Lecture 22-Script

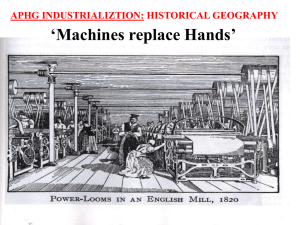

advertisement

Lecture 22 41. New Technology in Manufacturing MAE364 Manufacturing Processes Spring 2005 Instructor: T. Kesavadas (Prof. Kesh) Associate Professor, Mechanical and Aerospace Engineering, 1006 Furnas Hall. http://wings.buffalo.edu/courses/sp04/mae/364/ Teaching Assistants (more details later): Govindarajan Srimathveeravalli Sridhar Seshadri What is Manufacturing? Manu Factus : Latin for ‘made by hand’ Definition: A Well organized method of converting raw material to end product End Product: Value and utility added to output. Manufacturing Process History of Manufacturing • Manufacturing started during 5000 – 4000 BC Wood work,ceramics,stone and metal work • Steel Production 600-800 AD • Industrial Revolution 1750 AD: Machine tools run by invention of steam engine • Mass Production and Interchangeable Parts • Computer Controlled Machines 1965 • CNC,FMS systems Historical development of materials - The Early Days Egypt ~3100 B.C. to ~ 300 B.C Greece ~1100 B.C. to ~146 B.C Roman Empire ~500 B.C. to 476 A.D Middle Ages 476 to 1492 Renaissance 14th to 16th centuries Period Metals and Casting Forming Process Before 4000 B.C Gold,copper and meteoritic iron Hammering 4000-3000 B.C. Copper casting,stone and metal molds,lost wax process,silver,lead,tin,bron ze Stamping Jewelry 3000-2000 B.C. Bronze casting Wire by cutting and drawing, gold leaf 2000-1000 B.C. Wrought iron,brass 1000-1 B.C. Cast iron, cast steel Stamping of coins 1A.D – 1000 A.D Zinc steel Armor,coinage,for ging steel swords 1000-1500 A.D. Blast furnace, type metals,casting of bells,pewter Wire drawing,gold silver smith work Historical development of materials - The Industrial Revolution Industrial Revolution 1750-1850 1500-1600 A.D. Cast iron cannon, tinplate Water power for metal working,rolling mill for coinage 1600-1700 A.D. Permanent mold casting,brass from copper and metallic zinc Rolling(lead,gold,silver ) Shape rolling(lead) 1700-1800 A.D. Malleable cast iron,crucible steel Extrusion (lead pipe), deep drawing, rolling(iron bars and rods) 1800-1900 A.D. Centrifugal casting,Bessemer process,electrolytic aluminum,nickel steels,Babbitt, galvanized steel, powder metallurgy, tungsten steel, open hearth steel Steam hammer, steel rolling,seamless tube piercing,steel rail rolling, continuous rolling , electroplating Historical development of materials - The Modern Age WW I and WW II Space Age 1900-1920 A.D. Tube rolling, hot extrusion 1920-1940 A.D. Die casting Tungsten wire from powder 1940-1950 A.D. Lost wax for engineering parts Extrusion (steel),swaging, powder metal for engineering parts 1950-1960 A.D. Ceramic mold, nodular iron, semiconductors,continuou s casting Cold extrusion (steel),explosive forming,thermo mechanical treatment 1960-1970 A.D Squeeze casting, single crystal turbine blades Hydrostatic extrusion,electroforming 1970-1980 s Compacted graphite,vacuum casting,organically bonded sand,automation of molding and pouring, large aluminum castings for aircraft structures rapid solidification technology Precision forging,isothermal forging, super plastic forming,die design by analytical methods, net shape forming Req. for a good manufacturing system Requirements of a good manufacturing system • • • • • Product should meet design requirement Economical Process Quality should be built into the system Should be flexible and responsive to new technology High productivity: Best utilization of man, material, machine, capital and available resources. Steps in Modern Manufacturing Definition of product need, marketing information Design analysis;codes/standards review; physical and analytical models Conceptual design and CAM and CAPP Production evaluation Feasibility study Prototype production testing and evaluation Inspection and quality assurance CAD Production drawings; Instruction manuals Material Specification; process and equipment selection; safety review Pilot Production Packaging; marketing and sales literature Product Manufacturing of a Paper Clip • • • • What is the function How long does it last How critical is the part Material • Dimension • Method of manufacturing • Function based design • Style Metallic - what type Non metallic – plastic Diameter of clip Shape of clip Manual Automated Stress, Strain Life of clip Stiffness Appearance,Color,Finish Plating,painting AISI 1010 welded tubing, assembly resistance welded and electrostatically painted Manufacturing of a bicycle Aluminum alloy forging, polished and buffed Forged aluminum tubing(alloy similar to 6063), polished and buffed AISI 1010,swaged and cadmium plated AISI 1008,press formed resistance welded and painted AISI 1020,forging and chromium plated AISI 1010, luster finished AISI 1008, press coil stock,profile formed,welded and plated milled,resistance welded and chromium plated formed,welded and plated Cold drawn medium carbon steel,( similar to AISI 1035) bright zinc plated AISI 1020 tubing, machine threaded and painted AISI 1010,stamped and coined and chromium plated AISI 1010, stamped and chromium plated Seamless AISI 1020 tubing swaged tube sections brazed into fork crown,painted Headed brass,nickel plated Aluminum permanent mold casting,machined , polished Hardened high-carbon and buffed steel,thread rolled and chromium plated AISI 1010,stamped and chromium plated AISI 1040 forging,carburized and chromium plated Case hardened forging quality steel parts, black oxide coating Assignment 1 • Select a simple product of your choice – Try to analyze the different materials, processes, etc – Use library resources – We will discuss this in the class on Friday Selection of Process: Topic to be covered Casting • Sand/Expandable Mold,Permanent Mold Forming and Shaping • Rolling,forging,extrusion,powder metallurgy Machining • Turning,Boring,Drilling,Milling,Planing,Broaching,Grin ding Selection of Process Unconventional Method • EDM,ECM,Ultrasound,High Energy Beam,machining Joining • Welding,Brazing,Soldering Finishing • Honing,Lapping,Polishing,Burnishing,Deburring Objectives of this course and what is expected of you • Manufacturing processes and fundamentals • Selection of appropriate process to meet design requirements • Effect of process parameters and variables on the quality of parts produced • Effect of material properties on a given process • Decision and methods for different product size and mix • Effect of design on manufacturability • Overview of computer aided methods in traditional manufacturing processes Two methods of forming a dish shaped part from sheet metal Left: conventional hydraulic/mechanical press using male and female dies Right: explosive forming using only one die. pressure Upper die Explosive water work piece Lower Die Three methods of casting turbine blades A: conventional casting with ceramic mold B: directional solidification C: Method to produce single crystal blade Selection of Process depends on • • • • Dimensional and surface finish requirements Operational Cost Design and strength requirements Consequences of various methods Design for Assembly • Design of the product to permit assembly • Possibility of multipurpose parts • Capability of manufacturing process to consistently produce parts which can be assembled without problem • Method or process of assembly Automated Systems,Manual Systems etc Design for Assembly Automation and Impact of Computers Machine Control Systems Computer Numerical Control machines, Robots,Machines,Processes Computer Integrated Technology • Responsive to market change • Better use of process,man,machining management etc • CAD/CAM: Computer Aided Design And Manufacturing • FMS: Flexible Manufacturing System • GT: Group Technology • VR: Virtual Reality Applied Manufacturing GCSE Enterprise elements to enhance understanding UNIT 3 Applications of Technology 25 Applied Manufacturing GCSE Unit 3 Aim of the Unit:- To investigate the impact of modern technology on the design and manufacture of a range of products 26 Applied Manufacturing GCSE Unit 3 • • • • • • Modern technology, includes….. Production implications Cost implications Human resource implications Socio-economic implications Demographic implications 27 Applied Manufacturing GCSE Unit 3 You will learn how:• New technology has helped to develop design and manufacturing processes • New technology has improved the quality of products and services offered to customers 28 Applied Manufacturing GCSE Unit 3 You will investigate:• Information and communications technology • New components and a range of modern materials including smart materials • Control technology 29 The use of I.C.T.includes • Sourcing and handling information and data, such as databases, spreadsheets and internet sites • CAD (computer-aided design) techniques • CAM (computer-aided manufacture) • Communications technology • Control technology 30 Use of Modern and Smart Materials and Components including:• Polymers, inc plastics, adhesives and coatings • Metals and composites • Biological, chemical and food products, modified ingredients and methods of preparation and production • Computer technology, inc microprocessors • Micro-electronic components • Textile technology, inc liquid crystal, coated fabrics and thermochromic dyes 31 The use of systems and control technology:• To organise, monitor and control production including:• Process/quality control and automation, inc PLCs • Robotics, including continuous operation, increased speed, etc • ICT as applied to integrated manufacturing/engineering systems, etc 32 The impact of modern technology. • • • • Range, types and availability of products Design and development of products Materials, components and ingredients Safety and efficiency of modern methods of production • Improved characteristics of products, e.g. size, weight/density, ease of use, disposability and reclaimability • Markets for the products 33 Advantages and Disadvantages of Modern Technology • Changes in the type and size of workforce (social implications) • Changes in the working environment • Impact on the global environment and sustainability 34 Investigating Products • Your teacher has gathered together a number of examples of the same product (*as appropriate to the course) • These products have either been produced at different times, for different purposes, within a price band, for use in different environments, etc • Examine each and record as much information you can derive and then compare with the accompanying checklist (* these should be obtained/produced locally wherever possible) 35 Considerations • The role modern technology plays in the design and manufacture of the product • The technology or process it replaced • The benefits of using the technology • The implications of using the technology, for the product and the manufacturer 36 Visit to modern manufacturing base • You will be visiting Company “ABC” • This company operates primarily using modern technology • You will need to refer to the worksheet. “Visit to a modern manufacturing facility” to decide what questions you need to ask on the visit • Discuss with your teacher and other class members 37 How does the product work? In terms of its:• • • • Purpose Structure and form Materials and components Technology used 38 Further considerations • Should manufacturers continue to develop and adopt new technologies? • Should manufacturers continue to improve their products? • Should they consider the workforce and the social implications of advancement brought about by technological advancement? • How much should they consider global implications of this advancement? 39 NCP Info Day 13 May 2011, Brussels Factories of the Future & Next ICT Calls Dr Erastos Filos FoF ICT Coordinator NCPs-InfoDay_13May11 Factories of the Future (FoF): Context • What: – Part of the Recovery Plan – To help manufacturing, in particular SMEs, across a broad range of sectors be competitive after the Crisis is over • How: – Industry-driven R&D projects – 4 annual co-ordinated calls until 2013 between the two relevant FP7 Themes, ICT and NMP • Who: – R&D stakeholders of European Technology Platforms ARTEMIS, ENIAC, EPOSS, EUROP, NESSI, PHOTONICS21, MANUFUTURE – Technology providers & industrial users (large & SME), academic researchers • Total FP7 budget (2010-2013): – 245 M€ (ICT) + 400 M€ (NMP) NCPs-InfoDay_13May11 State of the Industry & Expected Impact • Europe’s manufacturing – – – – – – More than 25 sectors, 21 % of GDP (= € 6.5 trillion), 30+ million jobs Crisis has reduced Europe’s production capacity Export champions (but at risk) in machinery, automobiles, wind turbines, … Largest global market share in automation & factory equipment Under threat from low wage economies (eg mass-produced goods) Chance to compete through high added-value products (eg quality, services, customisation, clean & energy efficient processes) • FoF ICT: Technology leaders to gain market share – – – Automation/industrial robotics & laser technology solutions for factory environments Product/production design tools (eg software for modelling, simulation, visualisation) Software for enterprise/supply-chain management • FoF ICT: European industrial end users to – – – Integrate latest technology into their production environments Build on new competencies (knowledge, organisation, skills, business models) Use technologies that enable energy-efficient and “waste-less” production NCPs-InfoDay_13May11 Recovery Plan Objectives: Industrial Competitiveness Supply side Technology/manufacturing equipment suppliers to gain market share: • Automation/industrial robotics & laser technology solutions for factory environments • Product/production design tools (eg software for modelling, simulation, visualisation) • Demand side • • • Enterprise/supply-chain management tools ICT European industrial end users: To integrate latest technology into their production environments To develop new competencies (knowledge, organisation, skills, business models) To use technologies that enable energy-efficient and “waste-less” production NCPs-InfoDay_13May11 Factories of the Future ICT Vision Smart Factories: – – Goal: More automation, better control & optimisation of factory processes Means: Software, lasers & intelligent devices embedded in machines & factory infrastructure Virtual Factories: Sensors, Tags data PLM server Product info data info advice PLM agent (reader) Info request – Goal: To manage supply chains; to create value by integrating products & services – Means: Software to holistically interconnect & manage distributed factory assets; new business models & value propositions Digital Factories: – Goal: To “see” the product before it is produced – Means: Software for the digital representation & test of products & processes prior to their manufacture & use NCPs-InfoDay_13May11 Factory productivity • Less waste • Less energy use • Faster time-to-market • Better quality Supply-chain productivity • High-value products • Keep jobs in Europe • Process transparency • IPR security • Lower CO2 footprint Design productivity • Reduce design errors • Better & efficient products • Less waste + rework • Faster time-to-market 2009 FoF ICT Call on “Smart Factories”: Manufacture of Successful Proposals sustainable products Economic efficiency/ productivity (a): Process automation & optimisation (b): ICT & sensors for energy efficiency (c): Robotics-enabled TAPAS production CustomPacker (d): Laser applications ActionPlant RoboFoot FoFdation PlantCockpit KAP FoF-ICT-WP2011-12_ICT2010_29Sep10 Energy efficiency A.K 09 2010 FoF ICT Call - Virtual Factories Work Programme coverage Target outcomes a b c d Main theme ADVENTURE X Factory process optimisation BIVEE X Business innovation COMVANTAGE (IP) X EPES X Extreme Factories X GloNet X IMAGINE (IP) X X MSE (IP) X X PREMANUS VENIS Dynamic composition of services Industrial SME innovation X Cloud-based networks of SMEs X X Integrated management of networked manufacturing X X Distributed, autonomous, interoperable innovation ecosystems of manufacturing assets X X Product-centric collaboration Re-manufacturing X Large enterprise/SME interoperability 2010 FoF ICT Call - Digital Factories Work Programme coverage Objective FoF-ICT-2011.7.4 a) b) c) Comprehensive engineering platforms (IP, STREP) Simulation & virtual prototyping tools for product/process design (IP, STREP) Holistic modelling & simulation of full complex Products / processes (IP, STREP, CSA) Retained Proposals RLW Navigator I-Conik (IP) amePLM LinkkME (IP) Vistra Simposium (IP) Terrific FFD Simposium (IP) Issues covered Issues not covered All All Digital evaluation & simulation of material properties - from microto macro-scale Digital modeling and simulation of product & process behaviour Results of first FoF ICT+NMP Calls July 2009 • Success rate: 26% July 2010 19% (25 funded of 98) (36 funded of 193) • Share by Org. Type: - Higher Education: - Private for Profit: - Research Org.: • Share of funding of SMEs: partners: 23% 54% 50% 22% 31% • Countries of funded 25 NCPs-InfoDay_13May11 24% 24% 29% 26 Factories of the Future 2011 Call Expected impact & conclusions “Digital Factories” “Virtual Factories” – Higher management efficiency of networked & sustainable business operations. – ICT tools enabling the participation of SMEs in virtual factory environments. – New business models & innovation scenarios for a low-carbon economy. – – - Attractive to industry • 8 projects Smart Factories 2011 Call Accelerated product design & manufacturing, with a considerably shorter time-to-production & time-tomarket FoF is: • 35 M€ Virtual Factories Scaling and higher accuracy of digital design tools & simulation techniques – 2010 Call ICT Reinforced European leadership in knowledge-driven platforms & tools for product development & manufacturing - SME-friendly - Of shorter term scope Digital Factories 2011 Call • 45 M€ • 35 M€ • 10 projects • 8 projects Factories of the Future Multi-Annual Roadmap 20102013 Sub-Domains: 1. Sustainable Manufacturing 2. ICT-enabled intelligent manufacturing 3. High-performance manufacturing 4. Exploiting new materials through manufacturing http://ec.europa.eu/research/industrial_technologies/pdf/ppp-factories-of-the-futurestrategic-multiannual-roadmap-info-day_en.pdf NCPs-InfoDay_13May11 Factories of the Future Beyond 2013? 2009 2010 2011 2012 2013 FP8 proposal end ’11 FP8 launch early ’13 MAFF Jun ’11 2009 2010 Virtual Factories 2012 2011 Digital Factories (45 M€) Smart Factories July ’09 – Nov. ‘09 FP7 Calls FoF Call 9 July – 2 Dec 2010 70 M€ (35 M€) Smart Factories Manuf. solutions for new ICT products Obj. 7.1 (40 M€) Obj. 7.2 (20 M€) NCPs-InfoDay_13May11 Jul – Dec 2011 Policies Total ICT 245 M€ The double role of ICT Smart Factories Obj. 7.1 Virtual Factories Obj. 7.3 Towards Future ICT Factories … Digital Factories Obj. 7.4 “Manufacturing Solutions for new ICT“ Factories of the Future Obj. 7.2 NCPs-InfoDay_13May11 Objective 7.1: Smart Factories Energy-aware, agile manufacturing & customisation Where do we stand? • • • • EU: Global leader in automation, industrial robotics & laser systems Key industry players: ABB, Siemens, Festo, Schneider Electric, Acciona, Bosch, KUKA, COMAU, Trumpf, … EU position: Increasingly threatened by Japan, USA, Korea, China Lack of standardisation NCPs-InfoDay_13May11 What do we want to achieve & why? • • • Maintain & extend Europe’s 30% market share: «Factories» as products Strong, export-oriented sector needs to maintain competitiveness Tackle resource use efficiency of manufacturing (especially reduce 25% share of energy consumption) • Open new markets for innovative ICT devices & automation systems Objective 7.1: Smart Factories Energy-aware, agile manufacturing & customisation Target outcomes a) Demonstration, benchmarking of process automation & control – – For discrete, continuous or batch industries Key features: flexibility, autonomy, robustness, energy transparency – Demonstration in real industrial environments b) Large-scale validation of advanced industrial robotics systems – User-friendly interaction with & tasking of intelligent cooperative robotic systems – Large-scale applicability to flexible, small batch & craft manufacturing c) Applications based on factory-wide networks of intelligent sensors, new metrology tools & methods – Real-time management of manufacturing information (incl. planning, scheduling, dispatching) d) Lasers & laser systems for manufacturing & materials processing – – High-brilliance diode lasers/laser arrays New wavelengths & online adaptation of beam properties Call FoF/2011 40 M€ NCPs-InfoDay_13May11 IPs/STREPs Objective 7.2 Manufacturing solutions for new ICT products Target outcomes • Primarily roll-to roll wet deposition, but also other processes, e.g. – • Evaporation, hot-embossing, laser processing, other low-temperature processes Tackle main roadblocks, e.g. – Patterning processes, resolution, registration accuracy, process stability, multilayer lamination, encapsulation, automation, in-line quality control, architectures to cut production costs Feasibility demonstrators • Standardisation issues as appropriate • Industry-driven, strong quality control, testing & validation elements Call FoF/2011 NCPs-InfoDay_13May11 20 M€ IPs Thank you Thank you FoF on the web: http://ec.europa.eu/research/industrial_technologies/l ists/factories-of-the-future_en.html PPP Information Event in Brussels, 9 July 2010 FoF Contacts: 7.1 Objective: erastos.filos@ec.europa.eu 7.2 Objective: christoph.helmrath@ec.europa.eu CHASE AQUILANO JACOBS Operations For Competitive Management Advantage Chapter 4 Process Analysis ninth edition Chapter 4 Process Analysis • Process Analysis • Process Flowcharting • Types of Processes • Process Performance Metrics Process Analysis Terms • Process: Is any part of an organization that takes inputs and transforms them into outputs. • Cycle Time: Is the average successive time between completions of successive units. • Utilization: Is the ratio of the time that a resource is actually activated relative to the time that it is available for use. Process Flowcharting Defined • Process flowcharting is the use of a diagram to present the major elements of a process. The basic elements can include tasks or operations, flows of materials or customers, decision points, and storage areas or queues. • It is an ideal methodology by which to begin analyzing a process. Flowchart Symbols Tasks or operations Decision Points Examples: Giving an admission ticket to a customer, installing a engine in a car, etc. Examples: How much change should be given to a customer, which wrench should be used, etc. Flowchart Symbols (Continued) Storage areas or queues Examples: Sheds, lines of people waiting for a service, etc. Flows of materials or customers Examples: Customers moving to the a seat, mechanic getting a tool, etc. Example: Flowchart of Student Going to School Go to school today? No Goof off Yes Drive to school Walk to class Multistage Process Stage 1 Stage 2 Stage 3 Multistage Process with Buffer Buffer Stage 1 Stage 2 Other Types of Processes • Make-to-order – Only activated in response to an actual order. – Both work-in-process and finished goods inventory kept to a minimum. • Make-to-stock – Process activated to meet expected or forecast demand. – Customer orders are served from target stocking level. Process Performance Metrics • Operation time = Setup time Run time • Throughput time = Average time for a unit to move through the system • Velocity = Throughput time Value-added time Process Performance Metrics (Continued) • Cycle time = Average time between completion of units • Throughput rate = 1 . Cycle time • Efficiency = Actual output Standard Output Process Performance Metrics (Continued) • Productivity = Output Input • Utilization = Time Activated Time Available Cycle Time Example • Suppose you had to produce 600 units in 80 hours to meet the demand requirements of a product. What is the cycle time to meet this demand requirement? • Answer: There are 4,800 minutes (60 minutes/hour x 80 hours) in 80 hours. So the average time between completions would have to be: Cycle time = 4,800/600 units = 8 minutes. • Process Throughput Time Reduction Perform activities in parallel. • Change the sequence of activities. • Reduce interruptions. Materials Properties of Materials Mechanical Properties: strength, toughness, ductility, hardness, elasticity, fatigue, creep. Behavior Under Loading: tension, compression, bending, torsion, shear. Physical Properties: density, specific heat, thermal expansion, thermal conductivity, melting point, electrical and magnetic properties. Chemical Properties: oxidation, corrosion, degradation, toxicity, flammability. Types of Materials Ferrous Metals: iron and steel. Nonferrous Metals and Alloys: aluminum, magnesium, copper, nickel, titanium, superalloys, beryllium, zirconium, low-melting alloys, precious metals. Plastics: thermoplastics, thermosets, elastomers. Ceramics: glass, graphite, diamond. Composite materials: reinforced plastics, metalmatrix and ceramic-matrix composites, honeycomb structures. Ferrous Metals: Applications • Structural: building structures, concrete reinforcement • Automotive: chassis, engine parts, drive train, body parts • Marine: ship hulls, structure, engines • Defense: tanks, weapons • Consumer Products: appliances, recreational vehicles, toys, utensils and tools Nonferrous Metals: Applications • Architectural: aluminum windows and doors • Automotive: aluminum engine blocks, copper wiring, mag wheels • Marine: brass/bronze fittings, bearings, propellers • Defense: brass shell casings • Consumer Products: electrical wiring, utensils, jewelry, electronics Plastics (Polymers) • Compared to metals, plastics have lower density, strength, elastic modulus, and thermal and electrical conductivity, and a higher coefficient of thermal expansion • The design of plastic parts should include considerations of their low strength and stiffness, and high thermal expansion and low resistance to temperature. Plastics: Applications • Architectural: electrical and thermal insulation, weather seals, carpets, wall coverings, paint • Aerospace: electrical and thermal insulation, instrument panels,upholstery, seals • Automotive: body panels, instrument panels, upholstery, electrical and thermal insulation, seals, hoses, tires • Consumer Products: toys, sporting goods, appliances, tools, utensils, clothing, shoes, packaging Manufacturing “The Process of Converting Raw Materials Into Products” Manufacturing a Product: General Considerations • Material Selection • Processing Methods • Final Shape and Appearance • Dimensional and Surface Finish • Economics of Tooling • Design Requirements • Safety and Environmental Concerns Choosing Methods of Production Use a Selection Chart Manufacturing Processes for Metals • Casting: expendable mold and permanent mold. • Forming and Shaping: rolling, forging, extrusion, drawing, sheet forming, powder metallurgy, molding • Machining: turning, boring, drilling, milling, planing, shaping, broaching, grinding, ultrasonic machining, chemical machining, electrical discharge machining (EDM), electrochemical machining, high-energy beam machining • Joining: welding, brazing, soldering, diffusion bonding, adhesive bonding, mechanical joining • Finishing: honing, lapping, polishing, burnishing, deburring, surface treating, coating, plating Casting Processes Introduction of molten metal into a mold cavity; upon solidification, metal conforms to the shape of the cavity. Die Casting Sand Casting Forming and Shaping Processes Bulk deformation processes that induce shape changes by plastic deformation under forces applied by tools and dies. Forging Extrusion Machining Processes Material removal from a work piece: cutting, grinding, nontraditional machining processes. Milling Lathe Machine NC Machine Tool and Controller NC Punch Press Machine Manufacturing Processes for Plastics • Plastics are shipped to manufacturing plants as pellets or powders and are melted just before the shaping process. Polymers melt at relatively low temperatures and are easy to handle. • Plastics can be molded and formed, as well as machined and joined, into many shapes with relative ease. Injection Molding of Plastics Selective Laser Sintering System Courtesy of the University of Texas Chapter 7 Process Management 91 Wisdom from Texas Instruments “Unless you change the process, why would you expect the results to change” 92 Scope of Process Management • Process Management: planning and administering the activities – design, control, and improvement – necessary to achieve a high level of performance • Four types of key processes – – – – Design processes Production/delivery processes Support processes Supplier processes 93 AT&T Process Management Principles Focus on end-to-end process Mindset of prevention and continuous improvement Everyone manages a process at some level and is a customer and a supplier • Customer needs drive the process • Corrective action focuses on root cause 94 Process simplification reduces errors • • • • Control vs. Improvement Out-of-control Controlled Improvement process New zone of control Time 95 Leading Practices (1 of 2) • Translate customer requirements and internal capabilities into product and service design requirements early in the process • Ensure that quality is built into products and services and use appropriate tools during development • Manage product development process to enhance communication, reduce time, and ensure quality • Define, document, and manage important production/delivery and support processes 96 Leading Practices (2 of 2) • Define performance requirements for suppliers and ensure that they are met • Control the quality and operational performance of key processes and use systematic methods to identify variations, determine root causes, and make corrections • Continuously improve processes to achieve better quality, cycle time, and overall operational performance • Innovate to achieve breakthrough performance using benchmarking and reengineering 97 Product Development Paradigms Traditional Approach • Design the product • Make the product • Sell the product • • • • • Deming’s Approach Design the product Make it with appropriate tests Put it on the market Conduct consumer research Redesign with improvements 98 Product Development Process Idea generation Concept development Product & process design Full-scale production Product introduction Market evaluation 99 Quality Engineering • System Design – Functional performance • Parameter Design – Nominal dimensions • Tolerance Design – Tolerances 100 Loss Functions Traditional View loss no loss loss nominal tolerance Taguchi’s View loss loss 101 Taguchi Loss Function Calculations L(x) = k(x - T)2 Example: Specification = .500 .020 Failure outside of the tolerance range costs $50 to repair. Thus, 50 = k(.020)2. Solving for k yields k = 125,000. The loss function is: L(x) = 125,000(x - .500)2 102 2 2 Design Objectives • Cost, Manufacturability, Quality, Public Concerns • Tools and Approaches – Design for Manufacturability – Design for Environment 103 Streamlining Product Development • Competitive need for rapid product development • Concurrent engineering - a process in which all major functions involved with bringing a product to market are continuously involved with the product development from conception through sales • Design reviews 104 House of Quality Interrelationships Customer requirement Technical requirements Voice of the priorities Relationship matrix customer Technical requirement priorities Competitive evaluation 105 Quality Function Deployment technical requirements component characteristics process operations quality plan 106 Motorola’s Approach to Process Design 1. 2. 3. 4. 5. 6. Identify the product or service Identify the customer Identify the supplier Identify the process Mistake-proof the process Develop measurements and control, and improvement goals. 107 Evaluating a Process • Are steps arranged in logical sequence? • Do all steps add value? Can some be eliminated or added? Can some be combined? Should some be reordered? • Are capacities in balance? • What skills, equipment, and tools are required at each step? • At which points might errors occur and how can they be corrected? • At which points should quality be measured? • What procedures should employees follow where customer interaction occurs? 108 Projects • Project initiation – direction, priorities, limitations, and constraints • Project plan – blueprint and resources needed • Execution – produce deliverables • Close out – evaluate customer satisfaction and provide learning for future projects 109 Basic Components of Services • Physical facilities, processes, and procedures • Employee behavior • Employee professional judgment 110 Key Service Dimensions Customer contact and interaction Labor intensity Customization 111 Control • The continuing process of evaluating process performance and taking corrective action when necessary • Components of control systems – Standard or goal – Means of measuring accomplishment – Comparison of results with the standard as a basis for corrective action A well-controlled system is predictable 112 After Action Review 1. 2. 3. 4. What was supposed to happen? What actually happened? Why was there a difference? What can we learn? 113 Supplier and Partnering Processes • Recognize the strategic importance of suppliers • Develop win-win relationships through partnerships • Establish trust through openness and honesty 114 Supplier Certification Systems • “Certified supplier” – one that, after extensive investigation, is found to supply material of such quality that routine testing on each lot received is unnecessary 115 Benefits of Effective Supplier Process Management • • • • • Reduced costs Faster time to market Increased access to technology Reduced supplier risk Improved quality 116 Process Improvement • Productivity improvement • Work simplification • Planned methods change • • • • Kaizen Stretch goals Benchmarking Reengineering Traditional Industrial Engineering New approaches from the total quality movement 117 Kaizen • Gradual and orderly continuous improvement • Minimal financial investment • Involvement of all employees • Exploit the knowledge and experience of workers 118 Agility • Flexibility – the ability to adapt quickly and effectively to changing requirements • Cycle time – the time it takes to accomplish one cycle of a process • Benefits – Improve customer response – Force process streamlining and simplification 119 Breakthrough Improvement • Discontinuous change resulting from innovative and creative thinking • Benchmarking – the search of industry best practices that lead to superior performance – Competitive benchmarking – Process benchmarking – Strategic benchmarking • Reengineering – radical redesign of processes 120 Process Management in the Baldrige Award Criteria The Process Management Category examines the key aspects of an organization’s process management, including customer-focused design, product and service delivery, key business, and support processes. This Category encompasses all key processes and all work units. 6.1 Product and Service Processes a. Design Processes b. Production/Delivery Processes 6.2 Business Processes 6.3 Support Processes 121