n t s P a v illio n ( o p e n fo r e x p a n s io n ) V a lle y F lo o r V ie w in g T e r r a c e S u r r o u n d in g H ills / C r a te r R im C urrent R esearch/ S p e c ia l E x h ib it s ( o p e n fo r e x p a n s io n ) D R M H a b . (t u n a ) D R M R e t u rn V e h . M a s o n ry V a u lt s S e t t le m e n t G a s P la n t / R e fin in g / M a n u fa c t u rin g C u p o la B o u rg h s (? ) C o n d o 's c u t in c liff O b s e rva t io n D o m e , B ig B oP C o n n e c t Tu b e " L a rg e " M o d u le vo n B ra u n S h ip (b u t ve rt ic a l, vis ib le fro m h ig h w a y ) G re e n h o u s e , 1 s t E x p e rim e n t a l Jo e 's " B o o m " 3 m , Te rra c e L e ve l G re e n h o u s e , p ro d u c t io n S e t t le r O u t fit t e r (G ift s h o p ) (t h e c o lo r of m oney ) 0 m , L o w e s t L e ve l o f M a rs Te rra in In fla t a b le P a villio n (S p e c ia l E ve n t s ) a d d fro m h ttp :// re se a rc h p a rk.ksc .n a sa .g o v /i m a g e s/ si te l o c a ti o n 1 -l g .j p g ksc -si te l o c a ti o n 1 -l g .j p g 6 m , C ra t e r R im 9 + m , O b s e rva t io n H ill b y B ru c e M a c k e n z ie (c ) 2 0 0 5 , M a rs F o u n d a t io n 67 Future Directions (for FUN ! ) City Design (Bill M.) 68 Mars Homestead project of the Mars Foundation, Hillside Base pictured Presented by: Bruce Mackenzie Bruce@MarsHome.org (781)944-7027 Join Us Graphic by Georgi Petrov. Copyright © 69