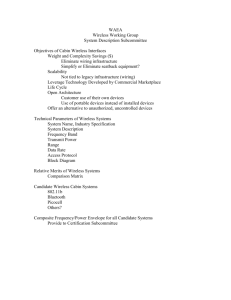

Wireless IEC62591 Customer Presentation

advertisement

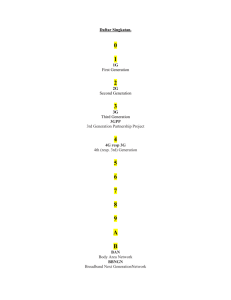

Remote Automation Solutions IEC62591 Wireless Interface Business Challenges Reliability & Access Efficiency & Throughput Financial Results CRITICAL BUSINESS CHALLENGES Personnel & Resources Safety & Environment Key Customer Stakeholders Asset Manager Reduced Profitability High operating cost, low yield Oil & Gas Industry Business Challenges by Functions Operations/SCADA Manager Rising Operating, Maintenance & Compliance Costs Production Manager Decreasing Productivity Difficulty optimizing production HSE Managers Rising Risks Detecting Safety & Environment problems Field Technicians/Engineers Rising Workload Costly frequent trips to remote sites Business & Operational Challenges Facing Oil & Gas Producers High trenching, wiring, labor and Installation Getting Online Faster Cost make automating prohibitive for at least 20% low point remote sites “Per day production delay on a 50K bbl’s/day facility causes $2M revenue and opportunity loss” Shortage of Trained Workforce “Shortage of O&G workforce will lead to critical impact on business” New Oil / Gas Field Constructions (CAPEX) Smart Wireless Vision Adopted at Over 3000 Customer Sites Globally Emerson’s Wireless Experience update: • ~8000 wireless Networks in operation • Over 3000 SmartWireless installations • ~100,000 wireless process devices installed • ~950 million operating hours Offshore Installations Land Installations IEC62591 Wireless Interface For Flow Computers and RTUs Wellhead Customer Solution Value Drivers Challenge Smart Wireless Field Link Time to first oil drives investment decisions 60% faster installation and commissioning. Declining Production rates for unconventional wells 30% or more installed cost savings over wired alternatives Operating and field maintenance cost inflation impacts margins Most robust diagnostics eliminate false reading leading to bad operational and maintenance decisions. Need common standards that provide future architectural flexibility thru production development spectrum Platform harmonization with tightest product integration from Emerson 6 Proprietary & Confidential FloBoss ControlWave New Interface Modules ROC IEC62591 Wireless Interface For Flow Computers and RTUs Midstream CustomerSolution Value Drivers Challenge Time to first product delivery drives investment decisions Difficulty adding additional measurement points Operating and field maintenance cost inflation impacts margins Need common standards that provide future architectural flexibility when replacing legacy station controls Smart Wireless Field Link FloBoss 60% faster installation and commissioning. 30% or more installed cost savings over wired alternatives Most robust diagnostics eliminate false reading leading to bad operational and maintenance decisions. Platform harmonization with tightest product integration from Emerson 7 Proprietary & Confidential ControlWave New Interface Modules ROC IEC 62591 (WirelessHART) Global Standard Global Standard An IEC standard-IEC 62591 (unanimously approved March 26, 2010) • IEC 62591 is WirelessHART • HART 7 protocol • Adopted March 26, 2010 Simple – Reliable - Secure Self-Organizing Network Auto-Recognition of New Devices 99% Field Proven Reliability Self-Healing Network Repairs Itself Finds Alternative Paths Industry Standard 128-bit AES Encryption Unique Encryption Key for Each Message No Site Surveys No Trenching Robust, Multi-tiered, Always-on Security Coexists with other Wireless Networks Robust and Tolerant to all Types of Interference without any Site Survey Data Integrity and Device Authentication Reports Message and Authentication Failures Smart Wireless Portfolio is Large … and Getting Larger Current Portfolio New Products 702 Wireless Leak Detection 702 Discrete 6081C Conductivity Smart Wireless THUM Adapter Smart Wireless Gateway Ovation Native Interface 6081 pH 648 Temperature 848T Multi Input Temperature 9420 Vibration 3051S Series Pressure, Level & Flow DeltaV Native Interface 4300 Series Position Monitor DeltaV S-series Wireless I/O Video Integration with DeltaV Smart Wireless Field Link 2160 Vibrating Fork Liquid Level Switch Traditional Wireless Architecture oPoint-To-Multipoint oPoint-To-Point Process Variable data Level Pressure temperature Easy to install Low cost Generic Modbus Gateway Interface Supports legacy systems Tag ID Device Type Status Alarm RF Failure Low Battery Smart Wireless Gateway Architecture AMS & SCADA Flow Computer Open, easy-to-deploy Secure & Reliable mesh network Automatic re-routing PLC/RTU RTU Process Variable data & full HART Diagnostics Temperature Level Pressure Gateway integrates easily into legacy systems Full access to Advanced HART diagnostics PC, RTU, PLC, FC Extends PlantWeb® Transparent pass-through to AMS Remote Automation Solutions Wireless Architecture Serial, Ethernet or long haul wireless Radio Easy to install Lower cost installation Radio Flow Computer AMS & SCADA PLC/RTU RTU New Secure & Reliable mesh network Automatic re-routing Low power consumption Process Variable data & full HART Diagnostics No Gateway No Modbus mapping Level IEC62591 Standard temperature Pressure Full access to Advanced HART diagnostics ROC, FloBoss & ControlWave IEC 65591 Wireless Technology Only truly integrated RTU/FC wireless solution – One integrated configuration tool – Support built into firmware – Seamless integration from field to back office – No third party gateways – No Modbus mapping High reliability and low power consumption for remote installations – No site survey required – Auto re-routing mesh network – Smaller backup batteries & enclosures Integrated Solution Benefits Distributes measurement & Control to field locations – Not dependent on long haul reliability for data integrity – Local Historical and Alarm logging – Local Control Truly integrated configuration software tools – One software to configure the RTU, flow computer and remote transmitters RTUs & FCs provide local I/O, wired & wireless HART interfaces, interfaces to intelligent devices Data available to SCADA host software IEC62591 Seamless Integration FC, RTU, PLC Platform FB107 ROC800 ControlWave Micro IEC62591 Wireless I/O Module IEC62591 Interface Smart Wireless Field Link IEC62591 Interface IEC62591 Interface ROC800 & FB107 Integration Integrated into ROC800 & FB107 firmware Integrated into ROCLINK configuration software Integrated with OpenEnterprise™ Field Tools Device configurator ControlWave Integration oIntegrated into ControlWave firmware oIntegrated into ControlWave Designer configuration software oIntegrated with OpenEnterprise Field Tools Device configurator Smart Wireless Field Link Smart Wireless Filed Link – 4 wire connection to IEC62591 I/O module – Powered by IEC62591 I/O module No setup or configuration Aluminum or Stainless Steel housing Multiple FM, CSA & IS certifications Antenna selection – Standard range – Extended range Meter selection Smart Wireless Field Link 750 ft (225 m) 2600 ft (800 m) Extended range antenna Wireless Field Devices Field Tools HART Server Wired & WirelessHART Comm Manager Device Configuration Wireless SNAP-ON network analysis and device alerts Field Tools Wired & WirelessHART HART Server Comm Manager HART Modem Use in place of 475 Handheld Field Tools HART Device Configurator Text box makes font hard to read MH R HART is a mark owned by the HART Communication Foundation AMS Wireless SNAP-ON Allows Users to Easily Plan and Manage Field Networks Network Planning – Easily validate / optimize network design against best practices Network Monitoring – Status and communication diagnostics – Alerts Advanced Reporting – Status and communication diagnostics Live Mode Better Understanding the Health of the Device Transmitter status log with time stamp Pressure & temperature sensor log with time stamp - sensor excursions - max/min values Set Maintenance Reminders Custom message & alert time Receive alerts when time expires IEC 62591 Production Applications First only truly integrated WirelessHART Interface for RTUs and Flow Computers Wireless Interface Significant Production Applications WATER INJECTION FLOW STEAM OR GAS INJECTION FLOW INJECTION WELLHEAD MONITORING STEAM INJECTION HEAT EXCHANGER Significant Customer Value – – – – – – – Up to 60% faster installation and commissioning. 30% or more installed cost savings over wired alternatives Easily add unmonitored points Most robust diagnostics eliminate false readings and improves operational and maintenance decisions. Platform harmonization with tightest Emerson integration High reliability wireless data network Low power consumption for remote installations 26 Proprietary & Confidential WirelessHART Wellhead Monitoring Applications WELLHEAD PRESSURE AND TEMPERATURE Indicates health of well and composition of fluids FLOW & NET OIL/WATER MEASUREMENT AT WELL THUM Adapter transmits diagnostics for maintenance use and multiple process variables for monitoring WATER INJECTION FLOW Measures and transmits water flow data and predictive diagnostics WELL ANNULUS PRESSURE Indicates casing pressure – an increase indicates fluid leakage and need to relieve pressure or kill well OIL PRODUCTION VALVE POSITION Monitors open / close status and position of choke valves, manifold valves, and manual valves STEAM OR GAS INJECTION FLOW Measures and transmits steam or gas injection flow data and predictive diagnostics WELLHEAD FLOW Measures temperature for use as an indirect indication of flow OIL PRODUCTION TOTALIZED FLOW Multivariable transmitters efficiently calculate and provide totalized flow output GROSS OIL PRODUCTION Gauge pressure measured at headers is sent to historian to capture production information WELLHEAD FLOW LINE VALVE DIAGNOSTICS Wireless THUM Adapter transmits Predictive diagnostics to aid maintenance STEAM INJECTION HEAT EXCHANGER MANAGEMENT Measures pressure and differential pressure across heat exchangers to monitor performance INJECTION WELLHEAD MONITORING Pressure, temperature and DP flow Measurements provide better visibility of injection process IEC 62591 Transmission Applications First only truly integrated WirelessHART Interface for RTUs and Flow Computers Wireless Interface Significant Transmission Applications REMOTE TANK MONITORING REMOTE PRESSURE MONITORING COMPRESSOR VIBRATION MONITORING STATION PRESSURE & RUN TEMPERATURE Significant Customer Value – – – – – – – Up to 60% faster installation and commissioning. 30% or more installed cost savings over wired alternatives Easily add unmonitored points Most robust diagnostics eliminate false readings and improves operational and maintenance decisions. Platform harmonization with tightest Emerson integration High reliability wireless data network Low power consumption for remote installations WirelessHART General Upstream & Transmission Monitoring Applications FLOW & NET OIL/WATER MEASUREMENT IN TEST SEPARATOR THUM Adapter transmits diagnostics for maintenance and multiple variables for monitoring TEST MANIFOLD & WELL MONITORING Monitoring remote wells producing into a test manifold SEPARATION PROCESS VALVE POSITION Monitors open / closed status and position of manual valves, relief valves, tank inlet and outlet valves, and shutdown valves VIBRATION IN INJECTION PUMPS Monitors vibration of bases and bearings, providing data for predictive maintenance to improve availability SEPARATOR LEVEL MEASUREMENT Monitors separator interface level REMOTE TANK MONITORING Monitoring low pressure points in a distribution system for efficient pressure management reducing leakage PLUGGED FILTER DETECTION Differential Pressure across line filters Indicate maintenance is needed OFFSHORE PLATFORM HEAT DETECTION Remotely monitor heat exchanger’s inlet and outlet temps in harsh, difficult -to-reach areas indicate performance DISTRIBUTION SYSTEM POINT MONITOR Gauge pressure measured at headers is sent to historian to capture production information PIPELINE STATION PRESSURE Monitoring remotely located inlet and outlet pressures WirelessHART Injection Well Monitoring Producer Injector Water/Steam Injection Facility RTU at the pump station, or in strategic field locations RTU logs history, provides long range communications, local display, flow control, logic At Injection wells Line pressure DP across meter Injection pressure Fluid temperature Valve/choke control Use WirelessHART to Gather Required Data for Reporting – Injection Well monitoring • Injection wells are spread out, minimal IO at each point • Information is not time critical • Injection pressures, rates and totals are of high value – Main drivers include governmental regulations and reservoir management needs • RTUs to archive local histories and provide long range communication and data consolidation Test System Manifold Well Testing with WirelessHART RTU/Flow Computer at test manifold At producing wells Test Manifold Producer Automatic Well Testing Valve Control ( Fisher DVC) Measurement (Daniel Orifice, Turbine, MMI) Pressure, Temperatures (Rosemount) Casing, Flow Line Pressures Line pressure Temperatures On/Off status Stuffing Box Leaks WirelessHart Natural Gas Wellhead Well Optimization Plunger Arrival Casing, Tubing, Bradenhead Pressures Valve Position and Control (Future) Testimonials Where successful wireless networks have helped other customers achieve improved performance and financial results Smart Wireless Improves Wellhead Production Allocation Offshore Topsides Wireless Application CHALLENGE Manual collection of key process parameters Conventional methods require high installation and maintenance costs SOLUTION Emerson Smart Wireless – Proven measurement technology – Pressure, Temp, Level, Flow, Discrete – WirelessHART technology RESULTS Decreased CAPEX & Operational Costs Lower Safety risks through online Casing pressure monitoring Production Manager Decreasing Productivity HSE Managers Rising Risks Field Technicians/Engineers Rising Workload Emerson's Smart Wireless Improves Wellhead Monitoring at BP Wytch Farm CHALLENGE – Eliminate manual rounds to monitor wellhead pressure reading – Respond to problems and rectify more quickly SOLUTION – 40 wireless Rosemount® pressure transmitters total • Two transmitters installed per wellhead • A single Smart Wireless gateway, mounted outside process area, connects transmitters to control system • All devices on-line within 30 minutes RESULTS – Improved operations – Automated wellhead pressure monitor – Real time information regarding well performance – Improved maintenance responsiveness to process problems “The wireless instruments have performed without losing any data since they were installed in August …” - Chris Geen, BP Manager Customers Are Solving Real Plant Problems: Chevron San Ardo, Calif. Application: – Pressure transmitters monitor steam injection on out-of-service wells Challenge: Over steaming caused lost production, increased wastewater discharge; field visits required Solution: Smart Wireless network improves personnel safety, increases production, reduces wastewater discharge Application: – Pressure transmitters check down-hole well pressure Challenge: RTU network obsolete, required hard wired power Solution: Battery-powered transmitters collect reliable production strategy data, less maintenance, installed for $60,000 savings “It only took three hours to install all the instruments, configure and establish the network IP address, and make the Ethernet connection to the control room,” Kinne said. “We have eliminated the excess steam usage and now have a reliable steam injection measurement at eight stations.” — Paul Kinne, Chevron head operator Smart Wireless Improves Heat Exchanger performance at EnCana Oil Sands Facility CHALLENGE – Improve efficiency of heat exchangers in energy intensive steam injection process, prevent downtime • Cost-effective way to measure heat transfer in HE’s for boiler feedwater • Predict tube fouling to improve heat transfer and prevent tube rupture SOLUTION – Rosemount® wireless transmitters measure boiler feedwater inlet and outlet temperatures – Wireless network installed and operating in 2 days RESULTS – Improved efficiency of several key heat exchangers – Saved $40,000 versus wired installation – Optimized cleaning schedules to prevent tube ruptures – Boiler fuel consumption reduced “We are now able to maximize heat exchanger operation and maintain the tubes more effectively to prevent heat losses and avoid devastating tube ruptures. We are pleased with the ease of installing the Smart Wireless network, which is working perfectly.” —Stephan Meerman, E&I Supervisor Leveraging HART to Turn Field Insight into Actionable Information 1 Statistical Process Monitoring variable trending •Standard deviation •Coefficient of variation •Mean Uncover opportunities by fingerprinting the process to know what "normal or good" looks like. 2 4 Proactively correct abnormal conditions and improve process performance 3 Decide on accurate alerts for abnormal situation management