R- Value Evaluation

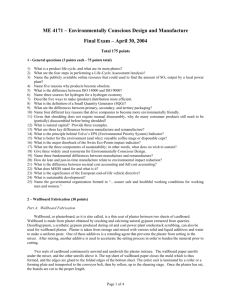

advertisement

Experimental Wallboard: R-Value Validation Paul Gollnick Dave Garrett Will Watson 8/13/07 Overview Objective Test 1- Conduction apparatus Test 2- Tube Test Test 3- Hot Plate Recommendations Conclusion Objective 1. Wallboard Testing: The purpose of this series of experiments was to determine the heat transfer coefficient and associated R-value for standard ½” composite wallboard 2. Group: Our objective was to evaluate the problems associated with testing and suggest a more appropriate test method Test 1: Conduction Apparatus Set Up #1 Set Up #2 Set Up #1 Data Power 2.25 W 3.15 W 6.35 W 10.7 W ED#2 D#2 E.D#1 D#1 E.D#3 D#3 E.D#4 D#4 T1 47.51 45.7 54.1 55.6 84.4 83.96 118.8 120.47 T2 47.09 45.2 53.3 55.2 83.3 82.81 117.2 118.48 T3 46.36 44.5 52.3 54.2 82.4 81.87 115.9 118.48 T7 24.8 24.2 23.6 24.7 25.7 27.29 27.7 29.66 T8 24.8 24.2 23.5 24.6 25.6 27.18 27.4 29.54 T9 24.8 24.2 23.4 24.6 25.6 27.18 27.3 29.54 Temperature with Respect to Power: Experimental Wallboard vs. Standard Wallboard 120 100 Temperature (c) 80 2.5 W E.D 2.5 W D 3.15 W E.D 3.15 W D 6.35 W E.D 60 6.35 W D 10.7 W E.D 10.7 W D 40 20 0 T1 T2 T3 T7 Temperature Probe T8 T9 Test #1 Analysis g (Ts T ) D 3 Ra D 1/ 6 0.387 Ra D Nu D 0.6 9 / 16 1 0.559 / Pr h Nu D k D qconv h As (T7 T3 ) qrad A (Ts Tsur ) 4 q3 q1 qconv qrad k q3 L (T3 T7 ) A 4 8 / 27 2 Test #2 Data Power 6.2 W 6.2 W 10 W 15.1 W 6.15 W 9.85 W 13.45 W E.D#1 E.D#2 E.D#3 E.D#4 D#1 D#2 D#3 T1 66.8 68.7 95.5 115.5 76.2 104.5 123.8 T2 66.8 68.3 93.1 115.3 75.1 103.7 124.4 T3 65.5 67.9 92.5 114.1 71.8 99.2 119.2 T7 32.1 34.7 41.9 48.5 30.4 33.4 34.7 T8 31.8 34.4 41.4 47.8 30.2 33 34.2 T9 31.7 34.3 41.2 47.4 30.1 32.8 34.1 Temperature along Heat Path 140 120 100 Temperature (C) 6.2 80 6.2 10 15.1 6.15 60 9.85 13.45 40 20 0 1 2 3 4 Thermocouple location 5 6 Test # 2 Analysis q3 q1 k q3 L (T3 T7 ) A Test 2: Tube Test Thermal Conductivity Comparison: ACTR Wallboard vs. Standard 350 300 Temperature (C) 250 200 Standard Hot Standard Cold ACTR Hot ACTR Cold 150 100 50 0 0:00:00 0:15:00 0:30:00 0:45:00 1:00:00 1:15:00 Tim e (m in) 1:30:00 1:45:00 2:00:00 2:15:00 Test 3: Hot Plate Figure 3: Hot Plate Test Results for Standard Drywall and ACTR Wallboard 80 70 Temperature (C) 60 50 40 30 20 10 0 0:00 0:30 1:00 1:30 2:00 Time (hr:min) Standard Drywall #1 Standard Drywall #2 Standard Drywall #3 ACTR Wallboard #1 ACTR Wallboard #2 ACTR Wallboard #3 2:30 Hot Plate Analysis q" k al (Ti Tsi ) Tsi Tso q" L p1 Lx L p 2 k p kx kp Recommendations Perform test #1 run #1 with aluminum foil and or saran wrap enclosed in duct tape to trap dead air space as an insulator When running test #1 use lube to eliminate contact resistance Consider the time it takes to reach steady state, not just what happens at steady state Make boxes of the material and fill them with ice to test which one lasts longest Try different thicknesses of the material and run it without the paper Conclusion Objective Test 1- Conduction apparatus Test 2- Tube Test Test 3- Hot Plate Recommendations Conclusion