mems endovascular pressure sensors

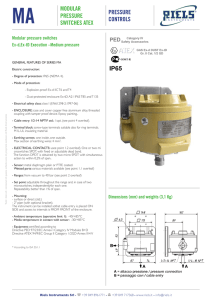

advertisement

1 MEMS ENDOVASCULAR PRESSURE SENSORS December 14, 2007 Jonathan Brickey, Niels Black, Charles Wang Anatomy of the Heart 2 Vena Cava Right Atrium Right Ventricle Pulmonary Arteries Lungs Pulmonary Veins Left Atrium Left Ventricle Aorta http://www.nhlbi.nih.gov/health/dci/Diseases/pda/pda_heartworks.html Body Abdominal Aorta Aneurysm 3 2 cm Healthy Blood Pressure Diastole: <80 mmHg (11 kPa) Systole: <120 mmHg (16 kPa) 6 cm Hypertension Stage 2 Diastole: >100 mmHg (13 kPa) Systole: >160 mmHg (21 kPa) http://www.ultrasoundspecialists.com/screenings.html Prevalence of AAA 4 10th leading cause of death – 65-74 years old 5-7% men over 60 diagnosed with AAA 1-3% men over 65 experience aortic rupture 75-90% mortality rate from rupture 11:1 male:female ratio – 60-64 years old Methods of Treatment 5 Open Repair Endovascular Repair http://www.nhlbi.nih.gov/health/dci/Diseases/arm/arm_treatments.html http://www.vascularweb.org/_CONTRIBUTION_PAGES/Patient_Information/NorthPoint/Abdominal_Aortic_Aneurysm.html EndoSure by CardioMEMS 6 EndoSure Wireless AAA Pressure Measurement System Permanently implanted Radio frequency transmission Radio frequency powered Size of a paper clip Biocompatible http://www.cardiomems.com/content.asp?display=medical+mb&expand=ess http://www.physorg.com/news10533.html Design Record 7 Jay S. Yadav, M.D and Mark G. Allen 1995 – cofound CardioMEMS 2005 – EndoSure sensor invented April, 2007 – granted FDA approval http://www.physorg.com/news10533.html 8 1967 C. C. Collins “Miniature Passive Pressure Transensor for Implanting in the Eye “ 9 1992 Lars Rosengren 1995, William N.Carr, NJIT Hartley Oscillator 1999-2002 Mark Allen, GA Tech 10 Wireless micromachined ceramic pressure sensors High temperature self packaged wireless ceramic pressure sensor 2006 – Mark Allen, GA Tech 11 Flexible Wireless Passive Pressure Sensors for Biomedical Applications Flexible Substrates: Types 12 Liquid Crystal Polymers (LCP) Almost as ordered as fully crystalline solids Chemically inert Easy to fabricate Polyamide Films Kapton-E thermal (DuPont) expansion coefficient same as Cu 13-50 micron thickness Flexible Substrates: Advantages 13 For machining application: Very high dimensional stability High etchability – heavily isotropic For biomedical applications: Flexibility allows less invasive implantation High levels of chemical inertness MEMS Screenprinting 14 Additive process: Mesh overlay – polyester or steel Places where material does not go are “painted” over Mesh screen placed on substrate, liquid poured over MEMS Screenprinting 15 Advantages/Disadvantages: Cheap! Does not require pressurization or extremely expensive equipment, like lithography Mesh can be reused Not particularly precise Features can be no smaller than mesh spacing (~50 µm) Lithography 16 Lithography mask for Inductor-Capacitor setup Cross-section of Cu application (Fonseca 2006) Capacitance vs. Pressure 17 r0 C 2 [ 0 0 d 0 2w(r ) ]rdr 2 r0 0 0 2 w(r ) (1 )rdr d0 d0 3(1 2 ) 2 2 2 w(r ) p [ r r ] 0 0 2 16 Eh Power and Signal Transmission 18 V2 L1 dI1 dI LM 2 dt dt Final Output 19 Problems in Simplification 20 Actual capacitor shape not circular: “…tapered in the center to reduce deflection and avoid shorting out the capacitor…” (Fonseca 2006) Circular model shorts out just before 13 kPa Inductance Very simplified: Most MEMS inductors use complicated programs Future Improvements 21 Major limitations: Size, Sensitivity, Transmission Distance MEMS fabrication results in increased sensitivity Size and Transmission Distance invariably linked Other Possible Design Improvements 22 Finite element analysis of coil design inductance Substrates with low dielectric constants Hartley oscillators or other more complex CMOS for improving sensitivity or transmission distance References 23 Wiemer, M., Frömel, J., Jia, C., Geßner, T., “Bonding and contacting of MEMS-structures on wafer level.” The Electrochemical Society - 203rd meeting, Paris (France), 2003 April 27- May 2 Fonseca, M.A.; English, J.M.; von Arx, M.; and Allen, M.G., "Wireless Micromachined Ceramic Pressure Sensor for High Temperature Applications," IEEE J. Microelectromechanical Systems, vol. 11, no.4, p. 33743 (2002) Fonseca, M.A., Kroh, J., White, J., and Allen, M.G., “Flexible Wireless Passive Pressure Sensors for Biomedical Applications,” Tech. Dig. Solid-State Sensor, Actuator, and Microsystems Workshop (Hilton Head 2006), June 2006 References (continued) 24 “New Medical Device Combines Wireless and MEMS Technology,” Physorg.com, February 03, 2006, December 08, 2007, <http://www.physorg.com/news10533.html> Rosengren, L., Backlund, Y., Sjostrom, T., Hok, E., and Svedbergh, B., “A System for Wireless Intra-Ocular Pressure Measurements Using a Silicon Micromachined Sensor,” (1992) Collins, C.C., “Miniature Passive Pressure Transensor for Implanting in the Eye,” IEEE Transactions on Biomedical Engineering, vol. BME-14, no. 2, April, 1967 Allen, M.G., “Implantable micromachined wireless pressure sensors: approach and clinical demonstration,” 2nd International Workshop on BSN 2005 Wearable and Implantable Body Sensor Networks, 2005, p 40-1.