EBB 427

advertisement

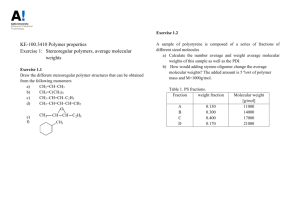

UNIVERSITI SAINS MALAYSIA EBB 427 Commodity and Engineering Plastics UNIVERSITI SAINS MALAYSIA Types of Thermoplastics • Various possible classification scheme for polymers; – Crystalline vs non crystalline – Properties or end-use – Form (fibers, coatings, foam, etc.) – Polymerization process – response of the polymer to heat and solvent Commodity Plastics • Examples; – Polyethylene (PE)- plastic bag, hot-melt glue gun – Polyvinylchloride (PVC)- pipe – Polystyrene (PS)-toys, disposable drinking glass Engineering Plastics • Examples; – Polyamide (PA)- unlubricated gear, sji boots – Polycarbonate (PC)- compact disc, motorcycle helmet – Ultrahigh molecular weight PE – pen tips Thermoplastic Materials (Commodity Plastics) • All of the commodity plastic which will be considered here are made by addition polymerization method • The differences between the monomers used to make these commodity t’plastics are the functional groups attached to the carbon In all cases, three hydrogens are attached to the carbon-carbon double bond Steric Hindrance • Steric effects arise from the fact that each atom within a molecule occupies a certain amount of space. • The substitution of one functional group on the carboncarbon double bond, relates to steric hindrance(interference because of size) • When the functional groups are small (such as hydrogen), little steric hindrance • Steric hindrance increases, as larger functional group are substituted onto the C-C double bond- results of restricted polymer motion, less ability to pack densely, and change in physical, mechanical and chemical properties • PP and PE are often given a special name, polyolefins • Polyolefins means ‘oil like’ & refer to oily and waxy feel these materials have • Consists of only carbon and hydrogen, they are all aliphatic groups Polyethylene (PE) • PE is the simplest of all polymers, with 2 C and 4 H in the basic polymer repeating unit • High molecular weight, relatively insensitive to most solvent (used for chemical reaction vessels or pipe) • However joining is a problem because of solvent resistance of PE (overcome by using bonding technique that melt the surface of the PE parts) • The thermal conductivity is good, however Tm of PE is low - limited applications at high temp. Polyethylene (PE) • Low cost and ease of manufacture • Applications; packaging, container, toys and houseware • The major differences of PE molecules occur during polymerization process- formation of branching • Branching- formation of side chain off the basic polymer backbone • Number of side chain and length of side chaineffect the properties Classification of polyethylenes • Polyethylene is classified into several different categories based mostly on its density and branching. The mechanical properties of PE depend significantly on variables such as the extent and type of branching, the crystal structure, and the molecular weight. • UHMWPE (ultra high molecular weight PE) • HMWPE (high molecular weight polyethelyene) • HDPE (high density PE) • HDXLPE (high density cross-linked PE) • PEX (cross-linked PE) • MDPE (medium density PE) • LDPE (low density PE) • LLDPE (linear low density PE) • VLDPE (very low density PE) Classification of polyethylenes • UHMWPE is polyethylene with a molecular weight numbering in the millions, usually between 3.1 and 5.67 million. The high molecular weight results in less efficient packing of the chains into the crystal structure as evidenced by densities less than high density polyethylene (e.g. 0.935 - 0.930). The high molecular weight results in a very tough material. • HDPE is defined by a density of greater or equal to 0.941 g/cc. HDPE has a low degree of branching and thus stronger intermolecular forces and tensile strength. • PEX is a medium- to high-density polyethylene containing cross-link bonds introduced into the polymer structure, changing the thermoplast into an elastomer. Classification of polyethylenes • MDPE is defined by a density range of 0.926 0.940 g/cc. • LLDPE is defined by a density range of 0.915 0.925 g/cc. is a substantially linear polymer, with significant numbers of short branches • LDPE is defined by a density range of 0.910 0.940 g/cc. LDPE has a high degree of short and long chain branching, which means that the chains do not pack into the crystal structure as well. • VLDPE is defined by a density range of 0.880 0.915 g/cc. is a substantially linear polymer, with high levels of short chain branches Branching Mechanism for PE Effect of Branching on Several Polymer Properties LDPE, HDPE, LLDPE What is the relationship between brance of PE with the density??? Relate the properties of LDPE, HDPE & LLDPE with the structure!!! Relationship Between Density and Molecular Weight in PE • Overall trend, increases in molecular weight, result in increase in crystallinity and density Molecular weight distribution (MWD) -Narrow MWD – results in sharp melting point -Broad MWD – melting occur at a wide range of temp. (low molecular weight melt first, act as a lubricant for Higher molecular weight) PE • Crosslinked PE- can be done by electron irradiation or by chemical methods • Electron irradiation is more effective in amorphous region than crystalline region • Crosslinking changes thermoplastic to thermoset materials PE • Depending on the crystallinity and molecular weight, a melting point and glass transition may or may not be observable. The temperature at which these occur varies strongly with the type of polyethylene. • For common commercial grades of medium-density and highdensity polyethylene, the melting point is typically in the range 120130 degrees C. The melt point for average commercial low-density polyethylene is typically 105-115 degrees C. Most LDPE, MDPE, and HDPE grades have excellent chemical resistance and do not dissolve at room temperature because of the crystallinity. • Polyethylene (other than cross-linked polyethylene) usually can be dissolved at elevated temperatures in aromatic hydrocarbons (i.e. toluene, xylene) or chlorinated solvents (i.e. trichloroethane, trichlorobenzene). Polypropylene (PP) • Polypropylene or polypropene (PP) is a thermoplastic polymer, used in a wide variety of applications, including food packaging, textiles, laboratory equipment, loudspeakers, automotive components, and polymer banknotes. An addition polymer made from the monomer propylene, it is unusually resistant to many chemical solvents, bases and acids. Its resin identification code is • level of crystallinity intermediate between that of low density polyethylene (LDPE) and high density polyethylene (HDPE) • Although it is less tough than LDPE, it is much less brittle than HDPE • This allows polypropylene to be used as a replacement for engineering plastics, such as ABS • Polypropylene has a melting point of 160ºC. Food containers made from it will not melt in the dishwasher, and do not melt during industrial hot filling processes Polypropylene (PP) • Presence of pendent CH3 groupformation of 3 different types of PP Different Types of PP • Isotactic polymers refer to those polymers formed by branched monomers that have the characteristic of having all the branch groups on the same side of the polymeric chain. The monomers are all oriented in the same way: If we represent a monomer by AB then an isotactic polymer is AB-AB-AB-AB-AB-etc. • Besides Isotactism, there are other two types of stereoregularity or tacticity frequently found in the scientific literature: • Syndiotactism- The monomers have alternating orientations within the polymer chain: AB-BA-AB-BA-AB-BA-etc. • and Atactism- The monomers have random orientations within the chain: e.g. AB-AB-BA-AB-BA-BA-BA-AB-etc. Polyvinyl chloride (PVC) • Globally, over 50% of PVC manufactured is used in construction. As a building material, PVC is cheap and easy to assemble. • In recent years, PVC has been replacing traditional building materials such as wood, concrete and clay in many areas. • The symbol for polyvinyl chloride developed by the Society of the Plastics Industry so that items can be labelled for easy recycling is: PVC PVC pipes Adhesive film Adhesive for arts & craft Rigid PVC • Compared to PE and PP, unmodiffied PVC is more rigid and stronger • Rigid PVC is used in many applications, fillers are often used to reduce the cost of the product, stiffness, thermal stability, however reduce toughness Size representations of common pendent groups in commodity polymers - The Cl atom is approximately the same size as the CH3 group - The size of Cl atom is sufficient to interfere the close packaging and Crystallization of PVC- resulting largely amorphous polymer (10% crystallinity) Plasticized PVC • Plastisizers are added to PVC, the plastic become flexible than the rigid PVC • Plasticizers work by embedding themselves between the chains of polymers • Space them apart (increasing of the "free volume"), and thus significantly lowering the glass transition temperature for the plastic and making it softer Polystyrene (PS) • Carbon-carbon double bond to which a benzene ring and three hydrogens are attached • The size of benzene group reduce the ability of the polymer chain to bendprevent crystallization-100% crystallinity Polystyrene (PS) • Polystyrene's most common use, however, is as expanded polystyrene (EPS). Expanded polystyrene is produced from a mixture of about 5-10% gaseous blowing agent and 90-95% polystyrene by weight • Expandable polystyrene is the lightweight material of which coffee cups and takeaway food containers are made. The voids filled with trapped air give expanded polystyrene low thermal conductivity. This makes it ideal as a construction material and it is used in structural insulated panel building systems. It is also used as insulation in building structures, as molded packing material for cushioning fragile equipment inside boxes, as packing "peanuts", as non-weight-bearing architectural structures (such as pillars), and also in crafts and model building, particularly architectural models. High Impact Polystyrene (HIPS) • Modification of PS can increase selected properties, by creating copolymer and blends • Pure polystyrene is brittle, but hard enough that a fairly highperformance product can be made by giving it some of the properties of a stretchier material, such as polybutadiene rubber. The two materials cannot normally be mixed due to the amplified effect of intermolecular forces on polymer solubility (see plastic recycling), but if polybutadiene is added during polymerization it can become chemically bonded to the polystyrene, forming a graft copolymer which helps to incorporate normal polybutadiene into the final mix, resulting in high-impact polystyrene or HIPS, often called "high-impact plastic" in advertisements. Common applications include use in toys and product casings. HIPS is usually injection molded in production. Acrylonitrile butadiene styrene, (ABS) • Combination materials called ABS has been developed • Styrene and Acrylonitrile monomer can be copolymerized to form random, amorphous copolymer- SAN -ABS is in the middle of triangle. -The properties changes created by increasing the concentration of one materials relative to the other - Noted the presence of HIPS, SAN, ABS Glossary-Important Terms • • • • • Blending Copolymerization Alloying Miscible Compatibility