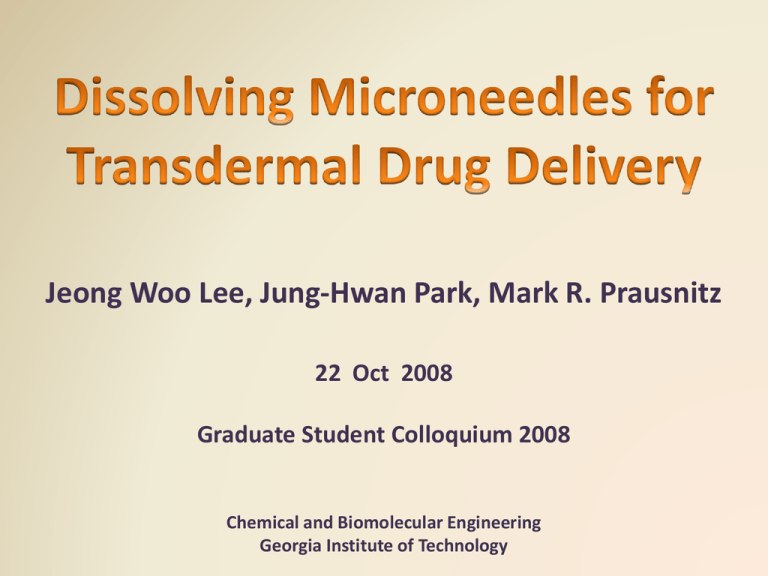

lee_presentation - SMARTech - Georgia Institute of Technology

advertisement

Jeong Woo Lee, Jung-Hwan Park, Mark R. Prausnitz 22 Oct 2008 Graduate Student Colloquium 2008 Chemical and Biomolecular Engineering Georgia Institute of Technology 1. 2. 3. 4. Drug Market Transdermal Drug Delivery Route Dissolving Microneedles Conclusion Public Biotech Sales and R&D Sales ($ billions) R&D Expense ($ billions) Nat. Biotech. 23 (1466) 2005 Oral Delivery Injection Delivery Small MWMW andand High moderately lipophilic hydrophilic Epidermis (Stratum corneum + Viable epidermis) Dermis Hypodermis (Subcutaneous tissue) From www.antbits.co.uk Patent by Alza Corp. in 1971 Microfabrication technique 100 mm “Dissolvable microneedles encapsulating biomolecules” Stratum Corneum Viable Epidermis Dermis Advantages Patient compliance Self-administration No sharp and biohazardous waste Solid platform for biopharmaceuticals Controllable delivery Fabrication Mechanical Strength Drug Delivery Drug Stability Material Selection Safety in use • Biocompatibility • FDA-approved for injection Mechanical property • Reliable insertion Support for biomolecules integrity • Capability of aqueous process • Mild process conditions Hydrogel Centrifugal Force Inverse Mold Centrifugal casting Aqueous drying process External centrifugal force Reliable mass production Solidified Hydrogel Matrix Carboxymethyl Cellulose (CMC) Amylopectin Drug only BSA 600 µm A B C D A: Master Structure C: Amylopectin B: CMC D: BSA Fabrication Mechanical Strength Drug Delivery Drug Stability (A) Force-Displacement Measurement Metal Surface (B) Thumb-Push Demonstration Pig Skin Force-Displacement Sudden yield for high aspect ratio Yield at lower force for CMC Microneedles 1.0 Cone PLA Cone CMC Force (N/needle) 0.8 0.6 0.4 0.2 0.0 0.0 0.1 0.2 0.3 Displacement (mm) 0.4 0.5 Critical Buckling Load (Pcri) Low aspect ratio 16-fold increase Large cross area 2-fold increase Conical (800 µm Length) Diameter (µm) 50 100 200 300 400 600 800 Pyramidal (600 µm Length) Pcri (N) Base (µm) CMC PLA 0.0004 0.0020 50 0.0061 0.0307 100 0.1021 0.5105 200 0.5266 2.6329 300 1.6813 8.4064 400 8.6032 43.0158 500 27.3415 136.7075 600 Conical (600 µm Length) Pcri (N) Pcri (N) Diameter (µm) CMC PLA CMC PLA 0.0020 0.0102 50 0.0007 0.0035 0.0255 0.1271 100 0.0109 0.0546 0.3639 1.8194 200 0.1815 0.9076 1.7798 8.8899 300 0.9362 4.6808 5.5223 27.6113 400 2.9889 14.9447 13.3433 66.7164 500 7.3438 36.7191 27.4795 137.3976 600 15.2945 76.4725 Force-Displacement No sudden yield for low aspect ratio 1.0 (a) Pyramid PLA Pyramid CMC Cone PLA Cone CMC 2:1 Force (N/needle) 0.8 0.6 4:1 0.4 0.2 0.0 0.0 0.1 0.2 0.3 Displacement (mm) 0.4 0.5 Force-Displacement Similar behavior with other material 1.0 (b) PLA Amylopectin 80/20 wt% CMC/BSA BSA CMC Force (N/needle) 0.8 0.6 0.4 0.2 0.0 0.0 0.1 0.2 0.3 Displacement (mm) 0.4 0.5 Thumb-Push Reliable insertion (Pig skin) 150-200 µm insertion depth Rapid dissolution of microneedles 150 µm Backside Tissue Staining Histology Before 1 min 10 sec 15 min 60 min Fabrication Mechanical Strength Drug Delivery Drug Stability If drug is encapsulated in Microneedles Bolus release Backing layer Sustained release Bolus Release Sustained Release Bolus Release Two-step casting Limited dose (a few µg per needle) 1 hour application time stratum corneum 600 µm 200 µm Sustained Release Two-step casting High dose to milligrams Adjustable release kinetics 600 µm After 12 h 1 mm Cumulative amountof of the the released drugdrug (mg) (mg) released amount Cumulative Controllable Release Type of matrix material skin Sampling Port 1.0 0.8 Receptor Chamber 0.6 Stir bar 0.4 0.2 Carboxymethyl cellulose matrix Amylopectin matrix 0.0 0 1 2 3 4 Time Time (Day) (Day) 5 6 7 released amount Cumulative Cumulative amountof of the the released drugdrug (mg) (µg) Controllable Release Loading amount skin Sampling Port 10 wt% loading 30 wt% loading 40 Receptor Chamber 30 Stir bar 20 10 0 0 1 2 3 4 5 6 Time Time (Hour) (hour) 7 8 9 10 Fabrication Mechanical Strength Drug Delivery Drug Stability Lysozyme Circular Dichroism (Secondary Structure) Functional Activity (Tertiary Structure) Human Growth Hormone (hGH) Functional Activity (Tertiary structure) Pharmacokinetics (In vivo) Heat Denatured, Negative control, Lysozyme microneedles, Lysozyme Microneedles (two months storage), CMC + Lysozyme Circular Dichroism 10 Untreated Microneedle Microneedle after 2 months storage Heat treated 100 Relative Activity (%) 5 CD (mdeg) Functional Activity 0 80 60 40 -5 20 -10 0 200 220 240 Wavelength (nm) 260 A B C Lysozyme treatment D Cell population depending on the conc. of hGH No activity loss of the encapsulated hGH hGH (Non-processed) + CMC hGH Microneedles hGH Microneedles (after 3 months) Increase of Cell Population (%) 800 600 400 200 0 1 10 100 hGH Concentration (pg/ml) 1000 Placebo microneedles and hGH microneedles Bolus hGH release in 6 hours hGH microneedles hGH concentration in rat serum (ng/ml) 4 Placebo hGH Microneedles 3 2 1 0 0 5 10 15 Time (Hour) 20 25 Polysaccharide microneedles dissolved inside the skin after the insertion, enabling two different delivery strategies: bolus and sustained delivery CMC dissolving microneedles encapsulated protein drugs, lysozyme and human growth hormone, without the loss of drug stability. Thesis Committee Dr. Mark Prausnitz, Dr. Mark Allen, Dr. Yulin Deng, Dr. Eric Felner, Dr. Lakeshia Taite Microneedle Fabrication Dr. Seong-O Choi Cell Group of Drug Delivery Lab Dr. Robyn Schlicher, Ying Liu, Prerona Chakravarty, Joshua Hutcheson hGH Pharmacokinetics Dr. Laura O’Farrell, Jae hyung Park Funding from NIH