Presentation_2_27_06 - Mechanical Engineering

advertisement

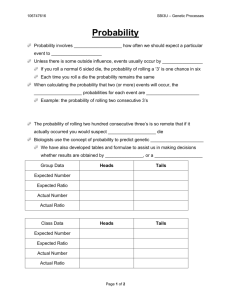

Group 8 – Chapters 13 and 14 •Jason Becker •Andrew Nawrocki •Ryan Niehaus •Jonathan Ogaldez •Stephen Wakeland Chapter 13 •Rolling of Metals Introduction • Movie Introduction • Rolling – The process of reducing the thickness or changing the cross-section of a long workpiece by compressive forces applied through a set of rolls – Not just for metal • Used to enhance plastics, powder metals, ceramic slurry, and hot glass Introduction Introduction • First step – Generally an ingot or continuous cast metal is "hot" rolled at elevated temperatures • Enhances material hardness and strength • "Cold" rolling – The material can be rolled at room temperature • Enhances strength, hardness, and surface finish • Requires more energy Introduction • Plates – Thickness of >6mm • Structural applications – Ship hulls, boilers, bridges, machinery, and nuclear vessels • Sheets – Thickness of <6mm • Typically provided as coils or flat sheets • Large variety of applications Flat-Rolling Process • Roll gap, L – Where reduction occurs • Relative sliding – To the right of the no-slip point, material moves faster than the roll – To the left of the no-slip point, material moves slower than the roll Flat-Rolling Process • Draft – Difference between the initial and final strip thicknesses (ho – hf) • Frictional Forces – Required to move workpiece – Must be overcome, increasing rolling forces and power requirements Flat-Rolling Process • Roll force – Lateral force required to compress the workpiece – Perpendicular to the plane of the strip Flat-Rolling Process • Reducing roll force – Reducing friction – Using smaller-diameter rolls – Taking smaller reductions-per-pass – Rolling at elevated temperatures – Applying tensions to the strip Flat-Rolling Process • Tension (Longitudinal Force) – Back tension • Force applied to the strip at the entry zone • Apply a braking action to the reel supplying the sheet into the roll gap (pay-off reel) – Front tension • Force applied to the strip at the exit zone • Applied by increasing the rotational speed of the reel receiving the sheet from the roll gap (take-up reel) Flat-Rolling Process • Geometric considerations – Due to roll forces, rolls may bend (deflection) • Causes the rolled strip to be thicker at its center than at its edges (crown) • Corrected for by making the rolls larger diameter at their center (camber) • To counteract deflection, the rolls can also be externally bent at their bearings Flat-Rolling Process Flat-Rolling Process • Spreading – Strips with a more square cross-section will cause its width to increase significantly during rolling – Increases with: • A decrease of width-to-thickness ratio • Increase of friction • Decrease of ratio of the roll radius to the strip thickness Flat-Rolling Process • Vibration and chatter – Have significant effects on product quality and productivity of metalworking operations – Chatter • Self-excited vibration • Can occur in rolling, extrusion, drawing, machining and grinding • Leads to periodic variations in the thickness of the sheet and its surface finish • Rolling speed and lubrication are the two most important parameters Flat-Rolling Practice • Initial Hot Rolling – Cast structure includes coarse and nonuniform grains – Hot rolling converts this to a wrought structure with finer grains and enhanced ductility Flat-Rolling Practice Flat-Rolling Practice • First hot-rolling product – Slab • Large rectangular cross-section – Bloom • Large square cross-section – Billet • Square cross-section smaller than a bloom Flat-Rolling Practice Flat-Rolling Practice • Conditioning – Surface of the slab, bloom, or billet must be prepared for subsequent rolling • Torch (scarfing) to remove heavy scale • Rough grinding to smoothen surfaces – Prior to cold rolling • "Pickling" with acid (acid etching) • Blasting with water • Grinding Flat-Rolling Practice • Cold rolling – Carried out at room temperature – Produces sheets and strips with: • Better surface finishes (lack of scale) • Better dimensional tolerances • Better mechanical properties • Pack rolling – Two or more layers of metal are rolled together to improve productivity – Aluminum Foil Flat-Rolling Practice • Defects – Adversely affect strength, formability, and other manufacturing characteristics – Wavy edges (a) • Result from roll bending and is thinner along its edges than at its center – Cracks (b & c) • Usually result from poor material ductility – Alligatoring (d) • Typically caused by defects in the original cast material Flat-Rolling Practice Flat-Rolling Practice • Other characteristics – Residual stresses • Small-diameter rolls tend to deform the metal more at its surface than in its bulk • Large-diameter rolls tend to deform the metal more in its bulk than at its surface Flat-Rolling Practice • Other characteristics (cont'd) – Dimensional tolerances • Thickness tolerances for cold-rolled sheets are more stringent than for hot-rolled sheets • Due to thermal effects, the final thickness of hot-rolled sheets is more difficult to predict – Surface roughness • Hot-rolled sheets are likely to require finishing operations, while cold-rolled sheets likely are not – Gage numbers • Smaller number = thicker sheet Section 13.4 Rolling Mills Hot Rolling Cold Rolling Types of Mills Materials Lubricants Types of Mills • Two-High Rolling Mills • Three-High Rolling Mills • Four High Rolling Mills • Cluster Mills • Tandem Rolling Two-High Mills • Used for hot rolling in the initial passes • Used on cast ingots • Used in continuous casting • Roll diameters .06m-1.4m Three-High Mills • Aka reversing mills • Plate or material being rolled will be raised and lowered throughout the machine from upper to lower roll gaps. Four-High Mills • Same principles as cluster mills, Sendzimir mills or Z mills • Utilize smaller rolls for lower roll forces • Also lower power requirements and reduce spreading • Rolls are cheaper to replace • Small rolls deflect more so they must be supported by smaller rolls • Very adept for cold rolling thin sheets high-strength materials Four-High Rolling Mill Cluster, Sendzimir or Z mill Tandem Rolling • Strip of Material continuously rolled through several stands • Gauges of stands get smaller progressively • Each stand (train) has its own rolls • Requires highly automated systems to control thickness and speed Tandem Rolling Mill Rolls • Rolls must be made of materials with high strength and resistance to wear • Common materials include cast iron, cast steel and forged steel • Forged steel has higher strength, stiffness and toughness but costs more • Tungsten carbides can be used for smaller diameter rolls • Rolls are polished for cold-working and special applications • Rolls are heat specific-misuse results in heat checking and spalling Lubricants • Hot Rolling Ferrous alloysNone or Graphite • Hot Rolling Non-Ferrous Alloys-Oils, emulsions and fatty acids • Cold Rolling-Oils, emulsions, paraffin and fatty oils 13.5 Various Rolling Processes and Mills • • • • • • • Shape Rolling Roll Forging Skew Rolling Ring Rolling Thread rolling Rotary Tube Piercing Tube Rolling Shape Rolling • Used for straight and long structural shapes • I-beams, rails, channels • Structures usually formed at higher temperatures • Requires a series of rolls (material deformed nonuniformly) Shape Rolling Roll Forging • Aka cross rolling • Cross section of a round bar is shaped by passing it through rolls with varied groves • Used to produce leaf springs, knives and hand tools Skew Rolling • Similar to roll forging • Used for making ball bearings • Wire/rod is fed into the roll gap to form spherical blanks Ring Rolling • • • • • • Used to create large rings for rockets and turbines, jet engine cases, flanges and reinforcing rings for pipes Involves using two rollers to expand a thick small ring into a thin large ring Utilizes a series of rollers, driven and stationary The rings thickness is reduce while its diameter is increased (volume of material stays the same. Pieces can be as big as 3m in diameter Advantages: short production time, close tolerances, material savings, increased strength (favorable grain flow) Thread Rolling • Thread s are formed on round rods or wire by passing between dies • Cold forming process • Two reciprocating dies or rotary dies • Used to create threads on screws, bolts etc. • Production rates of up to 80 pieces per second • Generates treads with good strength (cold working) • Compressive residual stresses improve fatigue life • Gears can also be produce in a similar manner • Lubrication is especially important in thread rolling for finish surface and integrity Rotary Tube Piercing • Aka Mannesmann Process • Used to make long, thick-walled seamless pipe and tubing • Hot working process • Developed in the 1880’s • Rolled bar under cyclical compression develops a cavity that grows down the tube • Cavity is then expanded/pierced by a floating mandrel Tube Rolling • Process used to reduce the diameter and thickness of pipes/tubes • With or without mandrels • Process can be stepped 13.5.1 Integration Mills Large facilities that integrate the entire production of a part Includes: production of metals, casting rolling and the finished product MiniMills Recycles scrap metals, usually from local sources to reduce cost, and casts and rolls the metals Usually only produce one kind of product (rod, bar, angle iron) Forging of metals – Forging is the basic process which the material is shaped by compressive forces that is applied through various tools and dies. – Forging operations create discrete parts – Forged parts have good strength and toughness because the grain of the metal can be controlled, thus making ideal for highly stressed applications, such as large rotors for turbines, gears, bolts and rivets, railroads, aircraft, and a variety of other transportation equipment. Open-Die forging – Simplest type of forging – Dies are inexpensive – Wide range of part sizes, ranging from 301000lbs – Good strength qualities – Generally good for small quantities – Limited to simple shapes – Difficult to hold close tolerances – Needs to be machined to final shape – Low production rate – Poor utilization of materials – Highly skilled operation 1100 Ton Hydraulic Forging Press and 20 Ton Capacity Manipulator Open-Die forging Impression Die Forging – Better properties of Open Die Forgings – Dies can be made of several pieces and inserts to create more advanced parts – Presses can go up to 50,000 ton capacities – Good dimensional accuracy – High production rates – Good reproducibility – High die cost – Machining is often necessary – Economical for large quantities, but not for small quantities Completed part before removal of the flash Impression Die Forging operation – This form of forging is used to make more complicated parts from Blank bar stock. The Blanks are compressed between two or more dies to shape the part. Once the part is shaped, the flash is removed by either grinding it, trimming, or machining. Precision Forging – – – – – – – Close dimensional tolerances Very thin webs and flanges are possible Very little or no machining is required Little or no scrap after part is produced Cheaper to produce from less finishing operations and faster production Typical applications are gears, connecting rods, and turbine blades Common materials used in precision forging are aluminum, magnesium alloys, steel, and titanium Some examples of precision forged products: Piston heads, connecting rods, and turbocharger fans – – – – – High forging forces Thus higher capacity equipment is required Intricate dies leading to increased die cost Precise control over the Blank’s volume and shape Accurate positioning of the Blank in the die cavity Forging Operations • • • • • Coining Heading Piercing Isothermal forging Rotary and tube swaging Coining • Closed die system • Can produce fine detail • Lubrication cannot be used Heading • Also called upset forging • Care must be taken so that work piece does not buckle • Can be highly automated Piercing • Used to make indentations on the surface of the work piece • Force depends on the cross-sectional area of the punch Isothermal Forging • Also known as hot die forging • Complex parts with good dimensional accuracy can be made • It is expensive and has low production rates • Can be economical for intricate forge designs. • Aluminum, titanium, and other super alloys are typically used Rotary Swaging • Rotary swaging – Work piece remains stationary while the dies rotate – Dies strike the piece up to 20 times a second – Dimensional tolerances are around .05 to .5m – Suitable for medium to high production rates Tube swaging • Used to decrease the diameter of a tube with or without a mandrel Forgeability of Metals - Upsetting test • Uses 2 flat dies Hot twist test – The specimen is twisted until failure – Done at different temperatures – The temperature related to the maximum twists becomes the forging temperature. Forging Defects • Insufficient material causes laps (voids in the work piece) • Excessive material causes internal cracks Grain-flow pattern • If the pattern is perpendicular to the surface, which is called end grains, the environment can attack the surface making it rough. Die Design, Materials, and Lubrication • Die design relies on the properties of the work piece, distortion, most importantly the knowledge of the material flowing to the least resistance. • Software has helped model the forging process • Design features – The parting line is at the largest cross-sectional area – Designed in such a way that the dies lock together – Flash is limited to 3% of the greatest thickness of the part – Draft angles are necessary in almost all forging • Internal angles range from 7 to 10 degrees • External angles range from 3 to 5 degrees – Careful selection of radii for corners and fillets • Small radii tend to wear the die and shorten it’s life Die Materials and Lubrication • General requirements – Strength and toughness at high temperatures – Hardenability – Resistance to thermal and mechanical shock – Wear resistance • Lubrication – Reduce friction and wear – Act as a thermal barrier – Act as a parting agent 14.7, 14.8, 14.9 DIE FAILURES, FORGING MACHINES, AND ECONOMICS OF FORGING. 14.7 DIE MANUFACTURING METHODS- DIE FAILURES • DIES, MANUFACTURING METHODS. • DIE COSTS • DIE FAILURES MANUFACTURING METHODS • CASTING- object formed by a mold • FORGING- forming a hot or cold metal into a fixed shape by hammering, pressing or rolling • MACHINING- To remove excess or unwanted stock by use of machine tools for rough or finish turning, boring, drilling or milling • GRINDING- to reduce the amount of material by pressure or impact • ELECTRICAL AND ELECTRO-CHEMICAL METHODS (EDM)- uses an electrode to create a hole or cut. • LASERS- An intense light beam used to create a cut and shape material DIE COSTS • GREATLY DEPENDS ON THE SIZE • SHAPE AND COMPLEXITY • APPLICATION • SURFACE FINISH • DIE MATERIAL AND MANUFACTURING DIE FAILURES • Improper design • Defective heat-treatment finishing operations • Overheating and heat checking (causes cracking) • Excessive wear • Overloading • Improper alignment • Misuse of die • Improper handling 14.8 FORGING MACHINES • • • • • • • HYDRAULIC PRESSES MECHANICAL PRESSES SCREW PRESSES HAMMERS DROP HAMMERS COUNTERBLOW HAMMERS HIGH-ENERGY-RATE FORGING (HERF) MACHINES Hydraulic and Mechanical press • Hydraulic Press- are slower and involve higher initial costs, and require less maintenance. They consist of a frame with two or four columns, pistons, cylinders, rams, and hydraulic pumps driven by electric motors. • Mechanical Press- are crank or centric type, they are stroke limited the energy is generated by a large flywheel power by an electric motor. Left a mechanical press Right a hydraulic press Principles of Various Forging Machines (cont.) Figure 14.21 (continued) Schematic illustration of the principles of various forging machines. (c) Knuckle-joint press. (d) Screw press. (e) Gravity drop hammer. Screw Presses • Screw presses- derive their energy from a flywheel and are energy limited. The forging load is transmitted by a large vertical screw, and ram comes to a stop when energy is used up. They are used for open-die and closed-die forging operations. Used for small production quantities and for thin parts. Hammers, drop hammers and counterblow hammers. • Hammers- derive their energy from the potential energy, which is then converted into kinetic energy, which makes them energy limited. To complete forging several successive blows are usually made onto the same die. They are the most versatile and least expensive type of forging equipment. • Drop hammers- the ram is accelerated by a steam air or hydraulic pressure usually 750kPa. • Couterblow hammers- This type has two rams that simultaneously approach each other horizontally or vertically to forge a part. They operate in high speeds and transmit less vibrations to their base. High-energy-rate forging (HERF) machines. • HERF machines- in this type of machine the ram is accelerated rapidly, by high pressures and gases, and parts are forged usually with one blow at very high speeds. • Problems with HERFS machines- there are problem with maintaining such machines and operating them are also a hassle. Safety and die breakage are considerations that cause problems with HERFS and make them undesirable to the industry. 14.9 Economics of Forging • • • • Complexity of the forging Tool and die costs Die material Size of forgings Works Cited • http://www.me.gatech.edu/jonathan.colton/me4210/deform.h tml • http://images.google.com/imgres?imgurl=http://wwwmaterials.eng.cam.ac.uk/mpsite/process_encyc/pictures_for_d etails/forging4.jpg&imgrefurl=http://wwwmaterials.eng.cam.ac.uk/mpsite/process_encyc/nonIE/forging.html&h=264&w=330&sz=22&tbnid=RzDAS5ziYax5 NM:&tbnh=91&tbnw=114&hl=en&start=13&prev=/images%3 Fq%3Dforging%2Bflash%26svnum%3D10%26hl%3Den%26l r%3D%26safe%3Doff • http://www.qcforge.com/rapidIR/ • http://cmpmedia.globalspec.com/AluminumPrecisionProducts? VID=138521&deframe=1 • http://images.google.com/imgres?imgurl=http://www.fushen g.com/precision/images/casting.jpg&imgrefurl=http://www.fu sheng.com/precision/&h=252&w=320&sz=30&tbnid=rEG6iitN YwFdhM:&tbnh=88&tbnw=113&hl=en&start=69&prev=/imag es%3Fq%3Dprecision%2Bforging%26start%3D60%26dnum %3D20%26svnum%3D10%26hl%3Den%26lr%3D%26safe% 3Doff%26sa%3DN Works Cited • step.polymtl.ca/~coyote/ dragonlance_misc.html FORGING OLD MAN AND MIGET • www.airhydraulics.com/. ../Animation.htm Hydraulic press. • Kalpakjian Schmid Manufacturing Engineering and Technology copy 2001 Prentice-Hall page 347-395 • www.qform3d.com/ en/62.html animation for mechanical press • www.farthingales.on.ca/ bone_tip_machines.html press and dies steel “real” • www.emeraldsurgical.com/ production_tour.htm forging pic with red glow Works Cited • http://www.msm.cam.ac.uk/phasetrans/2002/FR.html