Biobank - Bimetra

advertisement

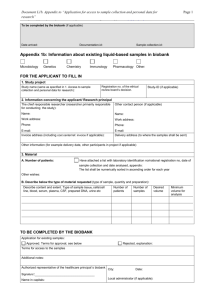

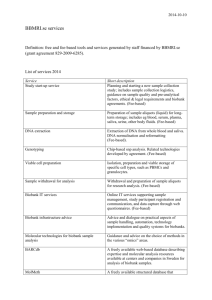

Biobank Infrastructure INTRODUCTIE: PROFIEL EN FUNCTIE 2 Bimetra biobank facility • Fund of the Flemish government (FFEU) for the realisation of a biobank with cryogenic storage capacity of 25.000L Planning and realisation Temporary facility -1P8 (end of 2012 until dec 2014) Total investment plan : 1.326.000,00 € (FFEU) - Jan 2014: initial building plan - March 2014: refining, detailing and finalising the building plans Fase 1: 832.543,69 € - Apr to Nov 2014: Renovation basement (matching funds UZG) and realisation of the building plans - Nov 2014: Move into the new biobank facility - Quality audit (CMI) : Nov 2014 Fase 2: 493.456,31 € - Implementation service level conditions - Implementation of quality control tests - Purchase file digital pathology scanning device - Sample collection: cradle-tograve analyse= mutual effort 3 Location facility Bimetra biobank DWG R, -1 4 How to reach the biobank? • DWG R: in renovation • Temporary access road: • Through building B3 • Go to -1 (basement) • Follow the signs: go in the direction of “dwarsgebouw” • Separate temporary access road to the biobank • Through the underground network of tunnels • Tunnel connecting K1-K2-K3 • From K3 to building B3 • Follow to the end • Separate temporary access road to the biobank 5 Virtual tour: general building plan High quality biobank facility: - Entrance: sas - Sample reception area - Laboratory for sample preparation - Cryogenic facility: - 45 ULT (-80°C) freezers - 6 storage LN2-vessels Invoegen algemeen grondplan met zonering uit iDOCs 6 Access to the biobank: changing area Bimetra biobank: • • • Area with limited/ controlled access (badge reader) Visitors: login register Changing area 7 Changing area: keeping it clean • Changing area: • Put on shoe covers (anti-slip) • Remove “outer wear” (jackets, scarfs…) and put on “inner wear” overcoat • Hand wash facility 8 Overview: entrance – sample reception area - cryofacility 9 Sample reception area 10 Sample reception area • Right zone: “dirty area” • Sample delivery • Transport boxes • Flow: • Unpacking/uncasing of samples • Intake in datamanagement system • Labelling according to following procedures 11 Sample reception area • Go to the “clean area”, sorted according to further procedures Preparation of samples Direct freezing Color coded On dry ice Temporary label Cryovial label 12 Laboratory: sample preparation and QC • Laboratory overview 13 Laboratory: sample preparation and QC • Zone 1: sample prep • Aliquoting of liquid samples • Serum preparation • Cell culture • … 14 Laboratory: sample preparation and QC • Zone 2: sample prep QC • DNA- and RNA extractions • QC on samples • … 15 Laboratory: sample preparation and QC • Zone 3: sample processing • FFPE slide preparation • Cryoslide preparation • future: digital scanning device for slides • … 16 Cryogenic facility: area 1 (ULTs) • Facility for 45 ULT (-80°C) freezers • Existing freezers from P8 < New Brunswick (mixture of models) • New freezers for short/temporary storage of samples < framework agreement with TCPS (Panasonic MDF-U700VX-PE) • New freezers for longterm sample storage < framework agreement with Thermo Fisher Scientific (88600V and 820CV models, with storage racks and boxes) 17 Cryogenic facility: area 1 (ULTs) • Storage racks: • High sample storage efficiëncy • 0,5ml eps, 2 ml cryovials, 4 ml cryovials • PAX, EDTA, 15ml tubes • Ease in traceability of samples < linked in data management system SLims 18 Cryogenic facility: area 1 (ULTs) • High quality facility • “tailormade” airconditioning according to capacity • Maintenance regime: preventive • Monthly maintenance of freezers (registration logbooks): • Ice removal and drying • Checking and cleaning of valves, closures and rubbers • Checking and cleaning of filters • Yearly planned preventive maintenance by the company 19 Cryogenic facility: area 1 (ULTs) • Power supply: separate circuits for each freezers and emergency power • Double monitoring control: • Device generated alarms: • Through potential-free contact < facility management system • Internal device monitoring system (Thermo Fisher Scientific): • short term registration of temperature and events/alarms < USB port • Device generated alarm if case of too high surrounding temperature 20 Cryogenic facility: area 1 (ULTs) • Double monitoring control: • Device independent alarms: Aeroscout • Independent temperature sensor Aeroscout in each ULT < Wifi-network < continuous temperature monitoring and –registration • Independent temperature sensors Aeroscout in the facility < Wifi-network < continuous environment temperature monitoring and –registration 21 Cryogenic facility: area 2 (LN2) • LN2 facility: adapted to safety requirement • LN2 specific flooring • LN2 lines for automatic filling • Oxygen detection (visual/auditive alarms) • Emergency masks for evacuations • Personal safety means 22 Cryogenic facility: area 2 (LN2) • CBS Isothermal freezers (patented new technology) • High storage capacity (± 35.000 2 • • • • ml cryovials/vessel) Automatic filling with build-in monitoring device Small access port Sample tower carrousel Double monitoring Biobank: Quality management system INTRODUCTIE: PROFIEL EN FUNCTIE 24 Quality management system • Quality norm: CMI-CRC guidelines (published oct 2010) • Quality audit Nov 2014: highly positive • Implemented systems: • IDOCs: ZH wide document management system • IML: ZH wide registration system for quality deviations or abnormalities and audit reports • Future objective: ISO-norm for biobanks (involved in ISO working group) • ISO15189 & ISO17025: test labs NOT biobanks 25 Quality system • • • • • • Use of ZH wide system iDOCS and IML Procedure/ process validations Device validations Quality control of samples Full sample traceability and audit trail Following directives and decrees regarding us of HBM • • • Access control (badge) On site back-up freezers, emergency procedures and contracts Double monitoring of all storage devices • • • • Sample and data management through Slims Use of minimal datasets (MDS) and international SPREC coding for sample history Software validation Automatic data retrieval by coupling of other datasystems • • • Involved with local policy HBM < autonomy General flows for sample access Harmonised MTAs and cost models In conclusion: Cryogenic biobank facility is fully operational High quality standards