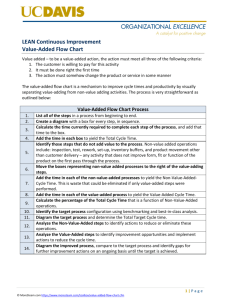

Identifying Value-Added Activities

advertisement

Identifying Value-Added Activities Melissa DeMaso Student of Quality and Supply Chain Management Marriot School Brigham Young University Value-Added Activities Value Analysis Identifying Value-Added Activities Process Mapping Value Added Activities So what is a “value-added” activity anyway? Value-Added An activity is considered value-added when some customer is willing to pay more for the additional output. Examples of value-added components of a product? What’s the potential problem with only considering what the customer considers as value-added? -Cost of production? -Does it effect other functional areas? -Effect on quality? So there’s more …. Value-Added: The difference between the cost of inputs and the value or price of outputs (Price of outputs: price that customers are willing to pay for the goods or service) One equation for value: Value= function/cost Exercise: Using the previous formula, determine the added value in the following situation: Company Y manufactures screwdrivers. After thorough market research, they determine that customers would prefer rubber handles rather than plastic and would even pay $1 more for such a feature. To manufacture, market, and ship the new handles there is an average additional cost of $.60 per unit. Is there an added-value? What would it be? Exercise cont: Using the previous formula, determine the added value in the following situation: Value= $1/ $.60 = 1.67 >1 means there is value-added! Yes, make the rubber-handled screwdrivers! Value Analysis Value Analysis: Examination of the function of parts and materials in an effort to reduce cost and/ or improve product performance. So What’s the Point? The primary objective of value analysis is assess how to increase the value of an item or service at the lowest cost without sacrificing quality. How do you do that? Any ideas? Some ways to increase value at low cost without sacrifice: - increase the functionality or use of a product or service while holding costs constant - reduce cost while not reducing functionality - and increase functionality more than cost. “In such a fast-paced environment, product development must be transformed into a continuous, iterative, learning process focused on customer value.” -Turning New Product Development into a Continuous Learning, David Hughes & Don Chafin Sherwin-Williams’ Dutch Boy Group’s Twist & Pour Revolutionizing house paint packaging! Consumer values: - square container lightweight but sturdy hollow handle snap-in pour spout twist-off lid Company Values: - space-efficient easier to ship and stock additional shelf space Identifying Value-Added Activities One of the best ways to identify value-added activities is to assess if a particular part of a product or process is a non value-added activity. So how do you do that? Is your process more complicated than it needs to be? Value or Non-Value Added? Typical questions to ask: 1. 2. 3. 4. 5. 6. Could a cheaper part or material be used? Is the function necessary? Can the function of two or more parts be performed by a single part for a lower cost? Can a part be simplified? Could product specifications be relaxed and would this result in a lower price? Could standard parts be substituted for non standard parts? “A well-defined lean supply chain is characterized by processes that are considered core competencies by the organization and are supported by qualified suppliers and driven by customer needs.” - Operations Management William J. Stevenson Process Mapping Process mapping Describes processes in terms of the activities within the process and how they relate to each other. Example of Process Mapping So what does that have to do with value-added activities? In addition to value analysis, a top-most effective method of identifying value is process mapping. By continually improving your process, you are becoming more and more competitive in your business performance therefore bettering both you and your customer! Additional Suggested Readings Adding Value or Adding Cost? By: Jones, Christopher. Management Services, Mar1994, Vol. 38 Issue 3, p20-20 Beyond Products: Services-Based Strategy. By: Quinn, James Brian; Doorley, Thomas L.; Paquette, Penny C.. Harvard Business Review, Mar/Apr90, Vol. 68 Issue 2, p58-67 Value chain analysis in consumer focus improvement. By: Zokaei, A. Keivan; Simons, David W.. International Journal of Logistics Management, 2006, Vol. 17 Issue 2, p141-162, 22p Coordinated value mapping process makes Lean effective for manufacturer. By: Levine, Phyllis. Plant Engineering, Feb2006, Vol. 60 Issue 2, p2324, 2p, 2c