Rolling

advertisement

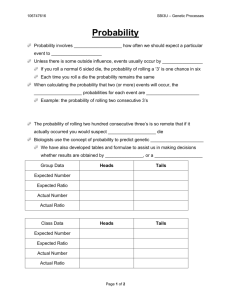

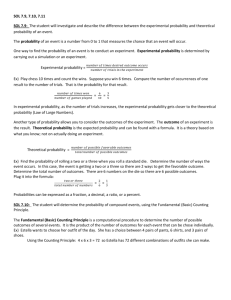

Chapter 13 Rolling of Metals 13.1 Introduction • Rolling: is the process of reducing the thickness or changing the cross section of a long work-piece by compressive forces applied through a set of rolls (F13.1) • Rolling is 1st carried out at elevated temperatures (hot rolling): the coarse-grained, brittle, and porous structure of the ingot or the cont. cast metal is broken down into a wrought structure having finer grain size and enhanced properties. • Subsequently, rolling is carried out at room temperature (cold rolling), whereby the rolled product has higher strength and hardness and a better surface finish. But more energy required? • Plates: thickness more than 6mm and up to 300mm like bridges • Sheets: thickness less than 6mm and can reach 0.28mm as in Aluminum beverage cans. Flat-Rolling and Shape-Rolling Processes Figure 13.1 Schematic outline of various flatrolling and shape-rolling processes. Source: After the American Iron and Steel Institute. Flat-Rolling Process • A schematic illustration of the flat rolling process is shown in F13.2a. • A strip of thickness ho enters the roll gap and is reduced to thickness hf by a pair of rotating rolls. • The surface speed of the rolls is Vr • The velocity of the strip increases from its entry value Vo as it enters the roll gap and it id maximum at the end Vf Flat rolling • Because surface speed of the roll is constant, there is relative sliding between the roll and the strip along the arc of contact in the roll gap, L • At the neutral point or no-slip point, the velocity of the strip equals that of the roll. • To the left of this point, the roll moves faster than the strip, to the right, the strip moves faster than the roll. • Therefore, the frictional forces, act on the strip as shown in F13.2b Flat rolling – Frictional Forces • The rolls pull the material into the roll gap through a net frictional force on the material which must be to the right. • The max possible draft: difference between the initial and final thickness, (ho – hf), is a function of the coefficient of friction, m, and the roll radius, R: ho – hf = m2R • The higher the friction and the larger the roll radius, the greater the max draft. Flat rolling – Roll Force and Power Requirement • The roll force, F = LwYav • Yav = average true stress of the strip in the roll gap. L R (ho hf ) • This equation is used for a frictionless situation. • The higher the coefficient of friction is between the rolls and the strip, the greater the divergence, and the formula predicts lower roll force than the actual force. • The power required per roll can be estimated by assuming that the force F acts in the middle of the arc of contact: a = L/2 2 FLN power kW 60000 EXAMPLE |3.l Calculation of Roll Force and Torque in Flat-rolling • An annealed copper strip 250 mm wide and 25 mm thick is rolled to a thickness of 20 mm in one pass. The roll radius is 300 mm, and the rolls rotate at 100 rpm. Calculate the roll force and the power required in this operation. Solution: • The average true stress, Yavg, for annealed copper is determined as follows: First note that the absolute value of the true strain that the strip undergoes in this operation is EXAMPLE |3.l Calculation of Roll Force and Torque in Flat-rolling • Referring to figure 2.6 the annealed copper has true unstrained stress 80 MPa and at 0.223 true strain, the true stress is 280 MPa, then the average true stress is 180 MPa. Flat rolling – Reducing Roll Force • • • • Roll force can cause flattening of the rolls. Also, the roll stand (F13.3) may stretch under the roll force to such an extent that the roll gap can open up significantly. Therefore, the rolls have to be set closer than was calculated, to compensate for this deflection and to obtain the desired final thickness. Roll forces can be reduced by any of the following means: 1. Reducing friction. 2. Using smaller diameter roll, to reduce contact area 3. Smaller reductions per pass 4. Rolling at elevated temperatures 5. Apply longitudinal tension to the strip during rolling, thus reducing the compressive stresses required to deform the material plastically. Roll Arrangements Figure 13.3 Schematic illustration of various roll arrangements: (a) four-high rolling mill showing various features. The stiffness of the housing, the rolls, and the roll bearings are all important in controlling and maintaining the thickness of the rolled strip; (b) two-high mill; (c) three-high mill; and (d) cluster (or Sendzimir) mill. Flat rolling – Reducing Roll Force • Back tension is applied to the sheet by applying a braking action to the supply reel. • Front tension is applied by increasing the rotational speed of the take up reel. • Rolling can also be carried out by front tension only, with no power supplied to the rolls (Steckel rolling) Flat rolling – Geometric Considerations (roll bending) • Roll forces tend to bend the rolls elastically (F13.4a). • Therefore, the rolled strip tends to be thicker at its center than at its edges. • To avoid this problem, grind the rolls so that the their diameter at the center is slightly larger than at their edges. • For rolling sheet metals, the radius of max camber is generally 0.25mm greater than that at the edges of the roll. • a particular camber is correct only for a certain load and a certain strip width. • To reduce the effects of deflection, the rolls can be subjected to bending moments at their bearings, to simulate camber. Flat rolling – Geometric Considerations (thermal camber) • Because of heat generated by plastic deformation, rolls can become slightly barrel-shaped (thermal camber) • To avoid the strip being thinner in the center, there should be some way to compensate this camber. • Therefore, the net camber can be controlled by varying the location of the coolant on the HR • Roll forces also tend to flatten the rolls elastically. • This flattening produces large roll radius, hence, larger contact area for the same draft. • Therefore, the roll force increases. Flat rolling – Geometric Considerations (spreading) • In rolling plates and sheets having high width-to-thickness ratios, width of the material remains constant. • With smaller ratios (square x-section), the width increases in the roll gap (spreading), F13.5 • Spreading can be prevented by use of vertical rolls in contact with edges of the rolled product. Figure 13.5 Increase in strip width (spreading) in flat rolling. Note that similar spreading can be observed when dough is rolled with a rolling pin. Flat rolling practice - Effects of Hot Rolling • A cast structure is typically dendritic, and it includes coarse and non-uniform grains, is usually brittle and may contain porosities. • HR converts the cast structure to a wrought structure (F13.6), which has finer grains and enhanced ductility. • Temperature ranges for HR from 450oC for Al alloys to 1250oC for alloy steels, and up to 1650oC for refractory alloys. Flat rolling practice • The product of 1st HR operation is called a bloom or slab. • Bloom: square x-section, at least 150mm side, Slab: rectangular x-section. • Billets: square x-section smaller than blooms. • In HR blooms, slabs, and billets, the surface is usually conditioned prior to rolling by any of the following means: 1. Use of a torch to remove heavy scale or by rough grinding 2. In CR scale is removed by etching with acids. Flat rolling practice • Pack rolling: two or more layers of metal are rolled together to improve productivity (Al foil) • To improve flatness, the rolled strip is passed through a series of leveling rolls (F13.7) Figure 13.7 (a) A method of roller leveling to flatten rolled sheets. (b) Roller leveling to straighten drawn bars. Flat rolling practice - Defects • Scale, rust, scratches, and cracks may be caused by inclusions and impurities in the original cast material, or due to surface and material conditions • Wavy edges are the results of roll bending: the strip is thinner along its edges than at its centers (F13.3a). Because the edges elongate more than the center, they buckle because they are restrained from expanding freely in the long. direction. • cracks shown in F13.8b and c are due to poor material ductility at the rolling temp. • Alligatoring (F13.8d): caused by nonuniform deformation or by the presence of defects in the original cast billet. • Edge defects are removed by shearing and slitting operations. Figure 13.8 Schematic illustration of typical defects in flat rolling: (a) wavy edges; (b) zipper cracks in the center of the strip; (c) edge cracks; and (d) alligatoring. Flat rolling practice – residual stresses • Because of non-uniform deformation of the material in the roll gap, residual stresses may develop. • Small diameter rolls or small reductions per pass tend to deform the metal plastically at its surfaces (F13.9a) • Large diam rolls & high reductions tend to deform the bulk more than the surfaces (F13.9b). This is due to the frictional constraint at the surfaces along the arc of contact Figure 13.9 (a) Residual stresses developed in rolling with small-diameter rolls or at small reductions in thickness per pass. (b) Residual stresses developed in rolling with large-diameter rolls or at high reductions per pass. Note the reversal of the residual stress patterns. Rolling Mills • Width of rolled products: up to 5m and be as thin as 0.0025mm. • Rolling speeds: up to 25m/s for CR. • 2-high or 3-high mills are used for HR in initial breakdown passes on cast ingots or in continuous casting, with roll diam range from 0.6m to 1.4m. • 4-high mills and cluster mills are based on the principle that small diameter rolls lower roll forces & power req. and reduce spreading. • Also, when worn or broken, small rolls can be replaced at less cost than large rolls. Figure 13.10 A general view of a rolling mill. Source: Courtesy of Ispat Inland. Rolling Mills • Tandem rolling (F13.12): the strip is rolled continuously, through a number of stands to smaller gages with each pass. • Rolls have to have strength and resistance to wear. • Common roll materials: cast iron, forged steel, Tungsten Carbide. • HR of ferrous alloys usually done without lubricants, (may use graphite) • Water based solutions are used to cool the rolls and to break up scale. • Non-ferrous alloys are HR with a variety of compounded oils, emulsions, and fatty acids. • CR is done with water soluble oils or low viscosity lubricants such as mineral oils, emulsions, paraffin and fatty oils. Shape Rolling Operations –Ring Rolling • Shape rolling (F13.13) • A thick ring is expanded into a larger diam ring with a reduced x-section. • The ring is placed between two rolls, one of which is driven (F13.14a), and its thickness is reduced by bringing the rolls closer together as they rotate. • The process can be done at room temp or at high temp, depending on size, strength, and ductility of the work piece material. • Advantages: short production times, material saving, close dimensional tolerances, favorable grain flow in the product. Shape Rolling of an H-section part Figure 13.12 Steps in the shape rolling of an Hsection part. Various other structural sections, such as channels and I-beams, also are rolled by this kind of process. Ring-Rolling Figure 13.15 (a) Schematic illustration of a ring-rolling operation. Thickness reduction results in an increase in the part diameter. (b-d) Examples of cross-sections that can be formed by ring-rolling. Roll-Forging Figure 13.13 Two examples of the roll-forging operation, also known as cross-rolling. Tapered leaf springs and knives can be made by this process. Source: After J. Holub. Production of Steel Balls Figure 13.14 (a) Production of steel balls by the skew-rolling process. (b) Production of steel balls by upsetting a cylindrical blank. Note the formation of flash. The balls made by these processes subsequently are ground and polished for use in ball bearings. Shape Rolling Operations – Thread Rolling • Threads are formed on rod or wire with each stroke of a pair of flat reciprocating dies (F13.15a) • Another method uses rotary dies (F13.15b) at prod rates as high as 80 pieces per sec. Figure 13.16 Thread-rolling processes: (a) and (c) reciprocating flat dies; (b) two-roller dies. (d) Threaded fasteners, such as bolts, are made economically by these processes at high rates of production. Source: Courtesy of Central Rolled Thread Die Co. Shape Rolling Operations – Thread Rolling • Advantages: no scrap, good strength, very smooth surface finish, induced compression residual stresses, improving fatigue life. • Machining threads cuts through the grain flow lines of material, while rolling leaves a grain-flow pattern that improves the strength of the thread (F13.16) Machined and Rolled Threads Figure 13.17 (a) Features of a machined or rolled thread. Grain flow in (b) machined and (c) rolled threads. Unlike machining, which cuts through the grains of the metal, the rolling of threads imparts improved strength because of cold working and favorable grain flow. Production of Seamless Pipe and Tubing • Rotary tube piercing is a HW process for making long, thick-walled seamless pipe and tubing (F13.17). • based on the principle that when a round bar is subjected to radial compressive forces, tensile stresses develop at the center of the bar. • When it’s subsequently subjected to cyclic compressive stresses (F13.17b), a cavity begins to form at the center of the bar. Cavity Formation in Bar Figure 13.18 Cavity formation in a solid, round bar and its utilization in the rotary tubepiercing process for making seamless pipe and tubing. (see also Fig. 2.9.) Production of Seamless Pipe and Tubing • Rotary tube piercing is carried out using an arrangement of rotating rolls (F13.17c). • Axis of rolls are skewed, in order to pull the round bar through the rolls by axial comp of the rotary motion. • An internal mandrel assists the operation by expanding the hole and sizing the inside diameter of the tube. • The diameter & thickness of tubes and pipes can be reduced by tube rolling (F13.18) Continuous casting and rolling: integrated mills and minimills • Integrated mills: large facilities that involve complete activities from the production of hot metal in a blast furnace to the casting and the rolling of finished products. • Minimills: scrap metal is melted in electric furnaces, cast continuously, and rolled directly into specific lines of products. • Each minimill produces one kind of rolled product. • The scrap metal is obtained locally to reduce transportation costs (old machinery, cars, and farm equipment) • Minimills have the economic advantages of low investment. Forming of Solid Rocket Casings Figure 13.20 The Space Shuttle U.S.S. Atlantis is launched by two strapped-on solidrocket boosters. Source: Courtesy of NASA. Figure 13.21 The forming processes involved in the manufacture of solid rocket casings for the Space Shuttles.