Yesco_LeanOffice 11-17-09

advertisement

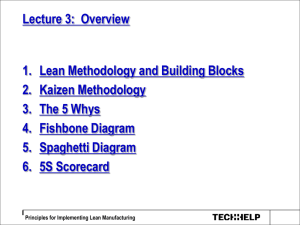

Lean Office Training YOU to Recreate Your World Course Agenda » Lean office overview » Definition of waste » Orientation to YESCO Hawaii » Round one of simulation » Value Stream Mapping (current state) » Implementing lean tools » Round two of simulation » Value Stream Mapping (future state) » Round three final simulation » Final Evaluation 2 Introductions » » » » Who are you? Where are you from? What do you want to learn today? ?’s 3 What is Lean Office? Lean Office is a systematic approach applied to the value chain with an aim to streamline the business processes by: » Eliminating waste » Utilizing lean techniques » Resulting in: Lead time reduction and Productivity improvement 4 Why Lean Office? “In America today we have good people working in poor processes. What we want is good people working in great processes” Michael Hammer 5 Why Lean Office? “ Toyota Production System will not work unless it is used as an overall management system. TPS is not something that can only be used on the Production floor.” Taiichi Ohno 6 Lean Office LEAD TIME REDUCTION 7 Waste Elimination Business as Usual Customer Customer Waste Contact Delivery Lead-Time Lean Systems “Eliminate Non-Value Added Activities” Customer Customer Contact Delivery Lead-Time (Shorter) 8 Value Added vs. Non-Value Added Activities » Value Added (VA) – The customer is willing to pay for it – Physically transforms the product (or document or information) – Is done right the first time » Non-value Added (NVA) – Consumes resources, but does not add value to the product or service » Necessary Non-value Added (N-NVA) – Does not add value to the product or service but are – CURRENTLY NECESSARY – – – – Customer Contract or specification QS 9000 or customer standard Government regulation Current state-of-the-art work method or technology 9 Why Lean Office? » Only 30% of the total costs are directly manufacturing » Where is the rest of the money being spent? 10 Lean Organization Process View Customer Business Operations Delight A streamlined flow of goods or services through an organization in concert with customer demand and requirements We can begin to reduce the complexity of an organization by implementing Lean Tools and Techniques in support processes. We can gain a competitive advantage by streamlining the organization, focusing on these four areas Streamline, Synchronize, and Integrate 1) Identify, manage or break the constraints 2) Eliminate waste and non value added work 3) Synchronize all activities toward customer delight 4) Apply an employee based cross functional continuous improvement plan 11 Business Activities 12 Sites of Waste » Policies – Organizational structure – Management policies and methods » Macroscopic wastes – Supply chain – Office layout » Major wastes – Process and cell level » Microscopic wastes – Operator and computer level 13 Lean = Eliminating the Waste Value Added Defects Overproduction Waiting Non-utilized talent Transportation Inventory Motion Extra processing Typically 95% of Total Lead Time is Non-Value Added!!! ©2006 MMTC 14 Waste of Defects » Money and time wasted to find and fix mistakes » Lack of process controls » Poor work instructions » Inadequate training » Data entry error » Missing information » Missed specifications » Pricing error 15 Waste of Overproduction » » » » » » Making multiple schedules due to system incompatibilities E-mails/memos to everyone Printing extra documents just-in-case More information than the process requires More information than the customer needs Creating reports no one reads 16 Waste of Waiting » » » » » » » » Time lost when people and resources are waiting: Unbalanced workload Equipment break downs Batch processing Waiting for information Waiting for copiers/faxes Waiting for customer response Waiting for an internal response 17 Waiting Waste ©2006 MMTC 18 Waste of Non-Utilized Talent » » » » Unclear job descriptions Lack of training Lack of synergy and collaboration No feedback loop for continuous improvement » Suggestions for improvements that are not investigated/utilized 19 Waste of Non-Utilized Talent 20 Waste of Transportation » Poor office layout » Walking around to correct mistakes and find answers » Retrieving or storing files » Carrying documents to and from shared equipment » Going to get signatures » Taking files to another person 21 Waste of Inventory » » » » » » » Storing of obsolete prints and specs Obsolete databases/files and folders Files pile up between work desks Open projects (WIP) Office supplies E-mails waiting to be read Unused records in a database 22 Inventory Waste 23 Waste of Motion » Looking for items because they are out of place » Mis- or unfiled papers » Saving files everywhere » Handling paperwork that could be electronic » Extra clicks or keystrokes » Working around other open files on desk 24 Waste of Extra Processing » Doing more than is required to meet customer requirements » Unnecessary paperwork » Redundant approvals » Repeated manual entry of data » Use of outdated standard forms » Use of inappropriate software » Creating hard copies of reports 25 Above the Shop Floor… This pile represents over a dozen jobs. How many labor hours to produce this paper? Office Simulation Let’s learn by doing! 28 YESCO Hawaii A New Division 29 YESCO Hawaii Orientation » You are all employees of YESCO Hawaii » Positions to be filled: - Sales - Business Office - Engineering - Material Control - Scheduling - Production/Installation - Process Engineer » We will work in batches of 5 at Sales and 1 everywhere else » We will measure the following - # of orders shipped - # of invoices faxed - # of quote drawings completed - Work in process 30 YESCO Hawaii – Company Policies » Work shift is 10 minutes » Keep busy at all times » The goal is to Install and invoice 14 orders and complete 3 new business quotes 31 YESCO Hawaii Round 1 32 Metrics Scorecard Measures Lead Time Work-In-Process Orders Shipped/Installed Drawings Quoted Invoiced $s Material Costs Labor Costs Overhead Fixed Costs ($5,000) Total Cost Total Revenue Profit / Loss Totals Team 1 Team 2 Team 1 Team 2 Team 1 Team 2 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 33 YESCO Hawaii Round 2 Make some improvements! 34 Metrics Scorecard Measures Lead Time Work-In-Process Orders Shipped/Installed Drawings Quoted Invoiced $s Material Costs Labor Costs Overhead Fixed Costs ($5,000) Total Cost Total Revenue Profit / Loss Totals Team 1 Team 2 Team 1 Team 2 Team 1 Team 2 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 35 LET’S GET LEAN Learn the tools to recreate your WORLD 36 DVD Its all about Time 37 Characteristics of a Lean Process 1. People arranged in process order 2. One-piece flow processes 3. Ergonomically-correct work areas 4. Pull system discipline 5. “Standard operations” defined and implemented 6. Cross-functional, multi-process associates 7. Process intolerant of abnormalities 38 7 Steps for Value Stream Mapping with Swim Lanes 1. 2. 3. 4. 5. 6. 7. Create a macro level flow of process Select a functional area to map Detail the steps Identify NVA and N-NVA steps Analyze the process Develop a future map Develop and implement action plan 39 1. Create Flow of Process stream Break up departments into “swim lanes” “YESCO Hawaii” Value Stream Map of business process Scheduling Material Control Business Office Sales Swim Lane border (divides departments) ©2006 MMTC 41 3. Detail the Steps Process Mapping Guidelines • Gather the information from the actual process - “go see” where the work is being performed • Get the real data versus the theoretical way it should be done or the way people “think” it is done • Use the “experts” (people doing the work) to develop the maps • Use the maps as a microscope on the process to allow you to see where to make improvements 43 Use the Experts… 44 Explanation of Flow Diagram Symbols & Colors D O Describe the process step W Color in: Value Added Non-Value Added Necessary Non-Value Added N T I M E If the step is Non-Value Added, which DOWNTIME waste(s) does it represent? What is the walk/travel distance? How much time does it take to complete the process step? 45 Explanation of Flow Diagram Symbols & Colors I Represents “Inventory” 46 Explanation of Flow Diagram Symbols & Colors Yes or No? Represents a “Decision” 47 Explanation of Flow Diagram Symbols & Colors Connects a process within a swim lane 48 Explanation of Flow Diagram Symbols & Colors Connects steps that cross swim lanes 49 Explanation of Flow Colors Diagram Symbols & Represents electronic work/data transmission 50 Explanation of Flow Diagram Symbols & Colors RAI Represents document Reviews, Approvals or Inspections (RAI) 51 4. Identify NVA & N-NVA Steps N-NVA NVA VA Examples of NVA Activities » Traveling (excess transportation or motion of people or materials) » Inspecting or checking (review-approvalauthorization cycles) » Work reporting (“done right the first time” rule) » Redundant or unnecessary data entry » Supervising » Counting » Reformatting or creating duplicate copies » Filing and file maintenance 53 5. Analyze the Value Stream Map 1. Total each of the different process events Value Added Non Value Added Non Value Added Necessary Delay Approve or Inspect Hand Off Inventory Totals Time Steps 54 5. Analyze the Value Stream Map (using Starbursts) NOTE: Paste a bright green post-it near improvement opportunities that you have identified from you current state value stream map. Write a small description of the waste and how to fix it. STARBURST 5. Analyze the Process Map 2. Identify opportunities to combine steps that occur between two or more people • In order to eliminate handoffs or delays 3. Identify opportunities to perform work simultaneously instead of sequentially • In “parallel” instead of “serially”. What is the earliest a particular work step can occur? • Identify opportunities where work (documents or information) can be delivered to the next person or operation one piece at a time instead of delivering work in a “Batch” • Identify opportunities to build into the process signals or advanced notice to downstream departments to prepare to receive or produce work 56 Parallel vs. Serial Processing 57 5. Analyze the Process Map 4. Identify opportunities to “co-locate” people doing work: • To improve communication • To reduce the effects of handoffs and of transportation distances. 5. Identify opportunities to automate any of the work • Electronically capture and transmit documents (scan-mail) – • Electronically capture and report process events and work status – • Replace manual handoff with an electronic handoff Replace hard copy forms, worksheets, or spreadsheets with electronic versions, accessible from the network Electronically combine several documents into a single database 58 5. Analyze the Process Map 6. Identify problems which if solved will reduce time or error rate 7. Determine whether the entire process is a candidate for “reengineering” 59 6. Develop Future Map Now that opportunities for improvement have been identified through the analysis step, start a new map incorporating the improvements you identified. Remember to take a picture of your before and after states. 60 7. Develop & Implement Action Plan » Create a list of actions » Prioritize the list – Impact-Difficulty Grid » Assign responsibility » Define due dates 61 Impact/Difficulty Matrix Difficulty Easy Hard Impact High Low 62 Sustaining Improvements » Recognize that several follow-up activities may be necessary: – Implementing and refining a measurement or performance monitoring system – Initiating additional improvements or corrections based on the measured results of the improved process » Reconvene Team representatives until the projected levels of improvement have been achieved and sustained for at least three months 63 Exercise – Map the process! Exercise 64 Symbols & Colors for Process Mapping Process Step Same Person Step Between Process Step I RAI Inventory Decision Review, Approve Inspect 65 Lean Tools Fill up your Tool Box! 66 Takt Time is the pace needed to meet customer demand. If you have a Takt Time of two minutes, that Establishing Takt Time the process is means every two minutes completed once. Every two hours, two days or two weeks, whatever your sell rate (customer demand) is your Takt Time. Takt Time = Your Operating Time per Shift Customer Requirement per Shift GOAL: Produce = 60 sec to Demand! 27,600 sec (7.67 hours) 460 orders 67 5S & Visual Management • A proven method used to systematically organize, clean, and standardize the workplace If you can’t do 5S, you can’t do Lean! 68 5S & Visual Management Seiri Saiton Sort Set-In-Order Clear out Configure Seiso Seiketsu Shitsuke Shine Standardize Sustain Clean Conformity Custom 69 Elements of a 5S Program • • • • • Sort - what is not needed, sort through, then sort out; “When in doubt, throw it out!” Set-in-order - what must be kept; make visible and self-explanatory so everyone knows where everything goes Shine - everything that remains. Clean equipment, tools and workplace Standardize - implement best practices to keep the workplace clean and organize Sustain - making a habit of properly maintaining correct procedures 70 What is Standardized Work? • Standardized Work is a method enabling employees to improve their control of operations and measure their performance against documented standards • Performance is optimized by reducing variation and waste in operations by the efficient arrangement of people, products, and machines, thus improving product quality 71 Cellular / Flow Processing • • Arrange people and workspace to achieve one-piece flow Minimizes wastes of: • Defects • Transportation • Overproduction • Inventory • Waiting • Motion • Non-utilized Talent • Extra Processing Single piece flow Pull process control Reduced waste Improved floor space 72 One Piece Flow Consider these conditions for “flow” in the office setting: 1. One piece processing versus “batch” 2. People in process sequence 3. Multi-process work sequence 4. Multi-process skilled people 5. Synchronization of operations (work balance) 73 Poka-Yoke / Mistake-Proofing Poka-Yoke is the removal of all potential causes of error either through design, process, or mistake-proofing devices, to ensure consistent process results Poka-Yoke helps build quality into processes to achieve “Zero Defects” 74 Kaizen • Kai = Change • Zen = Good (for the better) • Kaizen = Continuous Improvement Kaizen has a bias for action! 75 Yesco Hawaii Round 3 Remember to think outside the box! 76 Metrics Scorecard Measures Lead Time Work-In-Process Orders Shipped/Installed Drawings Quoted Invoiced $s Material Costs Labor Costs Overhead Fixed Costs ($5,000) Total Cost Total Revenue Profit / Loss Totals Team 1 Team 2 Team 1 Team 2 Team 1 Team 2 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 77 Customer Service Request – IT Provider Old Process – Average 50 days Define Customer New Process - Average 7 days Waste removed Service Rep order defines order Customer Mgr verifies Customer Service Admin inputs order Prepares form To data base Service Rep Mgr approves Quote No quote Yes Needed? Mgr approves Purchasing quote quotes order Admin inputs to data base Quote above No $8,000? Mgr approval Admin sends Purchasing fills Approval notice order Yes Mgt Board Purchasing fills approval order Account VP Order processing approval Receives and Order processing Signs off Receives and Signs off 78 YESCO Las Vegas Success Story » The business office has reduced Node 5 (last day of labor to date of invoice) from an average of 15 to 20 days to 5 to 12 days for the Exteriors Branch. » The same concepts are being used to streamline the billing process for Interiors eliminating several hand offs and reducing Node 5 as well. 79 YESCO Electronics Success Story… 80 Lending Process – Financial Institution Time spent by Loan Processor – Old Process 10/15% 10/20% 5% 60/75% Adm/clerical General phone Fill in for -filing Inquiries from Other staff -typing Loan Processing members -mailing -gathering data New Lean Process after Kaizen Event 5% 5% Phone inquiries Fill in for Loans only Other staff 90% Loan Processing 81 Keys to Success » » » » » » » Create a sense of urgency Have a vision, communicate it continuously Focus on key process drivers Remove all obstacles to achieve the vision Create short term victories Don’t declare victory too soon Speak with data – – – – – Don’t assume Analyze data – doubt it Make decisions with data Take action based on data Check results 82 The ideal first project… » … is clearly and unambiguously measurable. This is not always possible for administrative Kaizens. » …satisfies a widely-perceived need. » … is a repeatable process. » … is self-contained, not subject to uncontrollable external influence. 83 Administrative Process Improvement » Administrative Kaizens are often discontinuous miniKaizens. » The team meets first to understand the nature of the project and decide what they will need to know. The current state is described. A process map may be developed. » Any information unavailable at the first meeting is provided prior to the second meeting. » The second meeting is generally one day. The project is analyzed and a complete action plan is developed. The plan is implemented and the outcomes are monitored. » If necessary, a follow up meeting is held. 84 The Kaizen Project Team » Team members are selected on a project-byproject basis. » There is a team leader chosen to facilitate and coordinate. The leader is not in charge in the traditional sense. » The team can be comprised of: Subject matter experts in the target area. Others in the same segment of the organization. Individuals from other areas of the organization. This includes technical staff. Individuals from outside the organization. 85 The Kaizen Project Team An open, egalitarian structure is important. When Kaizen project work is underway, organizational position is irrelevant and disregarded. All team members are considered equal within the team. 86 Key Kaizen Tenets » An open atmosphere is critical. Free thinking and contribution are necessary. » Everything is open to question. No assumptions are made. » A Kaizen event is not developing a list of ideas or recommendations to be studied. The outcome is implemented. 87 Now – Recreate that World » » » » » » » Map it – with the experts Study your map Implement changes Celebrate Study and implement more changes Celebrate Repeat, Repeat, Repeat 88 Questions? 89