NONA Composite Tool Fab 20150317-2

advertisement

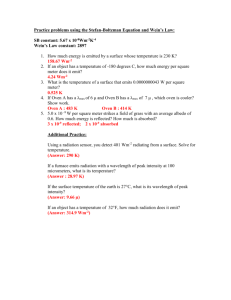

No-Oven, No-Autoclave Composite Tool Fabrication Ben Dietsch President dietschb@nonacomposites.com 937-490-4817 Make your composite parts faster, larger, and with more operational flexibility • Epoxy Resins • Tooling, Parts, and Curing Systems • Process Engineering Services A new company…..with 200+ years of composite experience • Founded 2013 as a spinoff of Cornerstone Research Group (Dayton, OH) • Core team brings 40+ years of composite material, processing, and industry experience • Sales team brings an additional 100+ years of composite experience • Advisory team brings 60+ years of composite experience Resin Systems | Tooling and Parts Manufacturing| Process Engineering Ogive Tool for NASA Panel Tool for NASA Our goods and services enable significant production cost (20+%) and time (30+%) savings, manufacturing flexibility, and tens of thousands, even millions, of dollars in capital savings for our customers Get the fundamentals here….. www.sme.org/uploadedFiles/Events/Webinars/layup_tooling.pdf Carbon fiber reinforced polymer (CRFP) tooling considerations Prepreg & Autoclave/Oven Cure Infusion & Oven Cure Pros Quality is less process-dependent Less complicated process Better dimensional control with masters Lower cost material Longer “out time” Can use less expensive foam masters Cons Shorter out time More expensive masters Higher cost material Process-dependent quality Process is more complicated More challenging dimensional control with foam masters Some options Cytec Cycom LTM Airtech Toolmaster, Beta Airtech Toolfusion PTM&W (various options) Out-of-Autoclave M&P is good, but what about manufacturing really large, high Tg structures? Launch Vehicle Structure Design Concept Size Dia x length (m) Atlas V Interstage GrEp/Al core 3.8 x 4.5 Fairing GrEp/Al core 5.4 x 26.5 Interstage GrEp/Foam core 5.1 x 6.5 Fairing GrEp/Foam core 5.1 x 19.8 Interstage GrEp/Al core - Fairing GrEp/Al core 5.4 x 17.0 Interstage GrEp/Al core 10.0 x 14.5 Fairing GrEp/Al core 10.0 x 22.0 Delta IV Arianne V Ares V Shuart, M. SME Composite Manufacturing 2010 Increasing Diameter Processing technology suite – not just a new resin system • Proprietary two-part epoxy • Commercially available master materials Aerospace-grade composite (not toughened) • >390°F Tg (defined at onset of softening in storage modulus) • >55% fiber volume (<0.5% voids) • Comparable to Cycom 5215 (CAI, OHT, OHC, SBS, in-plane shear) • Demonstrated with aluminum honeycomb core Infusion process • Viscosity <500 cPs at room temperature • Pot life ~1 to 2 hrs • Opportunities for future research with prepreg or uni tape format No heat added • No heat input of any kind (cure is self-generated) • No post-cure required • 95-98% degree of cure in 1 to 2 hours (typical) • 1 to 4-hour cool-down period Fiber volume typically 54-58% Void content less than 0.5% Demonstrated curved surfaces Carbon and glass Varying thickness • Thinnest: 4 plies (0.05") • Thickest: 288 plies (~2") • Can infuse with open cell core Varying area • Smallest: 4" x 4" • Largest: 50 ft2 Foam Tool Layup Resin Infusion Self-Curing NONA process features: Fewer steps Lower cost tooling board Quicker cure Benefits: Cost and time savings De-mold Tool/ Part Take away: Vitrification Tgel = 69 °C (tanδ = 1) Tvitrification = 92 °C (onset η*) Part has locked in shape before tool heats up (and tries to change dimension) Tools for NASA 1/10th scale 8.4m diameter SLS Fairing petal – ¼ section of ogive and upper barrel • 84cm diameter upper barrel, 2m length Nose cap • 25cm diameter, 7cm height • FR-4718 foam master (General Plastics) • Duratec coating (Hawkeye Industries) • 28 ply, quasi-isotropic layup, 3k 2x2 twill • Bagged to steel plate • NONA Composites RT-177 resin • Room temp infusion, ~45 min • Max temps – 120 ºC – 180 ºC (60 ºC delta) • Max temp avg 158 ºC +/- 15 ºC • Time between max temps – 30 min • Nose and tail cured 20-30 min after majority of part had vitrified • Cracking of master surface during demold (thermal shock) • Visible porosity & failed leak check • Secure master to substructure • Tooltec (Airtech) on repaired Duratec surface • Facesheet edge protection • Heavier carbon fabric – 12K, 2/2 twill • Divergent resin flow setup • Improved insulation • Dimensional tolerance measurement • Max temps – 151 ºC – 169 ºC (18 ºC delta) • Max temp avg 163 ºC +/- 4 ºC • Time between max temps – 12 min • Good overall wetout • Some fabric wrinkles • Overall thickness 0.96 cm (0.38 in.) • Leak rate 0.46 torr/min (0.018 in Hg/min) NONA Composites trial 4 ply infused part – vacuum only, 350 F cure Good surface, no leakage NASA MSFC trials Prepreg cauls – 80 psi, 350 F cycle (3x) Core part – 40 psi, 350F cycle Good surfaces, no leakage. Oven-cycled compared to as-fabricated Hand benching, multiple oven and autoclave cycles and transportation compared to as-fabricated -0.008 in to 0.006 in across the part area (average absolute deviation of 0.003 in) -0.001 in to 0.004 in across the part area (average absolute deviation of 0.002 in) • • • • • • Machines well with diamond based cutters Cooling fluid recommended Follow standard carbon composite machining best practices Compatible with standard polished surfacing options Spring-in compensation for material cure and master effects during cure Approximately 0.5 degrees spring-in compensation calculated for 0.42m dia arc segment Customer proprietary Small tool - ~0.17 ft2 NASA SLS 1/10th scale ogive petal tool - ~50 ft2 12 Tool for OOA epoxy 10 Industry standard acceptable leak rate* Tool for Autoclave BMI Leak rate (Pa/sec) 8 Take away: 6 NONA process maintains vacuum integrity through >60 part build cycles 4 2 0 0 10 20 30 40 Number of parts *MTM 45-1 Tech Sheet recommends <2 in Hg per 10 min (11.3 Pa/sec) 50 60 Tool surface baseline 64 epoxy parts oven cured on NONA tool MTM45-1 / AS4-GP-145 OoA epoxy prepreg Oven cycle 130˚C for 2 hours, 180˚C for 2 hours 19 BMI parts autoclave cured on NONA tool CycomTM 5250-4 / AS4-3K-70PW 121˚C /15 psi/45 min and 177˚C /100 psi/180 min Tool surface after Part 59 • Vacuum integrity maintained • Surface roughness: Ra < 0.5 μm and Rz < 2.0 μm for both tools System Master Cost ($/ft2) Material ($/ft2) Consumables ($/ft2) Oven/Autoclave Op Cost Labor cost ($/ft2) Total Cost ($/ft2) Fabrication time LTM Prepreg Autoclave cure 100% 100% 100% 100% 100% 100% 100% Toolfusion3 Oven cure 85% 34% 113% 20% 100% 79% 100% PTM&W Oven cure 85% 28% 113% 40% 120% 86% 167% NONA RT-177 93% 55% 125% 0% 89% 79% 67% All options have pros and cons NONA resin and processing is a good option for the tooling engineer But…..NONA’s real benefit is in the flexibility it delivers Are you one of these people? I machine masters and want to make composites but I don’t have an oven or autoclave… …So with this I can learn infusion and now make composites in my shop without additional capital investment …Or, maybe a NONA team can come to my shop, make the part on the master I machined, and then leave I have an oven/autoclave already but they’re always tied up for production….. …So I like this as an option for making parts off to the side I currently do infusion but the curing process takes too long… …So with this I can get quicker turn time on my molds My oven is my single biggest bottleneck… …So with this I can manufacture in parallel lines or even in the field I just installed a large oven/autoclave and now we are being asked to bid a slightly bigger part….. …So I’d like to never deal with this situation again! Top 10 Failed NONA Slogans 10. No shirt, no shoes, no oven, no autoclave, no problem 9. I got 99 problems but an oven ain’t one 8. NONA means NONA 7. There’s no business like NONA business 6. Bravely charging into the un-NONA 5. NONA….definitely not NANO 4. Autoclaves – Ain’t nobody got time for that! 3. No oven, no autoclave, no you didn’t! 2. NONA, No Doubt 1. You’ve lost that oven heating…woa that oven heating. You ‘ve lost that oven heating now it’s gone, gone, gone……… NO-O-O-O-NA