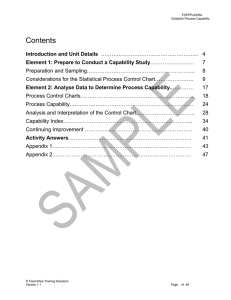

Statistical Techniques for

Achieving Quality

Chapter 20

Achieving Quality Through Continual

Improvement

Claude W. Burrill / Johannes Ledolter

Published by John Wiley & Sons, Inc., 1999

Prepared by Dr. Tomi Wahlström,

University of Southern Colorado

Chapter 20

1

Introduction

Statistical quality control is a branch of

applied statistics dealing with statistical

tools that help control the quality of

products and improve the processes

responsible for these products

Acceptance sampling plans rely on

samples of incoming or outgoing material

to decide whether a lot should be accepted

Chapter 20

2

Introduction

Control charts are important tools for

monitoring processes through the

products they produce

Statistical design of experiments and

experimentation may also be used as a part

of statistical quality control

Chapter 20

3

Sample Inspection

When it is not realistic to use census for

inspection, one must rely on sample

inspection

• Taking a small sample size n from each

shipment lot, inspecting the sampled items,

and counting the number of items meeting the

requirements

Chapter 20

4

Control Charts

Graphical tool used to understand the

production process and to help assure that

the quality of products produced by that

process is consistent (or stable) over time

Easy to explain and apply

• Raise important issues and force their

resolution

• Focus attention on process rather than product

Chapter 20

5

X-bar Charts

Also known as the mean chart

Used in situations where one measures a

continuous variable

Terms associated with it:

• Upper and lower control limits

• Stable process, constant cause system

• Assignable cause

Chapter 20

6

R-Charts

Also known as the range chart

Plots the ranges of samples taken over

time and monitors the variability of the

process over time

Both X-bar and R-charts are used whenever

we measure so called “variable” aspects of

a process

Chapter 20

7

Control Charts for Attribute Data

p-Charts

• Used to monitor the proportion of defective items

c-Charts

• Used to keep track of the number of defects or

flaws on a product

Both used for attribute data

• Data that describes the presence or absence of a

certain characteristic

Chapter 20

8

Process Capability

Typically, a product must meet certain

specifications called a target value (Tg),

lower specification limit (LSL), and an upper

specification limit (USL)

If the products meet the specifications, the

process is capable of producing according

to the given specifications

Capability Index (Cp)

Chapter 20

9

Statistical Design of Experiments

Information can be collected in an active or

passive manner and must be collected

according to an experimental plan

Important principles to consider:

• Randomization

• Blocking

– “Block whatever you can block, and randomize

whatever you can’t block.”

Chapter 20

10

Questions?

Chapter 20

11

Copyright© 1999 John Wiley & Sons Inc. All rights reserved.

Reproduction or translation of this work beyond that permitted

in section 117 of the United States Copyright Act without the

express written permission of the copyright owner is unlawful.

Request for further information should be addressed to the

permission department, John Wiley & Sons, Inc. The

purchaser may make back-up copies for his/her own use only

and not for distribution or resale. The Publisher assumes no

responsibility for errors, omissions, or damages, caused by the

use of these programs or from the use of the information

contained herein.

Chapter 20

12