Ch3 Product and Process Design

advertisement

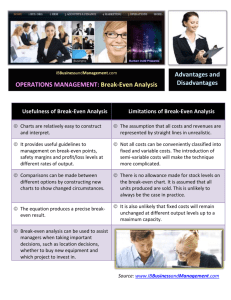

Chapter 3 Product & Process Design Part 1: Product Design Product/Service Design Process A process that defines the Appearance and features, Quality characteristics, Spec limits and target levels Inputs (labor, capital, materials) Transformation process Supply chain – suppliers, channels of distribution of a product/service that a company is planning to produce. Steps in Product Design Process Idea Development Product Screening Preliminary Design and Testing Final Design Idea Development Someone thinks of a unsatisfied need Then someone thinks of a product/service to satisfy it e.g. customers, marketing, engineering, reverse engineering Idea Development 2006 Industrial Design Excellent Awards (IDEAs) Winners - (BW, 7/10/06, p. 77) “Bumpbrella” Concept Umbrella Company: RKS Design An inflatable umbrella that uses a bicycle pump in the center for the arm. A totally new design looking for a company to make it. Idea Development 2-Second Tent Designer: Decathlon, France Spring hoops allow you to throw this 2person tent into the air, and it opens before hitting the ground. Two second to open, 15 seconds to close. Idea Development Idea Development “How Failure Breeds Success” (BW, 7/10/06, p. 48) “Everyone fears failure. But breakthroughs depend on it.” “Innovation requires risk-taking.” “Many companies have found success in the ashes of the memorable misses.” Idea Development McDonald’s Hula Burger (1962) Cheese-topped grilled pineapple on a bun for Chicagoans who avoided eating meat on Fridays. Big flop! McDonald’s decided to try something less extreme: Came up with tastier hamburger-fee alternative: the Filet-O-Fish, now a McDonald’s classic. Idea Development Ford’s biggest mistake – 1958 Edsel—lead to its greatest success. Edsel was called the “Titanic of the auto industry.” Came in two sizes – big and bigger Overhyped, oversized, overpriced. Idea Development Idea Development Designed based on a “hunch” about what consumers want. Abandoned in 1960, just after 2,800 cars produced. Ford substituted “research” for “hunches.” Found out that consumers wanted style and affordability Result? 1964 Mustang Idea Development How do companies get employees to come up with creative and innovative ideas? By shifting from risk-adverse culture to a risk-taking culture. In risk-taking culture, employees are encouraged to Explore, Experiment, Foul-up, sometimes Then repeat. Idea Development Shift not easy Fear of blame for mistakes makes employees want to play it safe and not take risks. Companies must design performancemanagement systems that reward risktaking. Coca-Cola, Intuit, GE Idea Development Coke’s Head of Marketing, Strategy, and Innovation, Mary Minnick idea development strategy Stop thinking in terms of existing drink categories Start thinking broadly abut why people consume beverages in the first place. Then come up with products that satisfy those needs before the competition. Step 2 - Product Screening Screen ideas Some screening criteria are fit with existing facilities and labor skills, size of potential market, expected market share, share of potential market expected profit, break-even point Step 3 – Preliminary Design and Testing Suppliers involved, Transformation process is designed, Prototype built, Tricycle developed system for digitally modeling carpets and textiles so manufactures can make prototypes of new designs without making samples for architects and interior designers. Cuts development costs. (BW, 7/10/06, p.81) Prototype tested for Functionality Acceptance by potential customers Design and Testing Corning Developed new chip in 1998 that would help in DNA research Killed in 2001 Customers had not been brought in early enough to help assess its marketability. Market potential was too small to breakeven in a reasonable amount of time. Step 4 – Final Design Prototype design is modified based on test results Final design approved Production begins Product Design Process vs. Deming’s PDCA Cycle? PDCA P = plan D = do C = check (or study) A = act Product Design Idea development Product screening Preliminary design and testing Final design How is Product Design Process Related to Deming’s PDCA Cycle? Plan Do Idea Development Product screening Preliminary Design and Testing Check, Act Final Design Good Product Design Process Should: Design products/services that match the needs and preferences of the targeted customer group Design products that are as easy as possible to make (product manufacturability). Use concurrent engineering Product Manufacturability Achieve it by Simplification Standardization Minimize number of parts Design parts for multiply products Modular (prefabricated) design Product Manufacturability Matsushita, Electronic Giant in Japan One division has 7 factories that make 35 million phone, fax machines, printers and other products annually. 1,500 shape and color variations in phones alone Engineers had to rearrange as many as 77 circuit-board parts for each new model. Product Manufacturability Setting up production for every type of board was too time consuming. Company designed a new circuit board that would need only slight changes for each model. Reduced cycle time and lowered defect rate to under 1%. Product Manufacturability Bo Andersson, GM’s head of purchasing, wants GM cars to share more parts, the way Japanese automakers do. Shared parts results in fewer parts Fewer parts saves millions. Also want to ax many of GM’s 3,200 suppliers by weeding out weak suppliers. Product Manufacturability Andersson is asking: Why do we have two dozen different seat frames when Toyota has only two? Answer? Why do we have 12 V6 engines when Toyota has just a few? Progress has been made: GM once had 20 fuel pumps, now it has 5. Wants to use savings to make better interiors. Product Manufacturability Goal is twofold: to make one part for many models To reduce number of components in each part. Product Manufacturability GM discovered that door hinges on big SUVs and trucks could be made out of 3 components instead of 5. This would save $21 a truck, or about $100 million over several years. Designing a new hinge requires months of testing, which is costly. Must weight costs and benefits. “Over-the–wall” vs. Concurrent Engineering Design Process Old “over-the-wall” sequential design process should not be used Each function did its work and passed it to the next function Replace with a Concurrent Engineering, where cross functional design teams work together to involve customers early, develop specifications, solve potential problems, reduce costs, & shorten time to market Concurrent Engineering Concurrent Engineering GMs North American operations had completely separate engineering groups for cars and trucks. Within each group, there were separate teams for almost every type of vehicle. Each team worked independently Concurrent Engineering Engineers and designers had no idea how much money was being wasted making different version of the same things. Andersson is pushing a company wide effort to break down silos and get divisions talking to one another about how to share parts and save money. Global Trends in Design China, Twain, Korea, Hong Kong companies are committing huge resources to product design in order to build global brands. (BW, 7/10/06, p. 77) They’re competing less and less on price and more on differentiation and value to consumer. Coke’s Design Process Anticipate the customer Coke’s marketers are encouraged to think more creatively about consumer’s needs Retool tired brands Cost of launching new brands is expensive Reposition existing brands Coke used its Tab brand to create a new energy drink for women Using Sprite name for a new energy drink in France. Coke’s Design Process Engage partners Coke brings bottlers into the decisionmaking process to get their input and brings them on board from the outset. Don’t fear failure Product Screening Tool – Break-Even Analysis Is expected sales large enough to exceed the break-even point? Break-even point (BE) is the number of units of a product/service that a company must sell to cover its total cost. Break-even point is where total revenue equals total cost, or profit equals zero. Break-Even Analysis Total Revenue = Total cost or Profit = Total Revenue – Total Cost = 0 Notation Q = expected sales in number of units sold SP = selling price per unit F = Total fixed costs VC = Variable cost per unit Notation Total Revenue = (SP)*Q Total Cost = Total Fixed Cost + Total Variable Cost Total fixed costs = F Total Variable Cost = (VC)*Q Total Cost = F + (VC)*Q Finding the Break-Even Point Total Revenue = Total cost (SP)*Q = F + (VC)*Q (SP)*Q - (VC)*Q = F Q(SP - VC) = F Q = QBE = F/(SP - VC) Break-Even Decision Rule If Q > QBE, Total Rev. > Total Cost and Profit > 0 If Q < QBE, Total Rev. < Total Cost and Profit < 0 Break-Even Analysis Example 1 A company is planning to introduce a new product. The expect to sell 875 units of the new product. The sales price is set at $25 per unit. The fixed cost of producing the product is $10,000. The variable cost per units is $15. Should the company develop the new product? Solution to Example 1 Q = expected sales SP = selling price per unit =$25 F = Total fixed costs = $10,000 VC = Variable cost per unit = $15 Solution to Example 1 QBE F SP VC $10,000 $25 $15 1,000 units Solution to Example 1 If the company sells 1,000 units of the new product, it will breakeven. If the company expects to sell more than 1,000, it will make a profit. If the company sells less than 1,000 units, it will incur a loss. Since the company expects to sell 875 units, which is less than the BE quantity, the company should not develop the new product. Example 2 A company is planning to establish a chain of movie theaters. It estimates that each new theater will cost approximately $1 Million. The theaters will hold 500 people and will have 4 showings each day with average ticket prices at $8. They estimate that concession sales will average $2 per patron. The variable costs in labor and material are estimated to be $6 per patron. They will be open 300 days each year. Example 2 1. What must average occupancy be to break-even? 2. What is the annual capacity utilization rate? 3. What is the chains profit if they sell 300,000 ticket next year? Solution 1. What must average occupancy be to break-even? Q = ticket sales per year Total cost = $1,000,000 Ticket SP = $8 Concession sales/patron= $2 Sales revenue/patron = $8 + $2 = $10 VC = $6 Solution 1. What must average occupancy be to break-even? QBE F SP VC $1,000,000 $10 $6 250,000 ticket per year Solution 2. What is the capacity utilization rate? Annual Capacity (AC) = 4 shows per day x 300 days per year x 500 people = 600,000 patrons Capacity utilization rate (CUR) = (QBE/AC) x 100% CUR = (250,000/600,000) x 100% = 41.7% Solution 3. What is the chains profit if they sell 300,000 ticket next year? Total Revenue = 10Q Total Cost = 1,000,000 + 6Q Profit = Total Revenue – Total Costs Profit = $10Q – (1,000,000 + $6Q) = -1,000,000 + 4Q Solution 3. What is the chains profit if they sell 300,000 ticket next year? Q = 300,000 P = -1,000,000 + 4(300,000) = $200,000 Product life cycle Due to changing product demand over time Stages of product life cycle stages Introduction Growth Maturity Decline Is it long enough to justify launching new product? Product life cycle Product life cycle Where is break-even point on product life cycle? The earlier it is on the product life cycle, the ???