Real-Time Simulation for More Electric Aircraft

advertisement

Real-Time Simulation:

Applications to More Electric Aircrafts

Embraer

March 10, 2010

Christian Dufour, Ph.D.

Senior Simulation Specialist, Power Systems and Drives

Lecture Plan

About More Electric Aircraft

Real-Time Simulator Technology update

Onboard Ship Power System example.

Tools for Electric System Simulation

Power Electronic Simulation on RT-LAB

Test Automation and Sequencer

Conclusions

2

About more electric aircrafts

3

Why More Electric Aircrafts?

Efficiency

Bleedless engine design can provide for

energy saving during flight.

Not so obvious: MEA is heavier than

normal plane

4

Classic airplane power distribution (A320)

Propulsion (trust): 20MW

Electrical (200kW)

Pneumatic 1.2MW

Cabin pressurization, Air conditioning, Icing

protection

Hydraulics (240 kW, at peaks)

Avionics, lights, fans, In-flight entertainment

Surface actuation, landing gear operation,

braking, doors

Mechanical

Fuel and oil pump local engine

5

Example of a More Electric Aircraft: Boeing 787

Boeing 787

All onboard systems are electric: APU, Brakes,

Cabin pressurization, Wing ice protection

With 4 primary 230 VAC, 3ph, variable

frequency Generators with 230/115V AC and 28

VDC busses.

Bleedless engines

6

Possible all-DC Bus MEA

Highly redundant configuration

Composed of many power converters

Source: Virginia Polytechnic

7

Real-time simulation basics

8

Real-Time Simulation : Introduction

Free Running Simulation

Faster than real-time

Computation

f(t)

f(tn ) f(tn+1 )

tn-1

tn

Time

tn+1

Time

Slower than real-time

Computation

f(t)

f(tn)

tn-1

f(tn+1)

tn

tn+1

Time

Time

9

Real-Time Simulation : Introduction

Real-Time Simulation

Computation

f(t)

f(tn )

f(tn+1 )

Time

Clock

tn-1

tn

tn+1

Time

DataPosting

Sine equa none conditions for real-time algorithms

Non-iterative

Fixed –step (disqualify Spice-type or Saber simulation

algorithm for example)

IMPORTANT DISTINCTION

In real-time simulation, ALL time step must complete below Ts

Consequently, even if the total calculation time is smaller than

the real time to compute, it may not meet real-time criteria

10

Main Real-Time Simulation Applications: RCP and HIL

Controlled Process: a plant and its controller

Rapid Control Prototyping

Hardware-in-the-Loop

Controller

+

-

Motor

+-

RT-LAB

RT-LAB

RCP: the controller is implemented using a Real-Time Simulator

HIL: the controller is tested with a plant model on a Real-Time Simulator

Evolution of Real-Time Simulator Technology

2009: 1 cabinet, 3 PC with 24 core in total

RT-LAB

32 to 64 cores would be required to

simulate the detailed HQ network

COTS

Sim-On-Chip

Digital COTS

Simulators

1975

30000 square feet Hybrid Simulator

Digital Custom

Simulators

Hybrid (Analog/Digital)

Simulators

Analog

Simulators

Model Based Design

1960

1970

1980

1990

2000

13

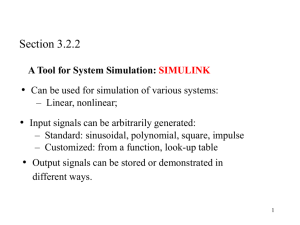

About the Concept of Model-based Design (simplified)

Controller Model

Design

(Simulink Block

Diagram)

Generate

Software from

Model

Correct

Design

Iteratively

Test

Upload Software to

Real-Time Simulation

Platform

14

Example #1: Off-Highway Vehicle (GE-OHV)

Chopper Assembly

Dissipates superfluous energy during breaking

AC Control Group

Controls engine load and power flow

Motorized Wheels

Deliver Traction effort

Alternator

Generates the electrical power

Example #1: Off-Highway Vehicle (GE-OHV)

Actual ECU

I/O

Truck model include:

Dynamics

Inverters

Motors Drives (IM)

Alternator

DC-bus

DC-bus choppers

Etc..

RT-LAB TestDrive (LabView Based Interface)

Example #2: All electric ship

Characteristics:

Highly redundant reconfigurable power system

Composed of many drives including propulsion

Many power converters and switches

Zone 1

Port Bus

Load Group2

on Port Side

NV ac

load

PCM

NV dc

load

PCM

Vital

load

Generator

Group

SW-G1

Load Group1

on Port Side

PCM

Zone 2

Fault Location 2

SW-P1

PCM

NV ac

load

PCM

NV dc

load

EPM

PCM

SW-P3

Load Group 1

on Port Side

Load Group 1

on Port Side

Load Group 1

on Port Side

Load Group 2

on Port Side

Load Group 2

on Port Side

Load Group 2

on Port Side

Generator

Group

Generator

Group

Generator

Group

Load Group 1 on

Starboard Side

Load Group 1 on

Starboard Side

Load Group 1 on

Starboard Side

Load Group 2 on

Starboard Side

Load Group 2 on

Starboard Side

Load Group 2 on

Starboard Side

PCM

PCM

EPM

M

NV dc

load

PCM

PCM

NV dc

load

NV ac

load

PCM

PCM

NV ac

load

SW-G2

Vital

load

Load Group1 on

Starboard Side

SW-P2

Zone 4

M

PGM

Fault

Location 1

Zone 3

Load Group2 on

Starboard Side

SW-S1

SW-S2

SW-S3

Starboard Bus

Yanhui Xie Seenumani, G. Jing Sun Yifei Liu Zhen Li , “A PC-Cluster Based Real-Time Simulator for AllElectric Ship Integrated Power Systems Analysis and Optimization”, Electric Ship Technologies

Symposium, 2007. ESTS '07. IEEE , Arlington, VA., 21-23 May 2007 pp. 396 - 401

17

Test case: ZONE 1 - PORT BUS - DC FAULT

Port Bus

ZONE

Zone 11

Port Bus

Load Group2

on Port Side

NV ac

load

PCM

NV dc

load

PCM

Vital

load

Generator

Group

SW-G1

Load Group1

on Port Side

PCM

ZONE

Zone 2 2

Fault Location 2

SW-P1

PCM

NV ac

load

PCM

NV dc

load

EPM

SW-P2

Zone 4

SW-P3

Load Group 1

on Port Side

Load Group 1

on Port Side

Load Group 1

on Port Side

Load Group 2

on Port Side

Load Group 2

on Port Side

Load Group 2

on Port Side

Generator

Group

Generator

Group

Generator

Group

Load Group 1 on

Starboard Side

Load Group 1 on

Starboard Side

Load Group 1 on

Starboard Side

Load Group 2 on

Starboard Side

Load Group 2 on

Starboard Side

Load Group 2 on

Starboard Side

M

PCM

PGM

Fault

Location 1

Zone 3

PCM

ZONE 1

PCM

EPM

M

NV dc

load

PCM

PCM

NV dc

load

NV ac

load

PCM

PCM

NV ac

load

Load Group1 on

Starboard Side

SW-G2

Vital

load

Load Group2 on

Starboard Side

SW-S1

SW-S2

SW-S3

Starboard Bus

Starboard Bus

Fault applied from t = 0.1s to t = 0.4s

18

All-Electric Ship Real-time Simulation Performance

Ts = 50 μs

Target 1

Target 2

CPU2

CPU3

CPU1

CPU2

CPU3

Zone 1

Load

Group 1

Zone 1

Generator

Group

Zone 1

Load

Group 2

Zone 3

Load

Group 1

Zone 3

Generator

Group

Zone 3

Load

Group 2

Shared Memory

Zone 2

Load

Group 1

Zone 2

Generator

Group

Zone 2

Load

Group 2

CPU4

CPU5

CPU6

PCI Express

CPU1

Shared Memory

Zone 4

Load

Group 1

Zone 4

Generator

Group

Zone 4

Load

Group 2

CPU4

CPU5

CPU6

Test 1:

Test 2:

2 Zone AES

1 eMEGAsim target

6 (of 8) processor cores used

Minimum achievable Ts = 32 μs

4 Zone AES

2 eMEGAsim targets

Dolphin PCI-SCI comm. link

12 (of 16) processor cores used

Minimum achievable Ts = 33 μs

19

Components of a real-time simulator

Real-time simulator components

Sequencer

Applications

Models

Solvers

Inputs/Outputs

Real-Time Platform

Communication

Processing

20

RT-LAB solutions for power systems

OPAL-RT provides various tools for the simulation of

power systems, motor drives and power electronic

converter are provided

Simulink

MATLAB

Simulink

RTeDRIVE

Sequencer

SimPowerSystems

ARTEMiS

ARTEMiS: Real-time enabler for SimPowerSystems

RTeDRIVE: Power Electronics and motor drives toolbox

21

Opal-RT Toolboxes for electric system simulation

ARTEMiS

Plug-in to SimPowerSystems

Makes pre-computation of circuit modes to

allow real-time performance

Increase stability and precision

22

Opal-RT Toolboxes for electric system simulation

RTeDRIVE

A specialized library of IGBT/GTO/MOSFET

inverters/choppers (2- and 3-level)

Use interpolated switching functions

Compatible with SPS or Simulink only

23

RT-LAB features

24

RT-LAB eMEGAsim Simulator Hardware Architecture

Host/Target Architecture

Simulink

Model

Single-,

Dual-, or

Quad-Core

CPU

PCI EXPRESS

Windows

QNX & RT-Linux RTOS

SIMULINK/RTW based

Multi-core support

Simulink

Model

Sh.Mem.

CPU

PCI

HILBox PC1

25

RT-LAB eMEGAsim Simulator Hardware Architecture

Host/Target Architecture

Windows

QNX & RT-Linux RTOS

SIMULINK/RTW based

Multi-core Processors

Shared-Memory

Multi-CPU board

Simulink

Model

Single-,

Dual-, or

Quad-Core

User has the possibility

to add PCI cards to the

simulator with standard

Protocol like TCP/IP,

UDP/IP, RS-232

Or to develop and study

advanced protocols (ex:

IEC-6185)

PCI

PCI PCIe Extension

CPU

PCI EXPRESS

Simulink

Model

Sh.Mem.

CPU

RS-232, CAN, TCP/IP

IEC61850, LoadRunner

HILBox PC1

26

RT-LAB eMEGAsim Simulator Hardware Architecture

Host/Target Architecture

Windows

QNX & RT-Linux RTOS

SIMULINK/RTW based

Multi-core processors

Digital IO requirements

For power Electronics

Must be capable of

sampling Thyristor/

IGBT/GTO/MOSFET

gate with great accuracy

The latency must also

be very low so it does

not to slow down the

simulation (PCI Express)

CPU

16 DO

Sh.Mem.

CPU

PCI Express

FPGA (op5142)

Shared-Memory

Multi-CPU board

PCI EXPRESS

Carrier (op5210)

16 AO

16 AI

Carrier w (op511x)

16 AO

16 AI

Carrier w (op511x)

16 DO

FastCom

16 DI

16 DI

Carrier (op5210)

HILBox PC1

27

Sampling of fast PWM gate signals

For this purpose, PWM

pulse are captured on

the FPGA card by

100MHz counters

Normalized ratio (Time

stamp) is send to the

inverter models on the

CPU

The model on the CPU

use the Time Stamps to

compute interpolated

voltages

28

Effect of switch gate sampling and interpolation

RTeDRIVE inverter model use the time stamps to

produce very accurate results

Example: a simple DC chopper (PWM=10kHz, Ts=10µs)

Bad sampling (like if we use regular SPS) causes

important non-linearity in the input-output characteristic

But very linear caracteristic with RTeDrive TSB inverters

SimPowerSystems

EMTP, PLECS

TSB

Tcarrier/Ts=10

Effect of switch gate sampling and interpolation

Precise enough to take into account

deadtime effect smaller that the

sample Time

Below is the effect of dead time increment

of 2 µs (with a sample time of 10µs!)

Hardware Architecture (FPGA models)

Host/Target Architecture

Windows

QNX & RT-Linux RTOS

SIMULINK/RTW based

Xilinx System

Generator Blockset

CPU Model

Multi-core processors

FPGA user programmability

Sh.Mem.

for advanced model design

The FPGA card can be programmed by

the user using Xilinx System Generator CPU

No VHDL language skill required.

PCI Express

It is a Simulink

blockset

FastCom

PCI EXPRESS

Shared-Memory, Multi-CPU board

Models with 10

ns sample rate

can be coded on

this card!

16 DO

FPGA (op5142)

16 DI

Carrier (op5210)

16 AO

16 AI

Carrier w (op511x)

16 AO

16 AI

Carrier w (op511x)

16 DO

16 DI

Xilinx SG model

Carrier (op5210)

HILBox PC1

31

Simulator Hardware Architecture (Expandability)

Host/Target Architecture

Windows

QNX & RT-Linux RTOS

SIMULINK/RTW based

Multi-core processors

Shared-Memory

Multi-CPU board

CPU

Expandability

FireWire

INFINIBAND switch

DOLPHIN SCI /PCIe

(2 to 5 us latency)

CPU

PCI Express

PCI

PCI EXPRESS

16 DO

Sh.Mem.

Dolphin

FPGA (op5142)

16 DI

Carrier (op5210)

16 AO

16 AI

Carrier w (op511x)

16 AO

16 AI

Carrier w (op511x)

16 DO

16 DI

Carrier (op5210)

HILBox PC1

Dolphin

HILBox PC2

32

About the necessity for testing

Real-Time Solvers for Power Systems

33

Simulation solvers for power systems

Key characteristics of power systems

Contains a wide range of frequency modes

Requires ‘stiff’ fixed-step solvers. Stiff solver remains

stable even with mode above the simulation Nyquist

limit.

Contains a lot of PWM-driven power electronics

The simulator must avoid sampling effect when

computing IGBT pulse ‘events’ internally or when

reading PWM pulses from its I/Os

34

Stiff solvers methods for power system simulation

Simulation methods electric systems:

State-Space (SimPowerSystems)

Switching-function (Power Electronics &

converters)

FPGA-based methods

Stiff solvers methods for power system simulation

State-Space approach of SimPowerSystems

We can also find the exact state-space solution

x Ak x Bk u

y Ck x Dk u

With k, matrix set index for switch permutations

This can be discretized with the trapezoidal method like

in SimPowerSystems for Simulink

Trapezoidal method: order 2.

It can also be discretized by higher order methods

Higher order methods (order 5) implemented in

ARTEMiS, a solver package of eMEGAsim.

Stiff solvers methods for power system simulation

State-Space approach

Continuous time state-space expression x Ak x Bk u

Solution for time step T:

xn1 e

AT

t

xn

t T

e A( t ) Bu ( )d

How to compute the ‘matrix exponential’ eAT ?

I AT / 2

e

I AT / 2

ARTEMiS art5 method (order 5)

2

2

1

I

AT

(

AT

)

5

20

e AT

2

3

3

3

1

I 5 AT 20 ( AT ) 60 ( AT )

Trapezoidal method (order 2)

TALYOR

EXPENSION

e

AT

AT

AT AT 2 AT 3 AT 4 AT 5

AT n

I

...

...

1!

2!

3!

4!

5!

n!

Effect of higher order discretization

Simple case of RLC circuit energization

Artemis ART5 solver

more precise than

Trapezoidal solver at

100 us

Numerical stability issues

Discretized systems is not guarantied to be stable

It depends on how Laplace poles are ‘mapped’ in the z

domain. Ex: Forward Euler has poor stability

A-stability (Stiff stability) (ex: trapeze method) guaranty

discrete stability (for linear systems)

Laplace pole (s) mapping

Im{l}

Trapeze

Stability Region

-2/T

Forward Euler

Stability Region

RLC network Euler

T=0.01µs

Trapeze

T=100µs

y’=ly

Re{l}

Numerical stability issues with trapezoidal integration

Even if it is stable, the

trapezoidal rule (tustin) is

prone to numerical oscillations

The z-domain mapping is stable

but oscillatory for high

frequency Laplace poles

Numerical stability issues with trapezoidal integration

A-stable methods can be highly oscillatory

How are mapped high frequency poles?

It depends on the ‘stability function’ again

ARTEMiS art5 (L-stable)

Trapeze (A-stable)

2

2

1

I

AT

(

AT

)

I AT / 2

5

20

lim AT

0

lim AT

1

2

3

3

3

1

I 5 AT 20 ( AT ) 60 ( AT )

I AT / 2

Laplace map

Im{l}

y’=ly

Z- domain map

Im{z}

y(n+1)=zy(n)

Re{l}

Re{z}

-1

z mapping near -1

means oscillations

RTeDRIVE approach: interpolated switching function

Switching function approach

A special solver method for power electronic system

using high-frequency PWM.

It is a ‘simple’ controlled voltage source!

Interpolation methods are used to obtain high accuracy

in the Opal-RT RTeDRIVE package

High impedance mode supported now.

~100V

V_load

~0

V_load

1

gate

0

*

*

Gup

*

Glow

* V_load near zero for positive I_load by lower anti-parallel diode action if both GIBT are turned off

Effect of switch gate sampling and interpolation

RTeDRIVE inverter model use the time stamps to

produce very accurate results

Example: a simple DC chopper (PWM=10kHz, Ts=10µs)

Bad sampling (like if we use regular SPS) causes

important non-linearity in the input-output characteristic

But very linear caracteristic with RTeDrive TSB inverters

SimPowerSystems

EMTP, PLECS

TSB

Tcarrier/Ts=10

Effect of switch gate sampling and interpolation

Precise enough to take into account

deadtime effect smaller that the

sample Time

Below is the effect of dead time increment

of 2 µs (with a sample time of 10µs!)

Interpolated switching functions: example case 1

Motor Current [A]

Japan, 2004

ARTEMiS used for rectifier side

RTeDRIVE used for inverter

HIL Simulation

20

10

0

PWM

2.25kHz

-10

-20

0

0.003

0.006

0.009

Physical System

20

Motor Current [A]

Mitsubishi Electric Co

0.012

10

0

-10

-20

0

0.003

CPU 1: (Ts= 80 us)

CPU 2: (Ts= 10 us)

© Opal-RT © Opal-RT

x6

S

x6

(Fpwm =9 kHz)

IGBT

pulses

Currents

Quadrature

encoder signals

10

0

PWM

4.5kHz

-10

-20

External controller (sampling rate =55 s)

Motor Current [A]

N

0

0.003

0.006

0.009

0.012

MITSUBISHI

0

-10

-20

0

0.003

0.006

0.009

0.012

0.009

0.012

Time [sec]

20

Motor Current [A]

0.012

10

Time [sec]

20

10

0

PWM

9kHz

-10

-20

0.009

20

20

Motor Current [A]

PWM

inverter

permanent

magnet motor Tload

Motor Current [A]

3-phase

diode

source

rectifier

reactor

0.006

Time [sec]

Time [sec]

0

0.003

0.006

Time [sec]

0.009

0.012

10

0

-10

-20

0

0.003

0.006

Time [sec]

45

Example 2 – Industrial Motor Drives

Multi Level Inverter Drive

CONVERTEAM-ALSTOM

(France)

RT-LAB Electric Drive Simulator

12-PULSE

RECTIFIER

3-LEVEL NEUTRAL CLAMPED

BRIDGE

dV/dt

FILTER

HV

NETWORK

INDUCTION MOTOR

12MW-6600V

M

~

3~

PEC CONTROLLER

~

PRECHARGE

LV NETWORK

line voltage wave form

1200V

This Controller is connected

Externally to the Simulator

46

Example 3 – Industrial Motor Drives

Multi Level Inverter Drive

CONVERTEAM-ALSTOM (France)

12-PULSE

RECTIFIER

3-LEVEL NEUTRAL CLAMPED

BRIDGE

dV/dt

FILTER

HV

NETWORK

INDUCTION MOTOR

12MW-6600V

M

~

3~

PEC CONTROLLER

~

PRECHARGE

LV NETWORK

Pulse shutdown modeled

with the help of Converteam

Required the design of an

hybrid switching-function

with high-impedance

capability

Results of Hardware-In-the-Loop Tests

Motor Acceleration

Emergency Pulse shutdown

47

Importance of Interpolation (again)

Interpolation is important because the Real-Time Simulator

is a sampled system

The above figure shows the typical effect of neglecting

‘interpolation’ during the simulation.

EM Torque

5

2

DEAD-TIME

Torque in N.m

1

0

-1

-2

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

1.4

1.6

1.8

2

Currents

Inverter Currents

1500

1000

Current in A

Converteam case

Ts=40us

Deadtime=20us

Fpwm=400Hz

Interpolation disabled

@ 1 second

Electromagnetic Torque

x 10

500

0

-500

-1000

-1500

0

0.2

0.4

0.6

0.8

1

Time in s

1.2

WITH INTERPOLATION

WITHOUT INTERPOLATION

C. Bordas, C. Dufour, O. Rudloff, “A 3-Level Neutral-Clamped Inverter Model with Natural Switching Mode

Support for the Real-Time Simulation of Variable Speed Drives”, Proceedings of the 8th International

Symposium on Advanced Electromechanical Motion Systems (ELECTROMOTION-2009), Lille, France, July

1-3, 2009

Interpolated switching functions: how high can you get?

3-level STATCOM with 72 IGBT (Mitsubishi Electric)

20 µs, 3 CPU with the controller

1000 time faster than conventional

simulation software

Actual diode/IGBT count: 10*6*3=180

Reference model

In EMTP/RV (3us)

vs Simulink/SPS/ RT-LAB (50 us)

IPST 2009, Kyoto - Japan

49

Simulation On Chip (FPGA)

RT-LAB XSG permits to use Xilinx System Generator

models inside RT-LAB frame work

Enables complex model to run on the FPGA of RT-LAB

Examples:

PMSM motor

IGBT inverter,

PWM modulator

Power electronics

Simulation On Chip (FPGA)

No need to know VHDL language

But you need to know fixed-point arithmetic

Real-life example: Rotary Variable Differential

Transformer (RVDT) designed for Embraer in

one week using XSG!

A typical XSG model in RT-LAB

Simulation On Chip (FPGA) Example: PMSM Drive

PMSM drive built on FPGA using only XSG

PMSM, BLDC and FEA-Based PMSM

Include: test modulator, quad enc., resolver

External Digital Inputs

Internal PWM test source

internal 3-phase

voltage source

Analog Outputs

IGBT inverter

iabc

modulator

upper IGBT

pulses

N

S

lower IGBT

pulses

Fmod :10-200 kHz

Permanent

magnet motor

[ L]1 (Vabc

d abc

RI abc )dt I abc

dt

shift

Dead time

Modulation index

IGBT gate source selection

Phase shift of Vsource rotor & Vsource

*C. Dufour et al. “Real-Time Simulation of Finite-Element Analysis Permanent Magnet Synchronous Machine Drives

on a FPGA card”, Proceedings of 2007 European Conference on Power Electronics and Applications (EPE-07) ,

Aalborg, Danemark , Sept 2007

Test sequencer

Test sequencer

53

Test sequencer: a key part of real-time simulator

Test sequencer

requirement

Capability to launch test

automatically

Capability to record and

analyze data

Capability to manage

models

Use the full power of

MATLAB and Python

languages

54

Test sequencer: a key part of real-time simulator

Usage case: Monte-Carlo testing

How to dimension correctly some power system

component considering switching surges?

55

Test Automation with Python script

Test algorithm coded

in Python

Fault application and

breaker reclosing are

randomized

56

Test sequencer: a key part of real-time simulator

By making automated randomized tests (MonteCarlo), we can obtain probabilistic characteristics

of overvoltages.

1

Number of occurences

A-GND FAULT

A-GND

100 2000 runs

0.8

80

0.6

60

0.4

40

0.2

20

0

1.8

2

2.2

2.4

2.6

Voltage peak during fault (pu)

2.8

0

3

2

1

Voltage (pu)

120

Cumulative probability (CDF)

0

-1

Phase A

Phase B

Phase C

-2

0

0.1

0.05

0.15

time (s)

57

PHIL

Power Hardware-In-the-Loop

58

Example of PHIL testing (L2EP, Lilles)

Distributed Energy Storage Systems Application

Used for frequency control on islanded network

Real power electronic device connected to a

simulated grid!

H. Fakham, A. Doniec, F. Colas, X. Guillaud, “A Multi-agents System for a Distributed Power Management

of Micro Turbine Generators Connected to a Grid”, Conference on Control Methodologies and

Technologies for Energy Efficiency (CMTEE 2010) Vilamoura, Portugal http://www.cmtee.org/

62

Frequency regulation tests

The higher the energy storage capacity, the

lower the frequency deviation during fault

Impact of ultracapacitor-based DESS on the frequency response of

an isolated power system after a major generation loss

63

Key References

University of Alberta Power Systems Laboratory

based on RT-LAB

Power Hardware-In-The-Loop Testing of Grid Systems

D. Ocnasu, S. Bacha, I. Munteanu, C. Dufour, D. Roye, “Real-Time PowerHardware-In-the-Loop Facility for Shunt and Serial Power Electronics

Benchmarking”, Proceedings of the 13th European Conference on Power

Electronics and Applications (EPE-2009), Barcelona, Spain, Sept. 8-10, 2009

Advanced Motor Drive Simulation

L.-F. Pak, O. Faruque, X. Nie, V. Dinavahi, “A Versatile Cluster-Based RealTime Digital Simulator for Power Engineering Research”, IEEE Transactions on

Power Systems, Vol. 21, No. 2, pp. 455-465, May 2006.

M. Harakawa, C. Dufour, S. Nishimura, T.Nagano, “Real-Time Simulation of a

PMSM Drive in Faulty Modes with Validation Against an Actual Drive System”,

Proceedings of the 13th European Conference on Power Electronics and

Applications (EPE-2009), Barcelona, Spain, Sept. 8-10, 2009

RT-LAB application booklet with over 30 applications explained

from motor drives and power electronics to large power systems.

Opal-RT Partial Customer List

Opal-RT Technologies

2006.09.28

65

Opal-RT Clients involved in Electric Motor Drive and

Power Grid Studies

Ford

66

Please contact me if you have any questions

christian.dufour@opal-rt.com

67

Appendix 1: How to use RT-LAB for

power system applications?

68

How to use RT-LAB for power system applications?

1- Design your model in Simulink

and SimPowerSystems

2- Identify natural delay in your

model (ex: transmission lines)

3- Make top-level groups in your

Simulink model, these will be

assigned to different CPUs of the

simulator

4- Add I/O block in the model if

necessary

69

How to use RT-LAB for power system applications?

1- Design your model in Simulink and SimPowerSystems

We choose here a SPS demo named: power_PSS.mdl

70

How to use RT-LAB for power system applications?

2- Identify power line to make parallel distributed simulation

71

How to use RT-LAB for power system applications?

3- Choose a task separation and make Subsystems

CPU #1

CPU #2

72

How to use RT-LAB for power system applications?

4- Some optimizations: put controllers in a separate CPU

because it can run at slower rate

Also put monitoring in a separate subsystem

Controls

Monitoring

73

How to use RT-LAB for power system applications?

You can put your own ‘C’ code in any of the cores

You just have to use a S-function ‘wrapper’

int main()

{

printf("hello, world");

printf(“I want to do real-time simulations");

return 0;

}

74

How to use RT-LAB for power system applications?

5- Adding I/Os

Let’s add an analog output from the RT-LAB library

75

How to use RT-LAB for power system applications?

Let’s output the Alternator Excitation voltage

76

How to use RT-LAB for power system applications?

The alternator excitation voltage can now be read on the

front panel of the simulator

77

How to use RT-LAB for power system applications?

Most commercial I/O

cards can be supported

Opal can supply the

source code of

communication driver

examples to enable users

to implement their own

protocols through

Ethernet for Internet

78