Chap 4 Outlines

advertisement

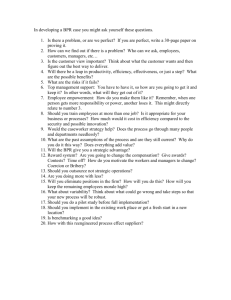

Chapter 4 Process Planning and Design Processes What is a process? Suppose Arlington decides to start a public bus system. What would be some processes that need to be designed? Process flow diagrams – getting gas at a 7-Eleven How much detail should be shown? Designing Processes Designing a process includes: • selecting type of process – streamlined, flexible, off-the-shelf, etc. • outsourcing plans – how much to make vs. buy • • • • • type of technology and degree of automation facility design and layout routing of work equipment, materials, and personnel plans integrating process design with product design Concurrent Engineering (or Simultaneous Engineering) Design product and processes concurrently Traditional approach: product idea marketing decides on features design engineers make technical designs mfg. engineers design processes production dept. tries to make it purchasing dept. orders materials Concurrent Engineering: create a cross-functional, design-build team that includes people from marketing, design engr., mfg. engr., production, and purchasing. This teams makes all planning and design decisions together. Business Process Reengineering (BPR) BPR – a radical change in a business process to achieve breakthrough improvements If we were starting from scratch, with a blank sheet of paper, how would we design the process Now, how can we change our current process to the new process BPR became a hot consulting trend in the early 1990s BPR was sometimes used as an excuse by top executives to downsize their workforce Do you think fewer employees should be needed after a BPR effort? Basic Process Design Product-focused design (e.g., production line) – equipment is organized for a certain type of product – assembly line, production line, continuous production, line flow production – lower cost per unit – little flexibility to change products – fewer labor skills required – less training – higher initial investment – examples: TVs, cars, cafeteria, canned corn, paper, Papa John’s pizza Process-focused design (e.g., job shop) – equipment is organized by type of process (departments) – also called intermittent production or job shop – higher cost per unit – most flexibility – large variety of product designs – more labor skill required – more complex production planning and control – examples: machine shop, hospital, print shop Flow of products in production line vs. job shop Cellular Manufacturing/Group Technology – a mix of product-focused and process-focused designs – product-focused cells within a process-focused shop – gain cost efficiencies for high-volume products within the more flexible job shop Functional Layout Debur 1 Debur 2 Drill 1 Debur 3 Grinder 1 Grinder 1 Drill 2 Debur 4 Grinder 1 Saw 1 Grinder 1 Saw 3 Mill 1 Lathe 1 Drill 3 Lathe 2 Saw 2 Saw 4 Mill 2 Lathe 3 Mill 3 Mill 4 GT Cell (Cellular) Layout Lathe 3 Raw Material Saw 2 Grinder 3 GT Cell Drill 1 Debur 3 Finished Product Mill 1 Compaq Changes to Produce-to-Order (example of process design change) Compaq Computer Corporation has scrapped its long assembly lines and now makes its personal computers with three-person cells that assemble the computers produce-to-order. In this arrangement, the three-person team looks at the next customer’s order on a monitor to see the attributes of the computer to be assembled (accessories, type of drives, etc.) and assembles the computer specifically for that customer. In the three-person cells, one person prepares all the subassemblies that go into a computer. The second person installs these into the computer’s frame. And the third person performs all the tests to make sure the circuits are connected properly. In this method of production, parts and subassemblies are inventoried before customer orders are received, but finished products are not; final assembly occurs only after receipt of customer orders. This allows Compaq to match production to customer orders and reduces the cost of every step of production—inventory, handling, freight, and unsold goods. Shifting to a produce-to-order system also decreases Compaq’s dependence on market forecasts. Compaq says that the output of each employee in the three-person cell increased 23 percent and output per square-foot of factory floor space increased 16 percent compared to produce-to-stock assembly lines. Breakeven Analysis Total Cost = annual Fixed Cost + Variable cost per unit*(annual Quantity) TC = FC + v(Q) Total Revenue = selling Price per unit*(annual Quantity) TR = p(Q) Profit = Total Revenue – Total Cost profit = TR – TC = p(Q) – [FC + v(Q)] Annual Quantity of Indifference: TCA = TCB Example of Breakeven Analysis FC v $0 $200 Low automation—B 80,000 75 High automation—C 200,000 15 Subcontract—A selling price p = $300 per unit 1. Compute the breakeven quantity for each alternative. 2. Compute the annual quantity of indifference between each pair of alternatives. 3. For what range of annual quantities would each alternative be preferred? Breakeven Quantity Annual quantity at which profit = 0; so, TR = TC B: C: A: Quantity of Indifference Annual quantity at which the total costs of two alternatives are equal. A vs. B: B vs. C: A vs. C: Annual Total Costs A B C 200,000 80,000 0 0 640 1,081 Annual Quantity 2,000 Table of Total Costs for Each Alternative Quantity Total Cost A B C 0 1000 1500 2500 Breakeven Analysis Example: A young entrepreneur would like to buy a new riding lawn mower. He typically hires a helper, and the average size lot that is mowed is one acre, for which the customer pays $50. He is trying to decide between three lawn mowers based on the annual fixed cost of each mower and the expected operating cost (including hired labor cost) to mow a one acre lot. A Sears Craftsman lawn tractor costs $1,000 and the operating cost would be $30 per lot. A John Deere lawn tractor costs $5,000 with an operating cost of $20 per lot. A Lawn Boy lawn tractor would cost $3,500 with an operating cost of $25 per lot. a). In the first year, how many lots must be mowed before a positive profit will be earned with the Lawn Boy? b). For each type of lawn mower, how many lots would need to be mowed annually for it to be the preferred alternative?