What Is Food Science?

advertisement

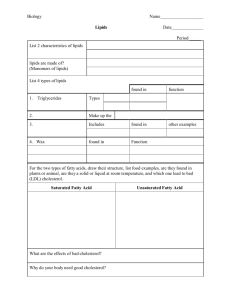

Proteins From the Greek “proteios” or primary. Properties of Amino Acids: Zwitterions are electrically neutral, but carry a “formal” positive or negative charge. Give proteins their water solubility Shape Interactions of Proteins Emulsoids and Suspensiods Proteins should be thought of as solids Not all in a true solution, but bond to a lot of water Can be described in 2 ways: Emulsoids- have close to the same surface charge, with many “shells” of bound water Suspensoids- colloidal particles that are suspended by charge alone Quick Application: Food Protein Systems Milk- Emulsoid and suspensoid system Classified as whey proteins and caseins Casein - a phosphoprotein in a micelle structure Suspensoid - coagulates at IEP (casein) Egg (Albumen) – Emulsoid Surface denatures very easily Heating drives off the structural water and creates a strong protein to protein interaction Cannot make foam from severely denatured egg white, requires bound water and native conformation Functional Properties of Proteins 3 major categories Hydration properties Protein to water interactions Structure formation Dispersion, solubility, adhesion, viscosity Water holding capacity Protein to protein interactions Gel formation, precipitation, aggregation Surface properties Protein to interface interactions Foaming and emulsification 1. Hydration Properties (protein to water) Most foods are hydrated to some extent. Behavior of proteins are influenced by the presence of water and water activity Dry proteins must be hydrated (food process or human digestion) Solubility- as a rule of thumb, denatured proteins are less soluble than native proteins Many proteins (particularly suspensoids) aggregate or precipitate at their isoelectric point (IEP) Viscosity- viscosity is highly influenced by the size and shape of dispersed proteins Influenced by pH Swelling of proteins Overall solubility of a protein 2. Structure Formation (protein to protein) Gels - formation of a protein 3-D network is from a balance between attractive and repulsive forces between adjacent polypeptides Gelation- denatured proteins aggregate and form an ordered protein matrix Plays major role in foods and water control Water absorption and thickening Formation of solid, visco-elastic gels In most cases, a thermal treatment is required followed by cooling Yet a protein does not have to be soluble to form a gel (emulsoid) Texturization – Proteins are responsible for the structure and texture of many foods Meat, bread dough, gelatin Proteins can be “texturized” or modified to change their functional properties (i.e. salts, acid/alkali, oxidants/reductants) Can also be processed to mimic other proteins (i.e. surimi) 3. Surface Properties (protein to interface) Emulsions- Ability for a protein to unfold (tertiary denaturation) and expose hydrophobic sites that can interact with lipids. Alters viscosity Proteins must be “flexible” Overall net charge and amino acid composition Foams- dispersion of gas bubbles in a liquid or highly viscous medium Solubility of the protein is critical; concentration Bubble size (smaller is stronger) Duration and intensity of agitation Mild heat improves foaming; excessive heat destroys Salt and lipids reduce foam stability Some metal ions and sugar increase foam stability Factors Affecting Changes to Proteins Denaturation Aggregation Salts Gelation Changes to Proteins Native State The natural form of a protein from a food The unique way the polypeptide chain is oriented There is only 1 native state; but many altered states The native state can be fragile to: Acids Alkali Salts Heat Alcohol Pressure Mixing (shear) Oxidants (form bonds) and antioxidants (break bonds) Changes to Proteins Denaturation Any modification to the structural state The structure can be re-formed If severe, the denatured state is permanent Denatured proteins are common in processed foods Decreased water solubility (i.e. cheese, bread) Increased viscosity (fermented dairy products) Altered water-holding capacity Loss of enzyme activity Increased digestibility Changes to Proteins Temperature is the most common way to denature a protein Both hot and cold conditions affect proteins Heating affects the tertiary structure Every tried to freeze milk? Eggs? Mild heat can activate enzymes Hydrogen and ionic bonds dissociate Hydrophobic regions are exposed Hydration increases, or entraps water Viscosity increases accordingly Changes to Proteins We discussed protein solubility characteristics Solubility depends on the nature of the solution Water-soluble proteins generally have more polar amino acids on their surface. Less soluble proteins have less polar amino acids and/or functional groups on their surface. Isoelectric Precipitations Proteins ---++ have no net charge at their IEP ----++ -++ -- ++ ++ ++ ++ ++ ++ Strong Repulsion (net negative charge) -- -- -- --- Aggregation (net neutral charge) Strong Repulsion (net positive charge) ++ -++ ++ ++ ++ --++ -++ ++ ++ Isoelectric Precipitations Proteins -- --- -- -- -- Na+ can be “salted out”, adding charges Na+ Na+ Aggregation (net neutral charge) ++ ++ ++ ++ ++ ++ ClCl- Cl- Measuring IEP Precipitations Empirical measurements for precipitation A protein is dispersed in a buffered solution Add salt at various concentrations Add alcohols (disrupt hydrophobic regions) Change the pH Add surfactant detergents (i.e. SDS) Centrifuge and The measure quantitatively pellet will be insoluble protein The supernatant will be soluble protein Gel Formation Many foods owe their physical properties to a gel formation. Influences quality and perception. Cheese, fermented dairy, hotdogs, custards, etc As little as 1% protein may be needed to form a rigid gel for a food. Most protein-based gels are thermally-induced Thermally irreversible gels are most common Cause water to be entrapped, and a gel-matrix formation Gel formed during heating, maintained after cooling Will not reform when re-heated and cooled Thermally reversible gels Gel formed after heating/cooling. Added heat will melt the gel. What is more important in foods? Protein precipitation or Protein solubilization ??? Effects of Food Processing Processing and Storage Decreases Loss of nutritional value in some cases Severity Loss spoilage of foods, increases shelf life of processing of functionality Denatured Both proteins have far fewer functional aspects desirable and undesirable flavor changes Processing and Storage Proteins are affected by Heat Extremes in pH (remember the freezing example?) Oxidizing conditions Oxidizing additives, lipid oxidation, pro-oxidants Reactions with reducing sugars in browning rxns Processing and Storage Mild heat treatments (< 100°C) May slightly reduce protein solubility Cause some denaturation Can inactive some enzymes Improves digestibility of some proteins Severe heat treatments (for example: >100°C) Some sulfur amino acids are damaged Deamination can occur Release of hydrogen sulfide, etc (stinky) Release of ammonia (stinky) Very high temperatures (>180°C) Some of the roasted smells that occur with peanuts or coffee Enzymes A quick review, since we know the basics already Enzyme Influencing Factors Enzymes are proteins that act as biological catalysts They are influenced in foods by: Temperature pH Water activity Ionic strength (ie. Salt concentrations) Presence of other agents in solution Metal chelators Reducing agents Other inhibitors Also factors for Inhibition, including: Oxygen exclusion and Sulfites Enzyme Influencing Factors Temperature-dependence of enzymes Every enzyme has an optimal temperature for maximal activity The rate/effectiveness of an enzyme: Enzyme activity For most enzymes, it is 30-40°C Many enzymes denature >45°C Each enzyme is different, and vary by isozymes Often an enzyme is at is maximal activity just before it denatures at its maximum temperature pH Like temp, enzymes have an optimal pH where they are maximally active Generally between pH 4 and 8 with Most many exceptions have a very narrow pH range where they show activity. This influences their selectivity and activity. Water Activity Enzymes need free water to operate Low Aw foods have very slow enzyme reactions Ionic Strength Some ions may be needed by active sites on the protein Ions may be a link between the enzyme and substrate Ions change the surface charge on the protein Ions may block, inhibit, or remove an inhibitor Others, enzyme-specific Enzymes Before a chemical reaction can occur, the activation energy (Ea) barrier must be overcome Enzymes are biological catalysts, so they increase the rate of a reaction by lowering Ea Enzymes The effect of temperature is two-fold From about 20, to 35-40°C (for enzymes) From about 5-35°C for other reactions Q10-Principal: For every 10°C increase in temperature, the reaction rate will double Not an absolute “law” in science, but a general “rule of thumb” At higher temperatures, some enzymes are much more stable than other enzymes Enzymes Enzymes are sensitive to pH – most enzymes active only within a pH range of 34 units (catalase has max. activity between pH 3 & 10!) The optimum pH depends on the nature of the enzyme and reflects the environmental conditions in which enzyme is normally active: Pepsin pH 2; Trypsin pH 8; Peroxidase pH 6 pH dependence is usually due to the presence of one or more charged AA at the active site. Nomenclature Each enzyme can be described in 3 ways: Trivial name: -amylase Systematic name: -1,4-glucan-glucono-hydrolase substrate reaction Number of the Enzyme Commission: E.C. 3.2.1.1 3- hydrolases (class) 2- glucosidase (sub-class) 1- hydrolyzing O-glycosidic bond (sub-sub-class) 1- specific enzyme Enzyme Class Characterizations 1. Oxidoreductase Oxidation/reduction reactions 2. Transferase Transfer of one molecule to another (i.e. functional groups) 3. Hydrolase Catalyze bond breaking using water (ie. protease, lipase) 4. Lyase Catalyze the formation of double bonds, often in dehydration reations 5. Isomerase Catalyze intramolecular rearrangement of molecules 6. Ligase Catalyze covalent attachment of two substrate molecules 1. OXIDOREDUCTASES Oxidation Is Losing electrons Reduction Is Gaining electrons Electron acceptor eXm+ reduced Xm2+ e- oxidized Electron donor Redox active (Transition) metals (copper/ iron containing proteins) 1. Oxidoreductases: GLUCOSE OXIDASE -D-glucose: oxygen oxidoreductase Catalyzes oxidation of glucose to glucono- -lactone -D-glucose Glucose oxidase D glucono--lactone FAD H2O2 Catalase FADH2 O2 + H2 O D Gluconic acid H2O + ½ O2 Oxidation of glucose to gluconic acid 1. Oxidoreductases: Catalase hydrogenperoxide: hydrogenperoxide oxidoreductase Catalyzes conversion of 2 molecules of H2O2 into water and O2: H2O2 ------------------- H2O +1/2 O2 Uses H2O2 When coupled with glucose oxidase the net result is uptake of ½ O2 per molecule of glucose Occurs in MO, plants, animals 1. Oxidoreductases: PEROXIDASE (POD) donor: hydrogenperoxide oxidoreductase Iron-containing enzyme. Has a heme prosthetic group N N Fe N N Thermo-resistant – denaturation at ~ 85oC Since is thermoresistant - indicator of proper blanching (no POD activity in blanched vegetables) 1. Oxidoreductases: POLYPHENOLOXIDASES (PPO) Phenolases, PPO Copper-containing enzyme Oxidizes phenolic compounds to o-quinones: Catalyze conversion of mono-phenols to o-diphenols In all plants; high level in potato, mushrooms, apples, peaches, bananas, tea leaves, coffee beans Tea leaf tannins Catechins Procyanidins Gallocatechins Catechin gallates PPO O2 o-Quinone + H2O Colored products Action of PPO during tea fermentation; apple/banana browning 1. Oxidoreductases: LIPOXYGENASE H H ……… H …….. C C C C cis cis H H + O2 H H H C H C C C cis H C trans …….. OOH Oxidation of lipids with cis, cis groups to conjugated cis, trans hydroperoxides. Enzymes !!! We have observed carbohydrate hydrolysis Sucrose into glu + fru Starch into dextrins, maltose, and glucose We will observe lipid hydrolysis Break-down of fats and oils Enzyme-derived changes So….the enzyme discussion is not over yet. Enzymes !!! We have observed carbohydrate hydrolysis Sucrose into glu + fru Starch into dextrins, maltose, and glucose We will observe lipid hydrolysis Break-down of fats and oils Enzyme-derived changes So….the enzyme discussion is not over yet. Worthington Enzyme Manual http://www.worthingtonbiochem.com/index/manual.html IUPAC-IUBMB-JCBN http://www.chem.qmul.ac.uk/iubmb/enzyme Lipids Lipids Main functions of lipids in foods Energy and maintain human health Influence on food flavor Fatty acids impart flavor Lipids carry flavors/nutrients Influence on Solids food texture or liquids at room temperature Change with changing temperature Participation in emulsions Lipids Lipids are soluble in many organic solvents Ethers (n-alkanes) Alcohols Benzene DMSO (dimethyl sulfoxide) They are generally NOT soluble in water C, H, O and sometimes P, N, S Lipids Neutral Lipids Waxes Long-chain alcohols (20+ carbons in length) Cholesterol esters Vitamin A esters Vitamin D esters Conjugated Lipids Triacylglycerols Phospholipids, glycolipids, sulfolipids “Derived” Lipids Fatty acids, fatty alcohols/aldehydes, hydrocarbons Fat-soluble vitamins Lipids Structure Triglycerides or triacylglycerols Glycerol + 3 fatty acids >20 different fatty acids Lipids 101-What are we talking about? Fatty acids- the building block of fats A fat with no double bonds in it’s structure is said to be “saturated” (with hydrogen) Fats with double bonds are referred to as mono-, di-, or tri- Unsaturated, referring to the number of double bonds. Some fish oils may have 4 or 5 double bonds (polyunsat). Fats are named based on carbon number and number of double bonds (16:0, 16:1, 18:2 etc) Lipids liquid triacylglycerides “Oleins” Fat- solid or semi-solid mixtures of crystalline and liquid TAG’s “Stearins” Lipid content, physical properties, and preservation are all highly important areas for food research, analysis, and product development. Many preservation and packaging schemes are aimed at prevention of lipid oxidation. Oil- Nomenclature The first letter C represents Carbon The number after C and before the colon indicates the Number of Carbons The letter after the colon shows the Number of Double Bonds ·The letter n (or w) and the last number indicate the Position of the Double Bonds Saturated Fatty Acids Mono-Unsaturated Fatty Acids Poly-Unsaturated Fatty Acids Lipids Properties depend on structure Length of fatty acids (# of carbons) Short chains will be liquid, even if saturated (C4 to C10) Position of fatty acids (1st, 2nd, 3rd) Degree of unsaturation: Double bonds tend to make them a liquid oil Hydrogenation: tends to make a solid fat Unsaturated fats oxidize faster Preventing lipid oxidation is a constant battle in the food industry Lipids 101-What are we talking about? Fatty acid profile- quantitative determination of the amount and type of fatty acids present following hydrolysis. To help orient ourselves, we start counting the number of carbons starting with “1” at the carboxylic acid end. O C C C C C C C C C C C C C C C C C C 18 1 OH Lipids 101-What are we talking about? For the “18-series” (18:0, 18:1, 18:2, 18:3) the double bonds are usually located between carbons 6=7 9=10 12=13 15=16. O C C C C C C C C C C C C C C C C C C 18 16 15 13 12 10 9 1 OH Lipids 101-What are we talking about? The biomedical field entered the picture and ruined what food scientists have been doing for years with the OMEGA (w) system (or “n” fatty acids). With this system, you count just the opposite. Begin counting with the methyl end Now the 15=16 double bond is a 3=4 double bond or as the biomedical folks call it….an w-3 fatty acid C C C C C C C C C C C C C C C C C C C 1 6 7 3 4 18 9 10 OH Melting Points of Lipids Tuning Fork Analogy-TAG’s Envision a Triacylglyceride as a loosely-jointed E Now, pick up the compound by the middle chain, allowing the bottom chain to hang downward in a straight line. The top chain will then curve forward and form an h Thus the “tuning fork” shape Fats will tilt and twist to this lowest free energy level Lipids Lipids are categorized into two broad classes. The first, simple lipids, upon hydrolysis, yield up to two types of primary products, i.e., a glycerol molecule and fatty acid(s). The other, complex lipids, yields three or more primary hydrolysis products. Most complex lipids are either glycerophospholipids, or simply phospholipids contain a polar phosphorus moiety and a glycerol backbone or glycolipids, which contain a polar carbohydrate moiety instead of phosphorus. Lipids Other types of lipids Phospholipids Structure similar to triacylglycerol High in vegetable oil Egg yolks Act as emulsifiers Fats and Oils… can also be converted to an emulsifier… H O H C O C H C OH H C OH Production of mono- and diglycerides H Use as Emulsifiers Heat fat or oil to ~200°C Add glycerol and alkali Free Fatty Acids will be added to the glycerol Fatty Acid Chain Fats and Oils: Processing Extraction Rendering Pressing oilseeds Solvent extraction Soybean Peanut Rape Seed Safflower Sesame Fats and Oils Further Processing Degumming Refining/Neutralization Oil Refining Remove free fatty acids (alkali + water) Bleaching Remove phospholipids with water Remove pigments (charcoal filters) Deodorization Remove off-odors (steam, vacuum) Where Do We Get Fats and Oils? Neutralization Free fatty acids, phospholipids, pigments, and waxes exist in the crude oil These may promote lipid oxidation and off-flavors Removed by heating fats and adding caustic soda (sodium hydroxide) or soda ash (sodium carbonate). Impurities settle to the bottom and are drawn off. The refined oils are lighter in color, less viscous, and more susceptible to oxidation. Bleaching The removal of color materials in the oil. Heated oil can be treated with diatomaceous earth, activated carbon, or activated clays. Colored impurities include chlorophyll and carotenoids Bleaching can promote lipid oxidation since some natural antioxidants are removed. Where Do We Get Fats and Oils? Deodorization Deodorization is the final step in the refining of oils. Steam distillation under reduced pressure (vacuum). Conducted at high temperatures of 235 - 250ºC. Volatile compounds with undesirable odors and tastes can be removed. The resultant oil is referred to as "refined" and is ready to be consumed. About 0.01% citric acid may be added to inactivate prooxidant metals. Where Do We Get Fats and Oils? Rendering Primarily for extracting oils from animal tissues. Oil-bearing tissues are chopped into small pieces and boiled in water. The oil floats to the surface of the water and skimmed. Water, carbohydrates, proteins, and phospholipids remain in the aqueous phase and are removed from the oil. Degumming may be performed to remove excess phospholipids. Remaining proteins are often used as animal feeds or fertilizers. Where Do We Get Fats and Oils? Mechanical Pressing Mechanical pressing is often used to extract oil from seeds and nuts with oil >50%. Prior to pressing, seed kernels or meats are ground into small sized to rupture cellular structures. The coarse meal is then heated (optional) and pressed in hydraulic or screw presses to extract the oil. Olive oils is commonly cold pressed to get virgin or extra virgin olive oil. It contains the least amount of impurities and is often edible without further processing. Some oilseeds are first pressed or placed into a screwpress to remove a large proportion of the oil before solvent extraction. Where Do We Get Fats and Oils? Solvent Extraction Organic solvents such as petroleum ether, hexane, and 2-propanol can be added to ground or flaked oilseeds to recover oil. The solvent is separated from the meal, and evaporated from the oil. Neutralization Free fatty acids, phospholipids, pigments, and waxes exist in the crude oil These promote lipid oxidation and off-flavors Removed by heating fats and adding caustic soda (sodium hydroxide) or soda ash (sodium carbonate). Impurities settle to the bottom and are drawn off. The refined oils are lighter in color, less viscous, and more susceptible to oxidation. Bleaching The removal of color materials in the oil. Heated oil can be treated with diatomaceous earth, activated carbon, or activated clays. Colored impurities include chlorophyll and carotenoids Bleaching can promote lipid oxidation since some natural antioxidants are removed. Hydrogenating Vegetable oils can produce trans-fats H H C C Cis- H C C Trans- H http://www.foodnavigator-usa.com/Regulation/Trans-fats-Partially-hydrogenated-oils-should-be-phasedout-in-months-not-years-says-expert-as-FDA-considers-revoking-their-GRAS-status The cis- and trans- forms of a fatty acid Lipid Oxidation Effects of Lipid Oxidation Flavor and Quality Loss Nutritional Quality Loss Rancid flavor Alteration of color and texture Decreased consumer acceptance Financial loss Oxidation of essential fatty acids Loss of fat-soluble vitamins Health Risks Development of potentially toxic compounds Development of coronary heart disease Simplified scheme of lipoxidation H H H H H H H H H H H H R C C C C R R C C C C R R C C C C R H H + Catalyst H * + Oxygen H O O LIPID OXIDATION and Antioxidants Fats are susceptible to hydrolyis (heat, acid, or lipase enzymes) as well as oxidation. In each case, the end result can be RANCIDITY. For oxidative rancidity to occur, molecular oxygen from the environment must interact with UNSATURATED fatty acids in a food. The product is called a peroxide radical, which can combine with H to produce a hydroperoxide radical. The chemical process of oxidative rancidity involves a series of steps, typically referred to as: Initiation Propagation Termination Lipid Oxidation Initiation of Lipid Oxidation There must be a catalytic event that causes the initiation of the oxidative process Enzyme catalyzed “Auto-oxidation” Excited oxygen states (i.e singlet oxygen): 1O2 Triplet oxygen (ground state) has 2 unpaired electrons in the same spin in different orbitals. Singlet oxygen (excited state) has 2 unpaired electrons of opposite spin in the same orbital. Metal ion induced (iron, copper, etc) Light Heat Free radicals Pro-oxidants Chlorophyll Water activity Considerations for Lipid Oxidation Which hydrogen will be lost from an unsaturated fatty acid? The longer the chain and the more double bonds….the lower the energy needed. Oleic acid Radical Damage, Hydrogen Abstraction Formation of a Peroxyl Radical Propagation Reactions Initiation Ground state oxygen Hydroperoxide decomposition Peroxyl radical Start all over again… Hydroperoxide New Radical Hydroxyl radical!! Propagation of Lipid Oxidation H H H H H H H H H H H H R C C C C R R C C C C R R C C C C R H H + Catalyst H * + Oxygen H O O Termination of Lipid Oxidation Although radicals can “meet” and terminate propagation by sharing electrons…. The presence or addition of antioxidants is the best way in a food system. Antioxidants can donate an electron without becoming a free radical itself. Antioxidants and Lipid Oxidation BHT – butylated hydroxytoluene BHA – butylated hydroxyanisole TBHQ – tertiary butylhydroquinone Propyl gallate Tocopherol – vitamin E NDGA – nordihydroguaiaretic acid Carotenoids Physical Properties of Lipids Fats and Oils Melting and Texture Think of a fat as a crystal, that when heated will melt. Length of fatty acid chain Short chains have low melting points Oils vs soft fats vs hard fats Degree of unsaturation Unsaturation = presence of double bonds Unsaturation = low melting point Fats and Oils in Foods SOLID FATS are made up of microscopic fat crystals. Many fats are considered semi-solid, or “plastic”. PLASTICITY is a term to describe a fat’s softness or the temperature range over which it remains a solid. Even a fat that appears liquid at room temperature contains a small number of microscopic solid fat crystals suspended in the oil…..and vice versa PLASTIC FATS are a 2 phase system: Plasticity is a result of the ratio of solid to liquid components. Solid phase (the fat crystals) Liquid phase (the oil surrounding the crystals). Plasticity ratio = volume of crystals / volume of oil Measured by a ‘solid fat index’ or amount of solid fat or liquid oil in a lipid As the temperature of a plastic fat increases the fat crystals melt and the fat will soften and eventually turn to a liquid. Shortening Plastic range Temperature range over which it is solid (melting point) Want a large plastic range for shortening Want it to remain a solid at high temps. Holding air during baking Frying Oils Want a short plastic range Liquid or low melting point Do not want mono- or diglycerides or oil will smoke when heated Must be stable to oxidation, darkening Methyl silicone may be added to help reduce foaming Fat and Oil: Further Processing Winterizing Cooling a lipid to precipitate solid fat crystals DIFFERENT from hydrogenation Plasticizing Modifying fats by melting (heating) and solidifying (cooling) Tempering Holding the fat at a low temperature for several hours to several days to alter fat crystal properties (Fat will hold more air, emulsify better, and have a more consistent melting point) Fat Crystals: α, ß’, ß The proportion of fat crystals to oil also depends on the melting points of the crystals. Most fats exhibit polymorphism, meaning they can exist in one of several crystal forms. These crystal forms are 3-D arrangements. Three primary crystal forms exist: α-form (not very dense, lowest melting point), unstable ß’-form (moderate density, moderate melting point), not as stable ß-form (most dense, highest melting point), very stable Rapid cooling of a heated fat will result in fine α crystals. Slow cooling favors formation of the coarse ß crystals. Fat crystals are easily observed when butter/shortening is melted and allowed to re-solidify. Fat Crystals in Commercial Oils α, ß’, ß Crystal forms are largely dependent on the fatty acid composition of the lipid Some fats will only solidify to the ß-form Soybean, peanut, corn, olive, coconut, cocoa butter, etc Other fats will harden to the ß’-form Mono-acid lipids (3 of the same fatty acids) Mixed lipids or heterogeneous lipids (different FA’s) Cottonseed, palm, canola, milk fat, and beef tallow ß’ forms are good for baked goods, where a high plastic range is desired…..but... Chocolate Bloom In chocolate (cocoa butter), the desired stable crystal form is the ß-form Processing involves conching (blending cocoa and sugar to a super-fine particle) and Tempering (heating/cooling steps). Together, these give ß crystals to the final chocolate Fine chocolates control this well. Chocolate Making chocolate The polymorphs of chocolate affect quality and keeping quality. When making chocolate, the tempering process alters the fat crystals and transforms to a predominance of ß-forms. This process begins with the formation of some ß crystals as “seeds” from which additional crystals form. The chocolate is then heated to just below the temperature for ß-forms to melt (thus melting all other forms), and allows the remaining fats to crystalize into ß-forms upon cooling. Chocolate Bloom When chocolate has been heated and cooled, fat and sugar can rise to the surface, and change crystalline state (fat) or crystallize (sugar). When melted fat re-cools, less stable and lower melting point α crystals can form. The different crystals also physically look different (white, grey, etc) against the brown background of the chocolate bar.