Cause-and-Effect Diagrams

advertisement

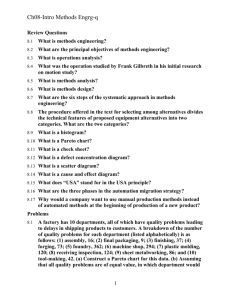

Statistical Process Contol (SPC) Lec-1 1 Quality and SPC The concept of quality has been with us since the beginning of time. Typically the quality of products was described by some attribute such as strength, beauty or finish. However, the mass production of products that the reproducibility of the size or shape of a product became a quality issue. 2 Quality and SPC Quality was obtained by inspecting each part and passing only those that met specifications. With SPC, the process is monitored through sampling. Considering the results of the sample, adjustments are made to the process before the process is able to produce defective parts. 3 Process Variability The concept of process variability forms the heart of SPC. For example, if a basketball player shot free throws in practice, and the player shot 100 free throws every day, the player would not get exactly the same number of baskets each day. Some days the player would get 84 of 100, some days 67 of 100, and so on. All processes have this kind of variation or variability. 4 Process Variability The variation can be partitioned into 2 components. Natural process variation (common cause) or system variation. In the case of the basketball player, this variation would fluctuate around the player's long-run percentage of free throws made. Special cause variation is typically caused by some problem or extraordinary occurrence in the system. In the case of the player, a hand injury might cause the player to miss a larger than usual number of free throws on a particular day. 5 Statistical Process Control (SPC) SPC is a methodology for charting the process and quickly determining when a process is "out of control“. (e.g., a special cause variation is present because something unusual is occurring in the process). The process is then investigated to determine the root cause of the "out of control" condition. When the root cause of the problem is determined, a strategy is identified to correct it. 6 Statistical Process Control (SPC) The management responsible to reduce common cause or system variation as well as special cause variation. This is done through process improvement techniques, investing in new technology, or reengineering the process to have fewer steps and therefore less variation. Reduced variation makes the process more predictable with process output closer to the desired or nominal value. 7 Statistical Process Control (SPC) The process above is in apparent statistical control. Notice that all points lie within the upper control limits (UCL) and the lower control limits (LCL). CL-centerline This process exhibits only common cause variation. 8 The process above is out of statistical control. Notice that a single point can be found outside the control limits (above them). This means that a source of special cause variation is present. Having a point outside the control limits is the most easily detectable out-of-control condition. 9 The graphic above illustrates the typical cycle in SPC. First, the process is highly variable and out of statistical control. Second, as special causes of variation are found, the process comes into statistical control. Finally, through process improvement, variation is reduced. This is seen from the narrowing of the control limits. Eliminating special cause variation keeps the process in control; process improvement reduces the process variation and moves the control limits in toward the centerline of the process. 10 Out-of-Control Conditions Several types of conditions exist that indicate that a process is out of control: Extreme Point Condition: This process is out of control because a point is either above the UCL or below the LCL. 11 Out-of-Control Conditions Control Chart Zones: Control charts can be broken into 3 zones, a, b, & c on each side of the process center line. A series of rules exist that are used to detect conditions in which the process is behaving abnormally to the extent that an out of control condition is declared. 12 Out-of-Control Conditions The probability of having 2 out of 3 consecutive points either in or beyond zone A is an extremely unlikely occurrence when the process mean follows the normal distribution. This criteria applies only to X-bar charts for examining the process mean. X, Y, and Z are all examples of this phenomena. 13 Out-of-Control Conditions The probability of 4 out of 5 consecutive points either in or beyond zone B is also an extremely unlikely occurrence when the process mean follows the normal distribution. Applied to X-bar chart when analyzing a process mean. X, Y, and Z are all examples of this phenomena. 14 Out-of-Control Conditions Runs Above or Below the Centerline: The probability of having long runs (8 or more consecutive points) either above or below the centerline is also an extremely unlikely occurrence when the process follows the normal distribution. Applied to both X-bar and r charts. 15 Out-of-Control Conditions Linear Trends: The probability of 6 or more consecutive points showing a continuous increase or decrease is also an extremely unlikely occurrence when the process follows the normal distribution. Applied to both X-bar and r charts. 16 Out-of-Control Conditions Oscillatory Trend: The probability of having 14 or more consecutive points oscillating back and forth is also an extremely unlikely occurrence when the process follows the normal distribution. Applied to both X-bar and r charts. 17 Out-of-Control Conditions Avoidance of Zone C: The probability of having 8 or more consecutive points occurring on either side of the center line and do not enter Zone C. This phenomena occurs when more than one process is being charted on the same chart, the use of improper sampling techniques, or perhaps the process is over controlled. 18 Out-of-Control Conditions Run in Zone C: The probability of having 15 or more consecutive points occurring the Zone C. This condition can arise from improper sampling, falsification of data, or a decrease in process variability that has not been accounted for when calculating control chart limits, UCL and LCL. 19 The basics Don’t inspect the product, inspect the process. You can’t inspect it in, you’ve got to build it in. If you can’t measure it, you can’t manage it. 20 The SPC steps Basic approach: Awareness that a problem exists. Determine the specific problem to be solved. Diagnose the causes of the problem. Determine and implement remedies. Implement controls to hold the gains achieved by solving the problem. 21 SPC requires the use of statistics Quality improvement efforts have their foundation in statistics. SPC involves the collection tabulation analysis interpretation presentation of numerical data. 22 SPC is comprised of 7 tools: Pareto diagram Histogram Cause and Effect Diagram Check sheet Process flow diagram Scatter diagram Control chart 23 Pareto Principle Alfredo Pareto (1848-1923) Italian Economist: Conducted studies of the distribution of wealth in Europe. 20% of the population has 80% of the wealth Joseph Juran used the term “vital few & trivial many or useful many”. He noted that 20% of the quality problems caused 80% of the dollar loss. 24 Pareto diagram (64) 60 Percent from each cause A pareto diagram is a graph that ranks data classifications in descending order from left to right. 70 50 40 30 20 (13) 10 (10) (6) (3) (2) (2) 0 Causes of poor quality 25 % Complaints Pareto diagram 26 Pareto diagram Sometimes a pareto diagram has a cumulative line. This line represents the sum of the data as they are added together from left to right. 27 Pareto diagram Sometimes a pareto diagram has a cumulative line. This line represents the sum of the data as they are added together from left to right. Above the bars, using the 2nd Y-axis representing the cumulative data, plot the cumulative percentage values in the form of a line. 28 Pareto diagram The cumulative percentage can be computed (dotted line). On the right, add a vertical percent scale equal in length to the scale on the left. Label this from 0% to 100% . 29 Pareto diagram Table 1. Example of a Tabulation of Causes of Ball Bond Lifting for use in a Pareto Chart Ball Lifting Cause Bonder Set-up Issues Unetched Glass on Bond Pad Foreign Contam on Bond Pad Excessive Probe Damage Silicon Dust on Bond Pad Corrosion Bond Pad Peel-off Cratering Resin Bleed-out Others Total Frequency Percent (%) 19 11 9 3 2 1 1 1 1 2 50 38% 22% 18% 6% 4% 2% 2% 2% 2% 4% 100% Cum Percent (%) 38% 60% 78% 84% 88% 90% 92% 94% 96% 100% - 30 Pareto diagram Table 1. Example of a Tabulation of Causes of Ball Bond Lifting for use in a Pareto Chart Ball Lifting Cause Bonder Set-up Issues Unetched Glass on Bond Pad Foreign Contam on Bond Pad Excessive Probe Damage Silicon Dust on Bond Pad Corrosion Bond Pad Peel-off Cratering Resin Bleed-out Others Total Frequency Percent (%) 19 11 9 3 2 1 1 1 1 2 50 38% 22% 18% 6% 4% 2% 2% 2% 2% 4% 100% Cum Percent (%) 38% 60% 78% 84% 88% 90% 92% 94% 96% 100% - 31 Histogram The histogram, graphically shows the process capability and, if desired, the relationship to the specifications and the nominal. It also suggests the shape of the population and indicates if there are any gaps in the data. 32 Histogram 33 Histogram Data Range Frequency 0-10 1 10-20 3 20-30 6 30-40 4 40-50 2 34 Cause-and-Effect Diagrams Show the relationships between a problem and its possible causes. Developed by Kaoru Ishikawa (1953) Also known as … Fishbone diagrams Ishikawa diagrams 35 Cause and Effect “Skeleton” Materials Procedures Quality Problem People Equipment 36 37 Measurement Faulty testing equipment Incorrect specifications Improper methods Inaccurate temperature control Dust and Dirt Environment Human Machines Out of adjustment Poor supervision Lack of concentration Tooling problems Old / worn Inadequate training Quality Problem Defective from vendor Not to specifications Materialhandling problems Materials Poor process design Ineffective quality management Deficiencies in product design Process 38 Cause-and-Effect Diagrams Advantages making the diagram is educational in itself diagram demonstrates knowledge of problem solving team diagram results in active searches for causes diagram is a guide for data collection 39 Cause-and-Effect Diagrams To construct the skeleton, remember: For manufacturing - the 4 M’s man, method, machine, material For service applications equipment, policies, procedures, people 40 Defect Type Shifts 41 COMPONENTS REPLACED BY LAB TIME PERIOD: 22 Feb to 27 Feb 1998 REPAIR TECHNICIAN: Bob TV SET MODEL 1013 Integrated Circuits Capacitors Resistors Transformers Commands CRT |||| |||| |||| |||| |||| |||| || || |||| | 42 Flowcharts Graphical description of how work is done. Used to describe processes that are to be improved. "Draw a flowchart for whatever you do. Until you do, you do not know what you are doing, you just have a job.” Dr. W. Edwards Deming. 43 Flowcharts Activity Decision Yes No 44 Flowcharts 45 Flow Diagrams 46 Process Chart Symbols Operations Inspection Transportation Delay Storage 47 Flow Diagrams 48 49 Scatter Diagram . (a) Positive correlation (b) No correlation (c) Curvilinear relationship The patterns described in (a) and (b) are easy to understand; however, those described in (c) are more difficult. 50 Run Charts Run Charts (time series plot) Examine the behavior of a variable over time. Basis for Control Charts 51 Control Chart 27 Number of defects 24 UCL = 23.35 21 c = 12.67 18 15 12 9 6 LCL = 1.99 3 2 4 6 8 10 Sample number 12 14 16 52 Control Chart 53 SUMMARY SPC using statistical techniques to measure and analyze the variation in processes to monitor product quality and maintain processes to fixed targets. Statistical quality control using statistical techniques for measuring and improving the quality of processes, sampling plans, experimental design, variation reduction, process capability analysis, process improvement plans. 54 SUMMARY A primary tool used for SPC is the control chart, a graphical representation of certain descriptive statistics for specific quantitative measurements of the process. These descriptive statistics are displayed in the control chart in comparison to their "in-control" sampling distributions. The comparison detects any unusual variation in the process, which could indicate a problem with the process. 55 SUMMARY - benefits Provides surveillance and feedback for keeping processes in control Signals when a problem with the process has occurred Detects assignable causes of variation Reduces need for inspection Monitors process quality Provides mechanism to make process changes and track effects of those changes Once a process is stable, provides process capability analysis with comparison to the product tolerance 56