Cooling Strategies (PowerPoint)

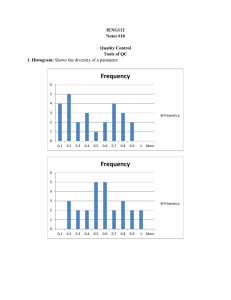

advertisement

21st Century Cooling for Dry Climates For the Napa Valley Wine Technical Group Dick Bourne, WCEC Assoc. Director January 22, 2009 Electricity: Cooling is the Culprit • July peak demand is 35% above January • Cooling causes electricity peaks 7% Load Factor for Residential 22% Load Factor for Non-Residential • Cooling peak reducers - best new peaking plants Western Climates: Issues = Opportunities • Large Diurnal Temperature Swings Issue – Poor Load Factor Opportunity – Thermal Storage • Low Outdoor Humidity Issue – Non-Optimized Equipment Opportunity – Evaporation for Cooling, Radiant Cooling Warm air HOT air WCEC: Who We Are • Part of the Energy Efficiency Center at University of California, Davis • Launched April 2007 • Current staff: Mark Modera, Director Dick Bourne, Associate Director Marshall Hunt, Programs Director Kristin Heinemeier, Senior Engineer Seven Mechanical Engineering Students WCEC: Who We Are • Affiliate Structure Utilities • PG&E, SCE, SMUD, SEMPRA Manufacturers • Delphi, Ice Energy, ICI, Lennox, Munters, NovaTorque, Seeley Intl., Speakman, Thermal Flow, Trane, Viega, VRTX Contracting/Design Firms • Beutler, Davis Energy Group, Timmons Design Engineers State Agencies • CEC, DGS Retailers • Wal-Mart, Target WCEC Goals • By 2030, reduce cooling demand and energy use from 2007 baseline New buildings • Zero cooling peak demand • 50% reduction in cooling energy use Existing buildings • 50% reduction in cooling peak demand • 25% reduction in cooling energy use What We Do • Publicize cooling technologies optimized for hot, dry west Support affiliate alliances and partnerships Address market impediments (e.g. codes and standards) Help bridge commercialization “valley of death” Emerging technology demonstrations • Research and development Identify, conduct and support key R&D • Technology development • Laboratory and field testing • Modeling and analysis • Outreach activities Catalog of energy-efficient cooling systems Website, newsletters, presentations, publications Education – university and professional Current WCEC Activities • Funded Projects CEC - PIER Advanced Cooling Support Program CIEE – State-building technology demonstrations (SDSU and UCSD lab sash project) BERG – Improving the Cost Effectiveness of Radiant Floor Cooling Systems SEMPRA- Energy Performance of Hotel Controls (with CLTC) SMUD –Hybrid OASys Field Test BERG at LBNL – Exhaust Duct Leakage Diagnosis in Multi-Family Buildings EPRI – SEER Review, Status and Recommendations LANEY COLLEGE/NSF – HVAC training SCE • Water Management for Indirect and Indirect-Direct Evaporative Air Conditioning • Water Use by AquaChill evaporative condenser Current WCEC Activities • Projects in Process CEC – Three-Year WCEC Research Support DOE – Development of lab tests for annual savings predictions SEMPRA/PG&E/SCE – Statewide Initiatives (Evaporative Cooling, Hot Dry AC, Fault Detection/Diagnostics) • Newly-Funded PIER Projects Radiant Cooling for Residences Non-Residential Fault Detection Diagnostics Current WCEC Activities • Current Key Activities Western Cooling Challenge – announced 6/5/08 Water Initiative – recent ASHRAE presentation DOE SEER update • Current Technologies of Interest Building-Integrated Cooling Swimming-Pool Heating WicKool Dedicated Outdoor Air Systems WCEC Technology Portfolio • Most technologies appropriate for new and retrofit Rooftop units Evaporative cooling technologies • Hybrid evaporative/vapor-compression equipment • Water-cooled condensers Swimming-pool-based air conditioners Thermal distribution performance Night-sky radiative cooling • Some opportunities unique to new construction: Low-cost chilled water storage Radiant floor cooling Example Technology: DualCool • Accessory system for RTUs • Pre-cools condenser and A C ventilation air D • DOES NOT add moisture to indoors • 25-30% energy and demand savings B SYSTEM SCHEMATIC A - High quality condenser air pre-cooler B - Pump & copper supply/return piping C - Ventilation air precooling coil D - Controls Example Technology: Roll-Out Radiant Floor • Prior cost $6-7/ft2 • Rollout cost ~$2/ft2 • Full-scale installation at Wal-Mart store Example Technology: Radiant Floor Benefits • • • • Reduces latent cooling and blower energy Facilitates non-compressor cooling Projected savings 60-65% Projected demand reduction 45%+ Example Thermal Storage Technology • Residential/Commercial Swimming Pools Night-time cooling (non-refrigerative) makes pool water available for day-time low-temperature heat rejection • 20-40oF reduction in refrigerant condensing temperature • 20-50% improvement in EER – higher at peak conditions Rejected heat serves useful function • Eliminates/reduces gas consumption for pool heating Power Draw [KW] Energy Used on Peak Day of Cooling 4.5 4.0 3.5 3.0 2.5 2.0 1.5 1.0 0.5 0.0 Existing Pool only Pool + Cool Tower 0 4 8 12 Hour 16 20 24 WCEC Market Activities • Demonstrations Integrated retrofits for strip malls Technology demonstrations on state-owned buildings • Policy and Market Drivers Western Cooling Challenge Hot, Dry Air Conditioners Water Initiative • Water management for evaporative air conditioning DOE • SEER regional standards • Lab tests for annual savings predictions Western Cooling Challenge • Target Market: Rooftop Units (RTUs) with 3 – 30 ton capacity (>500-unit production capacity) RTUs cool 70% of non-residential floor space in the Western US • Target Performance: 40% reduction in energy use and peak electricity demand • Reward Structure: MOUs w CA IOUs and SMUD for incentive programs – Retailer program sponsorship Western Cooling Challenge: Schedule January 2009 Laboratory testing of WCC entries can begin June 2009 Field testing of WCC entries can begin January 2010 Shipments of WCC-compliant products can begin New Indirect Heat Exchangers Coolerado • Unique multi-stage indirect design • 90%+ effectiveness, balanced flow • 250 cfm per module, 10” high, 20” long, 19” wide • Used in Coolerado & Desert Cool Aire prototypes New Indirect Heat Exchangers HyPak • High-speed production process • 80%+ effective in lab test • Delivered 4.3 tons for 2’ width • Many other applications Example Market Issue: Water Initiative • Impediments to water-based cooling On-site water use Equipment maintenance • Successful water-based systems for buildings Cooling towers Pressurized domestic water Pools Irrigation • Water conservation Techniques exist Not optimized for small-scale evaporative cooling Evaporative Cooling: Water Use Metrics • Evaporative Cooling Water Use Cooling potential = mass of water * heat of vaporization Potentially as low as 1.37 gallons/ton-hr • Maintenance Water Use Rule of Thumb: 2/3 evaporation, 1/3 maintenance Large Impact of Water Quality • Indirect Water Consumption for Electricity Generation Enormous range of values - 0.1-72 gal/KWh Water Use for Condenser-Air Pre-Cooling • Analysis Technique Calculate change in EER with respect to condenser air temperature • Relatively linear • 1-2% change per oF Calculate condenser temperature change per unit of water evaporated Use EER change to calculate extra cooling delivered for the same electricity consumed Example Market Issue: Water Issue Resolution • Roles for the WCEC provide “institutional memory” on water issues • water-use yardsticks access large cadre of water scientists at UCD pursue water conservation solutions • save rain runoff for cooling • irrigate w/flushed water • night-sky water cooling Wine Industry Opportunities • • • • Evaporative condensing and pre-cooling Pre-cooled ventilation air (e.g. Fetzer) Thermal storage (wine is ideal!) Radiant cooling to reduce blower power (may need desiccants in high humidity areas) • CHP (e.g. Vineyard 29) • Others? WCEC Mission Summary “Partner with stakeholders to identify technologies, conduct research and demonstrations, disseminate information, and implement programs that reduce coolingsystem electrical demand and energy consumption in the Western United States.” http://wcec.ucdavis.edu/ Mark Modera mpmodera@ucdavis.edu