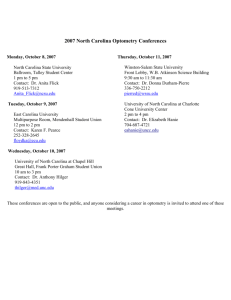

Geography of the Industry in North Carolina

advertisement

BANKING IN NORTH CAROLINA INTRODUCTION The banking and finance industries have existed for thousands of years, and lie at the heart of the modern economy. One of the leading service-economy industries, banks and financial institutions have gained employment and revenue steadily for decades. Yet even in the midst of an American transition from a manufacturing economy to a service economy, the industry faces substantial challenges and is undergoing a major transition. Advancements in computer and information technology have allowed financial transactions and services to be carried out faster than ever before. Changes in state and national regulation have opened new horizons for American banks, but have also brought firms in close competition. Globalization and changes in state and national regulation have allowed new market opportunities for banks, but have also brought new international competitors. As banks and financial institutions adjust to the new rules of competition, new players will emerge to push the industry forward. Description of the Industry The banking and finance industries, also known collectively as the financial services industry, includes firms and institutions that are responsible for carrying out financial transactions or facilitating financial transactions through services provided. A financial transaction, in this context, is defined as the "creation, liquidation, or change in ownership of financial assets."1 Firms involved include commercial banks, investment banks, mortgage brokers, securities brokers, asset management firms, securities exchanges and trusts, as well as other unique types of financial organizations and vehicles. Firms in the industry generally carry out two different types of financial transactions, or provide services for these transactions:2 Raising funds by taking deposits and/or issuing securities and using those funds to make loans and/or purchase securities. Firms engaged in these activities generally seek to channel funds from lenders to borrowers and transform or repackage the funds with respect to maturity, scale and risk. This activity is known as financial intermediation. Pooling risk by underwriting insurance and annuities. Establishments engaged in this activity collect fees, insurance premiums, or annuity considerations; build up reserves; invest those reserves; and make contractual payments. Fees are based on the expected incidence of the insured risk and the expected return on investment. Providing specialized services to individuals and firms to facilitate or support either of the above types of transactions. TABLE 1 - NORTH CAROLINA'S TOP BANKING EMPLOYERS, 2007 Company Primary NAICS Codes1 No. of Locations, 100+ Employees2 Approx. NC Employment Total Sales (US$ mil.) Approx. Number of Branches2 1 Bank of America Corp. 523, 55 2 6,700 1 trillion+ 200 2 Wachovia Corp. 522-523, 55 5 5,546 520,880 500 3 Branch Banking & Trust Corp. (Laureate Capital LLC, Regional Acceptance Corp., Sheffield Financial LLC, Stanley Hunt Dupree & Rhine, Sterling Capital Mgmt. LLC) 522-523, 525, 532, 55 13 1,520 109,170 350 4 Vanguard Group 523 1 800 300 NA 5 Burlington Worldwide Apparel 315 1 700 300 NA 6 SunTrust Bank 522 1 700 NA 200 7 AON Consulting 524 1 650 300 NA 8 First Citizens Bancshares, Inc. 522-523, 55 5 625 90 300 9 RBC Centura Banks Inc. 522, 55 2 552 1,500 200 10 First Charter Corp. 55 1 480 4,232 50 11 Wake County Human Svc. 525 1 480 35 NA 12 Americredit Financial Svc. Inc. 522 1 430 NA NA 13 State Employees' Credit Union 522 2 400 110 200 14 Greensboro War Meml. Auditorium 522 1 400 75 NA 15 Federal Reserve Bank 522 1 370 NA NA 16 Regions Financial Corp. 522 2 300 NA 10 17 ACS 525 1 300 35 NA 18 Deluxe Financial Svc. 522 1 300 300 NA 19 United Chemi-Con Inc. 334 1 300 8 NA 20 Volvo Commercial Finance 522 1 300 NA NA 21 LSB Bancshares Inc. 522-523 4 279 300 35 22 First National Bank of Shelby 522 2 250 300 3 23 Shaw University 611 1 250 NA NA 24 FNB United Corp. 522, 55 3 240 1,102 25 25 Cooperative Bankshares Inc. 522 2 225 208 20 1. North American Industrial Classification System (NAICS) Primary NAICS Codes: 522 (Credit Intermediation), 523 (Securities and Other Financial Investments), 525 (Funds, Trusts, and Other Financial Vehicles) Other NAICS Codes: 315 (Apparel Mfg.), 334 (Computer Equipment Mfg.), 524 (Insurance Carriers), 532 (Rental and Leasing Services), 55 (Company Management), 611 (Educational Services) 2. Only establishments over 100 employees were tallied for this table. Number of branches is included to provide relative sizes of banks, but employees of these branches are not tallied. Source: Reference InfoUSA, 2/07 The Furniture Industry in NC INTRODUCTION The traditional North Carolina furniture industry has been experiencing drastic changes in the past decade. Competition from countries like China and the rising imports of furniture into the United States have led many furniture manufacturers in the state to shut down plants and lay off workers. Firms in the industry are being forced to rethink their corporate strategies in order to remain successful. More importantly, the industry's transformation into a global one raises many questions about government action and government policy. Should the government be intervening more aggressively in order to keep the industry, particularly within North Carolina, from withering? General Industry Structure Most consumers have a sense of what a piece of furniture constitutes, and yet the industry is a fairly complex industry, due partly to the diversity of materials used to create furniture and partly to the broad range of furniture used in our homes, businesses and institutions. There are three main types of materials used to make furniture: Wood (which comes from sawmills and the forestry industry) Metal (which comes from mining/metals) Plastic (which comes as an output of the chemicals/plastics industry) In addition, furniture is often divided into several different types, depending on the type of furniture used: Home furnishings consists of most furniture used in the home; examples would be bedroom or kitchen furniture like beds and tables. Office furniture includes functional furniture used around the office or workplace; this includes desks, filing cabinets, and cubicle walls, among others. Institutional furniture constitutes furniture used in a variety of institutions, from schools to prisons to government buildings. FURNITURE IN NORTH CAROLINA History and Development The furniture industry in North Carolina has been a major player in the state's economy for over a century. The origins date back as far as the seventeenth century when artisans of English ancestry began to settle across the state, producing simple yet functional furniture on a small scale. Early industrial entrepreneurs and developers focused on the Piedmont section of North Carolina, especially the city of High Point. The area was extremely well-suited for the furniture industry because of an abundant wood supply from numerous hardwood forests, above-average railway and highway transportation opportunities and the availability of cheap labor.1 By the 1980s, High Point had earned the nickname "The Furniture Capital of the World," and employment peaked at around 90,000 people in 1990. High Point hosted its first regional furniture trade fair in 1909; these events gradually evolved into High Point Market, an internationally-renowned furniture trade fair. Unfortunately for North Carolina, the furniture industry began to feel the effects of increased foreign competition during the late 1990s. As competition increased and profits dwindled, many North Carolina companies either went out of business or were forced to consolidate by closing factories, laying off employees and importing products from overseas. Yet North Carolina still maintains a strong presence in this industry, with about 52,400 active employees. The bi-annual High Point furniture market alone draws more than 85,000 people to North Carolina every six months, and contributes around $1.2 billion to the economy each year.2 An estimate from 2004 indicated that the industry contributes around $2.8 billion annually to the economy.3 Geography of the Industry in North Carolina Geographically, the industry remains concentrated in certain areas, especially the Piedmont Triad. Catawba County (which includes Hickory) has the highest employment in the industry with more than 11,000 people working in furniture manufacturing. Three additional counties (Caldwell, Guilford and Randolph) all employ more than 4,000, and two more (Alexander and Davidson) employ more than 3,000. Together, these six counties make up 63% of the entire state's employment in the furniture industry.4 Key cities include High Point, Thomasville, Greensboro and Winston-Salem, among others. Key Players Thomasville Furniture and Broyhill Furniture Industries, both owned by Missouri-based Furniture Brands International, are two of the most important furniture companies in North Carolina. Furniture Brands International is ranked as one of the top furniture companies in the United States, with sales of $2.4 billion in 2006.5 Klaussner Corporation, based in North Carolina, was ranked the fourth largest furniture supplier in the country as of 2004, though as a private company they do not release sales figures.6 Similarly, Lexington Home Brands had estimated U.S. sales of $167.3 million in 2006, and ranked as number 16 on the top 25 furniture sources list published by Furniture Today in 2004. Most of these companies are located within the Piedmont Triad region (primarily Guilford, Randolph, and Davidson counties), in the north central region of the state. TABLE 1 - TOP FURNITURE EMPLOYERS IN NORTH CAROLINA, 2007 Company 1 Furniture Brands Int'l Inc. NAICS Codes 1 No. of NC Total Sales Plants Employment (US$ mil.) 3371, 3372 26 4,999 1,017 2 Klaussner Furniture Industries 3371 1 3,700 302 3 La-Z-Boy Inc. 3371 20 3,472 710 3371, 442 3 1,400 900 3371 4 1,034 411 3371, 442 2 730 335 7 Mitchell Gold & Bob Williams 3371 2 701 35 8 Leggett & Platt Inc. (Collier- 3371, 321, 425 3 657 392 3371 1 650 300 10 Marsh Furniture Co. 3371 2 643 300 11 Craftmaster Furniture Corp. 3371 3 591 50 12 Hancock & Moore Inc. (Councill 3371 5 587 148 (Broyhill Furniture, Drexel Heritage Furniture, HBF, HDM Furniture, Henredon Furniture, Hickory Chair Co., Lane Furniture, Laneventure Inc., Maitland Smith LA Barge, Pearson Co., Thomasville Furniture, Thomasville Upholstery) (American Drew Furniture, Clayton marcus Co., England, Hammary Furniture, Kincaid Furniture, La-ZBoy Furniture Galleries, Lea Industries, Pennsylvania House 4 Ethan Allen Inc. (Ethan Allen Galleries) 5 Stanley Furniture Co. Inc. 6 Lexington Home Brands (Lexington Furniture) Kenworth Co.) 9 Progressive Furniture Warehouse Craftsmen, Jessica Charles) Company NAICS Codes 1 No. of NC Total Sales Plants Employment (US$ mil.) 13 Mc Creary Modern Inc. 3371 3 533 308 14 Classic Leather Inc. (St. Timothy 3371 2 530 110 3371 1 500 300 3371 4 471 355 17 Hughes Furniture Industries 3371, 3372 2 465 50 18 Vanguard Furniture Co. Inc. 3371 2 450 79 19 HNI Corp. (Hon Co., Maxon 3372 2 445 110 3371 8 422 424 21 Kewaunee Scientific Corp. 3391 1 400 74 22 Barcalounger Co. 3371 1 396 75 23 Chromcraft Revington Inc. 3371 5 377 19 3252, 32615, 425 3 375 225 25 Lee Industries Inc. 3371 2 370 78 26 Kohler Co. (Baker Furniture, Canac 3371 6 350 158 3371 1 350 75 3371, 442 4 347 17 Chair Co.) 15 Caughan-Bassett Furniture (Elkin Furniture Co.) 16 Sherrill Furniture (Hickory-White, HWS) Furniture) 20 CV Industries Inc. (Century Furniture, Expressions Corp., Shuford Furniture) (Cochrane Furniture, Silver Furniture, Sumter Cabinet) 24 Hickory Springs Mfg. Kitchens US, Dapha Limited) 27 Kroehler Furniture Co. 28 Bassett Furniture Industries (Bassett Furniture, Bassett Upholstery, Weiman Co.) Company 29 Norwalk Furniture (Hickory Hill NAICS Codes 1 No. of NC Total Sales Plants Employment (US$ mil.) 3371 1 312 NA 3371 3 309 19 3371, 442 4 307 73 3379 1 300 1,470 3371, 321 1 300 75 321 1 300 75 3371, 3372 2 300 70 36 EJ Victor Furniture Inc. 3371 1 300 15 37 Southern Furniture Co. (Conover) 3371 1 280 35 38 Renaissance Stone 3371 1 275 35 39 March Furniture Mfg. Inc. 3371 1 250 75 40 Wesley Hall Inc. 3371 1 250 75 41 Dar/Ran Furniture Industries 3372 1 250 35 444 1 250 35 42344 1 250 NA 3371, 42383 45 226 82 321 1 200 300 3372 1 200 75 3372, 4532 5 200 59 48 King Hickory Furniture Co. 3371 1 200 35 49 Motion EAZE 3371 1 200 35 Furniture Corp.) 30 Hekman/Woodmark (Hekman Furniture, Woodmark Originals) 31 Bernhardt Furniture Co. 32 Sealy Corp. 33 Arden Co. 34 Sierra Pacific Industries (ECMD Inc.) 35 High Point Furniture Industries 42 Zickgraf Enterprises Inc. 43 American Greetings Corp. (AGI Schutz) 44 Sally Beauty Holdings Inc. 45 CHF Industries Inc. 46 Clayton Homes Inc. (Schult Homes) 47 Office Depot Inc. Company NAICS Codes 1 No. of NC Total Sales Plants Employment (US$ mil.) 50 Key City Furniture 3371 1 200 15 51 Newell Rubbermaid Inc. 3379 1 200 NA (Levolor/Kirsch) 1. North American Industrial Classification System (NAICS) Primary NAICS Codes: 3371 (Household and Institutional Furniture), 3372 (Office Furniture), 3379 (Other Furniture) Other NAICS Codes: 321 (Wood Product Mfg.), 3252 (Resin, Synthetic Rubber, and Artificial Fiber Mfg.), 32615 (Urethane and Other Foam Product (exc. Polystyrene) Mfg.), 3391 (Medical Equipment and Supplies Mfg.), 42344 (Other Commercial Equipment Merchant Wholesalers), 42383 (Industrial Machinery and Equipment Merchant Wholesalers), 425 (Wholesale Electronic Markets and Agents and Brokers), 442 (Furniture and Home Furnishings Stores), 444 (Building Material and Garden Equipment and Supplies Dealers), 4532 (Office Supplies Stores) Source: Reference InfoUSA, 2/07 Hog Farming In NC INTRODUCTION Hog farming represents an integral part of the broader industry that entails the rearing, butchering, processing, and selling of hogs, known as the pork production industry. Pork production consists of six separate stages: research and development, hog farming, meat processing, finishing and packaging, product distribution, and retail. For North Carolina, hog farming itself is the most important of these value chain links. The farming stage also consists of six different areas, breeding, gestation, farrowing, weaning, nursery, and grow finishing. North Carolina firms participate in all of these links. Astoundingly, hog farming in North Carolina is valued at well more than US $1 billion. Although pigs have been an historical part of the state's agriculture, it is in the 1990s that the sector has experienced exponential growth. Within a decade, the hog population jumped, from around 2.6 million in 1988 to over 8 million in 1997.1 One of the most interesting features to note is that the increase in the total population of hogs was accompanied by a concomitant decline in the total number of hog farms. In 1986, there were 15,000 farms with at least one head of hogs in the state. By the year 2006, there were only 2,300 such farms remaining. 2 In this section we highlight facets of these trends - the consolidation of farms with the increase in the number hogs - along with several social, political, and environmental concerns the industry faces. HOG FARMING IN NORTH CAROLINA As of the most recent Agricultural Census, in 2002, North Carolina ranks as the second-largest hog farming state in the country, after Iowa.3 Other leading hog farming states are Minnesota and Illinois. Almost sixty percent of the U.S. hog inventory is concentrated in these four states.4 The majority of the hog industry in the state is located in the southeastern region of North Carolina, particularly in the counties of Duplin, Sampson, Bladen, and Robeson (see Map). The timeline below highlights the growth and changes within the industry since 1980, and the political and social steps government, labor and non-profit groups have implemented to affect change in the governance and regulation of the industry. 1980: North Carolina hog farms range between 10,000 and 25,000 hogs in size. 1985: North Carolina ranks 7th nationally in hog production. 1991: North Carolina Senator Wendell Murphy co-sponsors legislation that exempts large-scale hog farms from local zoning regulations. 1992: Smithfield Foods, Inc. opens the world's largest meat processing plant in Bladen County, North Carolina. 1995: North Carolina Senate passes Bill 1080, the Swine Farm Siting Act, requiring new swine houses or lagoons to be located at least 1,500 feet from an occupied residence, at least 2,500 feet from any school, hospital, or church and at least 100 feet from any property boundary. 5 1995 (June 21): The lagoon at Ocean View Farms in Onslow County, North Carolina overflows dumping over 20 million gallons of hog waste into the New River causing massive kills and spurs environmental debate. 1996: President Clinton signs the Freedom to Farm Act in an attempt to cut federal-farming subsidies. 1997: The Clean Water Responsibility Act6, part of Bill 515, places a moratorium on the construction of farms with more than 250 hogs or the expansion of existing large farms in the state of North Carolina. 1998: North Carolina's hog population rises to 10 million from 2 million in 1992. 7 1999: Hurricane Floyd hits North Carolina, flooding hog waste lagoons and contaminating the water supply.8 1999: Renewed moratorium on "lagoon-farms"; there are no limits on farms using environmentally superior technologies. 2000: The Smithfield Agreement: Smithfield Foods and Premium Standard Farms (PSF) entered into an agreement with the Attorney General of North Carolina to fund environmentally superior technologies (ESTs) for hog waste management. Researchers at North Carolina State University are charged with the technology determinations. 2002: Frontline Farmers joins the Smithfield Agreement. 2003: North Carolina Governor Mike Easley successfully calls for a four-year extension of the moratorium on the construction of hog farms in eastern North Carolina. 9 2005: Environmental Defense and Frontline Farmers draft a plan, which calls for elimination of lagoons in North Carolina. The plan would gain sponsorship by Representative Carolyn Justice and becomes Bill 1532, the Clean Hog Farms Act of 2005. 2006: The Clean Hog Farms Act of 2005 is altered, becoming Bill 1730 the Clean Hog Farms Act of 20052, creating a cost-share program for farmers who volunteer to place ESTs on their farms. Despite this change, the bill does not make it through the General Assembly of North Carolina. 2006: The Smithfield Agreement concludes. Researchers determine that none of ESTs evaluated are economically feasible for existing farms. Five, though, would be economically feasible for new farms. 2006: North Carolina State University is awarded a $75,000 grant intended to spur the development of byproducts from two of the leading ESTs. The project will generate value-added products from hog waste and evaluate the economic potential of the products to generate new income for farmers. 2006: Smithfield Foods and Premium Standard Farms agree to $810 million merger. 2006 (November): A two day walk-out by workers at Smithfield Foods' Tar Heel, North Carolina plant was met with the company meeting with a group of elected workers to negotiate a settlement to halt the wholesale firing of immigrant workers. 2006 (December 2): More than 600 protestors from various labor unions, religious organizations, and activist groups boycotted Smithfield Foods products at 11 North Carolina Harris Teeters, a North Carolina based company. The protest, entitled North Carolina Statewide Day of Action, was to show support for the workers at Smithfield's Tar Heel, North Carolina plant. TABLE 1 - TOP HOG FARMING EMPLOYERS IN NORTH CAROLINA, 2007 Company 1 Premium Standard Farms 2 House of Raeford Farms Inc. 3 Smithfield Foods Inc. Primary NAICS No. of NC Total Sales Codes Plants Employment (US$ mil.) 311611 1 1,400 750 4244 1 1,000 300 311611, 1121 3 730 375 311612 1 578 300 1122 1 500 75 1 (Murphy-Brown, Stadler's Country Hams) 4 Con Agra Snack Foods 5 Maxwell Foods Inc. 6 Carolina By Products 311612 3 265 145 7 Martin Wholesale Meats 311611 1 150 75 8 Martin's Pork Products 311612, 4244 2 130 335 9 WolfsonCasing Corp. 311612 1 110 35 10 Carolina Packers Inc. 311611 1 100 15 10 Pork Co. 311612 1 100 35 1. North American Industrial Classification System (NAICS) Primary NAICS Codes: 311611 (Animal (Except Poultry) Processing), 311612 (Meat Processed from Carcasses) Other NAICS Codes: 1121 (Cattle Ranching and Farming), 1122 (Hog and Pig Farming), 4244 (Grocery Wholesalers) Source: Reference InfoUSA, 2/07 Textiles in NC INTRODUCTION The textile and apparel industries have traditionally held a fundamental role in North Carolina's economy, providing thousands of jobs and revenue for local economies. In one sense, the industry is easy to define - the creation of fabric or cloth out of original fibers, using mechanical or chemical processes. Traditionally, most people think of textile products as feeding directly into apparel. Yet textiles & apparel is an expansive industry, with textile products showing up in a variety of places, from construction materials to air filters, from automotive fabrics to upholstered furniture. Specifically, the industry can be broken down in a number of different ways, including: By fiber type (including natural fibers like cotton and wool, and synthetic fibers like nylon) By fabric production process (including using yarn in knitting or weaving, or using nonwoven processes) By fabric finishing process (including unfinished fabrics, coated fabrics, and a variety of other treatments) By end product use (including apparel products, but also including medical products, construction products, automotive products, and a host of other end uses) North Carolina's textile industry is at a crossroads. In order to maintain their leadership as a provider of textiles in the global economy, the industry is facing several key decisions in a new structurally changed economy and business environment. Although they enjoyed for decades the status as a leading manufacturing state, producing textile materials for international and domestic markets, increased competition, technological advancement, and the United States' shift to a service-based economy have all left an indelible impact on the industry. In this section we provide a snapshot of historical configurations and key trends - such as technological innovations, labor relations, and policy changes - which are mapping the future of the industry and how North Carolina firms navigate the rapidly changing terrain. TEXTILES IN NORTH CAROLINA Decline in North Carolina Textiles and Apparel Industries since 1996 This section highlights important industry developments over the last fifteen years in the state of North Carolina. We see how such factors as an overall decline of textiles and apparel and the development of an increasingly fragmented and dispersed industry have affected the state in key ways. The overall decline of the industry is witnessed by the precipitous drop in factories and jobs that was brought on by structural changes in the global economy. In 1996, there were 2,153 textile and apparel plants in North Carolina employing 233,715 people. By 2006, there had been a 40% decline in the number of plants, to 1,282 plants, and a 65% decrease in employment to 80,232 workers (see Table 2a). The reasons for this decline are many, but four principal themes can be discerned: 1. 2. 3. Emergence of "buyer-driven" lead firms (retail) in global apparel and textile value chains1 Shifts in sourcing patterns of lead firms (retailers) Rise in the manufacturing capabilities of firms globally 4. Global quota phase-out of the MFA (Multi-Fiber Arrangement) regime in 2005 has led to loss of trade protection formerly enjoyed by US textile and apparel companies and exposed them to the rigors of global competition1 As the second-largest textile state and the third-largest apparel state in the United States in terms of employment, North Carolina has been the hardest hit in terms of job losses and plant closings. Over a twelve month period ending in May 2006 the state lost close to 7,000 jobs, more than double from the next most comparable state in textiles, Alabama, with 2,800 job losses.2 Although we have seen a drastic decline in the textile industry, the apparel industry has fared much worse, experiencing a 70% decline in jobs and 55% of plants from 1996 to 2006. The textile industry by comparison has only lost 63% of jobs and 32% of plants from 1996. However, the textile industry (NAICS 313 and 314) is almost three times bigger than the apparel industry (NAICS 315) in North Carolina, and employs more than 59,000 workers, accounting for 10.7% of all manufacturing employment. Apparel jobs number just over 20,000 in comparison. With the decline in the bulk numbers of factories operating in the state, one segment of the industry that is growing is North Carolina firms exporting intermediate goods that overseas firms are turning into final products. 14% of North Carolina exports fall within the textile and apparel industry. These exports include both finished goods that are being sold abroad and intermediate goods that firms' plants in other countries will work on. For example, the percentage of North Carolina exports made up of yarn & fabric products is on the rise, while the share of apparel products is on the decline. This change is partly explained by the rising skill levels of global suppliers who can do more and more finishing work, meaning that companies will export more fabric products that suppliers will then turn into apparel. This is shown through the form of foreign direct investment (FDI) into lower-wage and lower skill countries that are nonetheless moving into higher-valued activities within the industry. This is witnessed through these countries receiving the majority of both yarn and fabric exports from the United States. Instead of sending almost finished jeans to, for example, such countries as Honduras or Costa Rica where only final stitching is required, now companies are starting to send them unfinished denim. TABLE 1 - NORTH CAROLINA'S TOP 50 TEXTILE & APPAREL EMPLOYERS, 2007 1 Hanesbrands Inc. (National Textiles LLC) 313-315 15 4,530 1,049 2 International Textile Group (Burlington Worldwide Apparel, Burlington Industries, Burlington Menswear, Cone Mills Corp., Cone Denim LLC, Cone Jacquards) 313-315 10 4,046 1,311 3 Unifi Inc. 313-314 8 3,588 781 4 Collins & Aikman Corp. 313-315 5 2,798 635 5 VF Corporation (VF Jeanswear LP, Lee Apparel Co.) 315 4 2,619 335 6 American Real Estate Partners (West Point Home Inc.) 313 1 2,500 750 7 Cerberus Capital Management LP (Guilford Mills) 313 5 2,221 611 8 National Spinning Co., Inc. (Caron International) 313 4 2,010 410 9 Renfro Corp. 315 1 1,500 NA 313 6 1,389 726 313-314 17 1,378 264 12 Kayser-Roth Corp. 315 6 1,270 187 13 Carolina Mills Inc. 313-315 7 1,096 203 315 2 1,075 70 15 Royal Home Fashions (Croscill Inc., Richmond Yarns Inc.) 313-314, 423 4 1,070 440 16 Cluett American Corp. (Gold Toe Brands Inc., Moretz Inc.) 315 3 1,012 37 17 Stonecutter Mills Corp. 332 1 1,000 NA 313, 315, 4539 5 857 145 313 4 813 383 10 Coats North America (Coats & Clark, Inc.) 11 Parkdale Mills (Magnolia Manufacturing) 14 International Legware Group (Ellis Hosiery Mills Inc., Neuville Industries Inc.) 18 Delta Apparel Inc. (Fun-Tees Inc., MJ Soffe Co.) 19 Patriarch Partners LLC (Galey & Lord Industries Inc., Swift Galey) 20 Ramtex Inc. 313 1 800 75 313-314 4 769 140 313, 81149 5 753 127 23 Dak Americas LLC 313 1 700 300 24 Springs Industries Inc. (Charles D Owen Mfg. Co.) 313 1 700 300 25 Highland Mills Inc. 315 1 600 35 26 Valdese Weavers Inc. 313 2 586 301 313, 551 6 562 383 28 Ethan Allen/Maiden Site 313 1 550 300 29 Clayson Knitting Co. 315 2 550 150 30 Frontier Spinning Mills 313 2 550 150 313-314 2 549 NA 313-314, 4239 6 536 353 33 Interface Fabrics Corp. 314 2 501 81 34 Mc Creary Modern Inc. 337 1 500 300 35 Ronile, Inc. (Gulistan Carpet) 314 1 500 300 36 Dan River Inc. 314 1 500 75 37 Huffman Hosiery Mills Inc. 315 1 500 75 313, 326 2 490 75 313-314, 4232 5 462 65 40 Jockey International Inc. 315, 4539 2 454 105 41 Berkshire Hathaway Inc. (Fruit of the Loom Inc., Shaw Industries Inc.) 315, 4422 2 450 335 315 2 450 105 21 R.L. Stowe Mills Inc. 22 Glen Raven Inc. 27 Ruddick Corp. (American & Efird Inc.) 31 Fab Industries Inc. (Mohican Mills Inc., Salisbury Manufacturing Corp.) 32 Joan Fabrics Corp. 38 Klaussner Furniture Industries (Prestige Fabricators Inc.) 39 Leggett & Platt Inc. (Cumulus Fibres Inc., Hanes Dye & Finishing, Hanes Narrow Fabrics, Iredell Fiber Inc. 42 Kentucky Derby Hosiery Co. 43 Schneider Mills Inc. 81149 1 450 75 44 Mortex Apparel 315 3 450 65 45 Copland Fabrics Inc. 313 1 440 35 46 Polymer Group Inc. (PGI Nonwovens Division) 313 3 425 335 47 Perry Manufacturing Co. 315 1 400 300 48 Outer Banks 314 1 400 75 49 Phantom USA Inc. 315 1 400 75 50 Mo Caro Indtries 313 1 400 8 1. North American Industrial Classification System (NAICS) Primary NAICS Codes: 313 (Textile Mills), 314 (Textile Product Mills), 315 (Apparel Mfg.) Other NAICS Codes: 326 (Plastics and Rubber Products Mfg.), 332 (Fabricated Metal Product Mfg.), 337 (Furniture Mfg.), 423 (Durable Goods Wholesalers), 4232 (Furniture and Furnishing Wholesalers), 4239 (Misc. Durable Goods Wholesalers), 4422 (Home Furnishings Stores), 4539 (Misc. Store Retailers), 551 (Company Management), 81149 (Misc. Personal and Household Goods Repair and Maintenance) Source: Reference InfoUSA, 2/07 Information Technology in NC The information technology industry has grown by leaps and bounds in recent years, fueling the American economic boom of the 1990s and subsequent growth and development. In the process, it has become a part of business in nearly every major industry, from textiles to banking, from furniture to biotech. As globalization gathers speed, IT is also rapidly gaining ground around the world, as more and more people and places connect every day to the global information network. Yet with all the excitement of millions of new Internet users, however, many neglect to understand the dynamics of the industry. While the spread of IT provides IT with tremendous market opportunities, the industry faces renewed challenges of industrial competition, regulation, and resources that it must overcome to succeed. General Industry Structure The information technology (IT) industry can be broadly defined as the sector of the economy providing the means to transmit, store and process data in electronic forms. In practice, the industry can be hard to define, in part because some products in the industry (for example, semiconductors) serve as inputs both to multiple segments of the industry and to other industries. In other cases, voice data (as in telecom) and electronic data (as in computer information) are considered to be separate. This categorization includes a variety of sectors, including both computers and computing, networks and technology solutions, and telecommunications. IT covers a set of manufacturing and service activities, including: Semiconductors: This sector encompasses the development and production of a variety of chips that serve as inputs for the hardware assembly and telecommunication industries, and also serve as components of a variety of non-IT consumer durables. Hardware: Hardware covers all hardware assembly (including personal computers, servers and workstations), along with manufacturing of peripherals, networking equipment, storage and other components. Software: This sector includes the development of general operation systems and application software, along with more customized, business-specific IT solutions. IT/Telecom Services: IT Services include companies that produce services to the IT and telecom industries, including wireless solutions, systems integration, software development, installation, and support. This sector includes consulting services. INFORMATION TECHNOLOGY IN NORTH CAROLINA Information technology (IT) is one of the largest and most important industries located in North Carolina, employing more than 87,000 people in 2006 (see Table 2a). North Carolina's strengths in this industry lie primarily in semiconductors, hardware, and software. Even after the major setbacks in employment, nearly 65,000 people were employed in those three segments.1 North Carolina does, however, serve as home to companies that are operating in every sector of the industry, including IT/telecom services. Key Players Within these links, North Carolina's strength lies largely in manufacturing. Manufacturing remains a critical component of the North Carolina IT industry, still employing more than 30,000 people. The major players in the field that are located within North Carolina cover the entire manufacturing chain, from semiconductor manufacturing to hardware assembly and beyond. Some key examples: RF MicroDevices, a leader in the production of analog semiconductor chips and a beneficiary of the booming market for wireless technologies. Flextronics International, which provides a comprehensive set of R&D and logistical services to tap the capabilities of its semiconductor fabricators, providing both chips and comprehensive integral packages. Cisco Systems and Solectron, global leaders in the fields of storage and networking components, which focus their North Carolina activities on assembly of manufactured products. IBM, whose North Carolina operations rank second among U.S. states and include a highly profitable server division. North Carolina has also sought actively to attract new semiconductor and hardware businesses to the state. Within semiconductors, while North Carolina has offered incentives to smaller semiconductor manufacturers to build and expand operations within the state, it has been unable and unwilling to offer the larger capital incentives needed to attract the larger global players in this industry. This is especially noticeable for foreign firms, as the state contains no plants from leading foreign firms. In terms of semiconductor R&D and design, North Carolina has excelled both within the U.S. and globally. A significant portion of design and development for major global firms takes place here in RTP. In hardware, North Carolina has successfully attracted new Dell and Lenovo in the past few years, sending a message that the state is a serious player in attracting new hardware manufacturing and building a core of "magnet businesses" that can attract suppliers and customers. North Carolina's Software Industry The software industry in North Carolina has also improved recently, helped by the presence of several of the nation's leading software companies. Microsoft, SAS, and Red Hat are examples of growing companies that are leading the positive trend. Microsoft, which dominates the market for PC operating systems, and IBM, which is a key player across the industry, both have substantial operations in RTP; SAS and Red Hat are both headquartered in RTP. SAS is growing very rapidly in offering business solutions, while Red Hat is a leader in the increasingly popular open source Linux OS and is working with IBM. Many other steps that North Carolina is taking, though less direct, relate to the growth and development of the software industry. For example, one of the most important preparations North Carolina is doing impacting the software industry is in preparing its citizens to take part in the rise of computer usage in daily life. Currently, Governor Easley maintains the importance in learning and functioning with cutting-edge technology, as through his One Carolina Agenda, he proposes both the training of teachers in "21 st Century skills" and the opening of the first "21st Century skills" center to increase citizen participation in a technologically advanced society. In addition, North Carolina is seeking the help and support of top firms with greater access to resources, looking to build public-private partnerships to increase citizen use and familiarity with computers. North Carolina's IT Services Industry IT Services, though traditionally smaller than the manufacturing-based sectors, seems to be growing in North Carolina. Accenture's large office in Charlotte is a perfect example of the growth of the industry. Given the relatively young nature of this segment of the industry, it is difficult to give policy implications or future projections of where the model may lead. While corporate giants such as IBM have shown that it is profitable for large scale corporations, smaller corporations still have been struggling, due to a lack of economies of scale and name recognition these new companies cannot attain. The role of this developing industry in North Carolina remains to be seen, but should be watched with great interest over the next several years. Geography of the Industry in North Carolina The geographic distribution of IT manufacturing and software development activities is concentrated, reflecting the technological intensiveness of the industry, necessitating both the proximity of major research institutions and appropriate infrastructure. Three counties - Durham, Wake and Mecklenburg - account for most of the plants and IT industry employees, and with Guilford and Forsyth as rising locations, especially in IT services (see Maps). North Carolina Exports in the IT Industry Increasingly, North Carolina firms are also looking to export their goods abroad. Foreign demand for North Carolina exports is growing, though it remains lower than 2000 levels. Asia has solidly increased its imports from North Carolina, with China, South Korea, Japan, and Malaysia posting largest gains in recent years. Stagnating demand in some industrialized economies (the United Kingdom, Canada and the Netherlands, among others) presents cause for concern regarding future growth in exports from North Carolina (Table 4). TABLE 1 - TOP IT EMPLOYERS IN NORTH CAROLINA, 2007 Company Primary NAICS Codes2 No. of Plants, 100+ Employees1 Approx. NC Employment1 Total Sales (US$ mil.) 1 SAS Institute Inc. 5112 1 3,500 1,500 2 Verizon Communications Inc. 517 3 3,300 1,875 3 Tyco International US Inc. 334 5 2,000 785 4 Ericsson Inc. 4236 1 1,800 1,500 5 Andrew Corp. 334 1 1,400 750 6 Alcatel USA 238 1 1,400 300 7 Draka Comteq 237 1 1,200 300 8 Sprint Nextel Corp. 517 4 1,075 750 9 Heat Corporation 221 1 1,000 NA 10 Cisco Systems 5415 1 1,000 300 11 North State Communications 517 2 800 375 12 Southern Devices Div. 335 1 750 300 334, 4431 2 730 825 14 Lufkin Division 334 1 700 75 15 General Dynamics Corp. 334 3 655 185 16 Corning Cable Systems LLC 237 1 650 NA 17 Kaba-Ilco Corp. 333 1 608 NA 18 Atlantic Telephone Membership 517 3 570 450 19 AC Corp. 333 1 550 75 20 Sonopress LLC 334 1 530 NA 21 Keane Inc. 5415 2 530 110 22 AT & T Inc. (Bell South, Cingular Wireless) 517 5 510 215 23 RF Micro Svc. Inc. 334 1 500 634 13 EMC Corp. Company Primary NAICS Codes2 No. of Plants, 100+ Employees1 Approx. NC Employment1 Total Sales (US$ mil.) 24 Misys Healthcare Systems 4431 1 500 NA 25 Wilson-Cook Medical Inc. 334 1 500 NA 1. North American Industrial Classification System (NAICS) Primary NAICS Codes: 334 (Computer and Electronics Mfg.), 5112 (Software Publishing), 517 (Telecommunications), 5415 (Computer Systems Design) Other NAICS Codes: 221 (Utilities), 237 (Heavy and Civil Engineering Construction), 238 (Specialty Trade Contractors), 333 (Machinery Mfg.), 335 (Electrical Equipment Mfg.), 4236 (Eletrical and Electronic Goods Merchant Wholesalers), 4431 (Electronic and Appliance Stores) 2. Only establishments over 100 employees were tallied for this table. Source: Reference InfoUSA, 2/07 Tobacco Industry in NC INTRODUCTION AND GENERAL INDUSTRY STRUCTURE 1 The tobacco industry has traditionally been one of the most important industries in North Carolina and a backbone of the state's agricultural heritage. Yet as the North Carolina economy continues to transition from an agricultural economy to a manufacturing and, increasingly, service-based economy, the industry faces new challenges, both at home and abroad. Internationally, as barriers to free trade in agricultural products slowly fall away, new competitors have arisen to challenge the North Carolina industry. In this section, we look to describe the outline of the industry, North Carolina's footprint, important global competitors, and the key trends and dynamics that are shaping this industry now and in the future. The industry can be generally divided into two sections: Farming - This includes not only the planting, tending, and harvesting of tobacco leaf, but generally also includes initial processing steps, including curing tobacco to dry out the leaves and stems. Farmers also sort and grade tobacco, based on criteria like color and aroma Processing - This includes both initial processing of tobacco leaf (cleaning and resorting, stemming and redrying, aging) and specific manufacturing processes for a variety of final products, including cigars, cigarettes, and chewing tobacco. TOBACCO IN NORTH CAROLINA The introduction of tobacco into North Carolina has a long history. When settlers moved from Virginia to North Carolina around 1663, they struggled to grow any other crop besides tobacco in the dry, sandy soil. During this time, the Europeans viewed tobacco as a luxury and bought it from Spain. The new colonists saw the opportunity in the overseas demand for tobacco and started growing tobacco in North Carolina as a way to gain entry into the European tobacco market. 2 As centuries passed, the tobacco business became an integral part of North Carolina's culture. James B. Duke formed the American Tobacco Company in Durham and, as it expanded around the world, it continued to be based in Durham. Even today, tobacco is an instrumental part of North Carolina, especially because of its role in the employment and economy of the state. In 2005, tobacco represented 15.5% of the total value of all crops grown in North Carolina. In addition to these farmers, the tobacco business employs many 3 workers in processing, manufacturing, wholesale, and retail outlets, and related industries. Every stage of production of tobacco, from tobacco growing to final product manufacture, is located in North Carolina, and this state has been one of the centers of the US tobacco industry. North Carolina ranks first in the United States in the production of tobacco, with 2006 annual farm income of $506.2 million. Tobacco is 4 a crop that can be grown in a wide range of soil and climate conditions, and 16 states and approximately 120 countries produce it across the world. Geographical differences exist in the production of the two main 5 types of tobacco produced in this state: air- and flue-cured tobacco. Air-cured tobacco differs from fluecured tobacco in a number of ways, including the filling power and pH of the smoke. North Carolina's soil is, in general, more adept at growing flue-cured tobacco, and, thus, smaller amounts of air-cured tobacco are produced in North Carolina. Many prominent companies in the tobacco industry are linked in some way to North Carolina. Phillip Morris, the country's largest cigarette company, is one example. Phillip Morris held 50.4% of the cigarette market in the first quarter of 2007. While Phillip Morris' headquarters is located in Virginia, they maintain a 6 manufacturing facility in Cabarrus County. Other well-known companies are entirely based in North Carolina. Reynolds American Inc. is another tobacco giant that recently formed when R.J. Reynolds Tobacco Co. joined with the Brown & Williamson Tobacco Corp. in 2004. R.J. Reynolds is the second-largest tobacco company in the country and is centered in Winston-Salem, North Carolina. R.J. Reynolds produced nearly one out of every four cigarettes sold in the United States, and they own four of the nation's ten best -selling brands (Camel, Winston, Salem, Doral). Finally, the Lorillard Tobacco Co., the third largest U.S. tobacco firm, is centered in Greensboro, NC. 7 As centuries passed, the tobacco business became an integral part of North Carolina's culture. James B. Duke formed the American Tobacco Company in Durham and, as it expanded around the world, it continued to be based in Durham. Even today, tobacco is an instrumental part of North Carolina, especially because of its role in the employment and economy of the state. Tobacco represents 14% of the total cash crop value in North Carolina. In addition to these farmers, the tobacco business employs many workers in processing, 4 manufacturing, wholesale, and retail outlets, and related industries. RECENT INDUSTRY TRENDS AND DEVELOPMENTS Until 2004, the tobacco industry operated within a system of quotas in place since 1938. Recently, quotas have become concentrated within relatively fewer hands. In the past couple of decades, demand for cigarettes has declined while foreign competition in tobacco production has increased, thus threatening the livelihood of U.S. tobacco farmers. As a result, the U.S. government has decided to limit quotas and price supports in recent years. In addition, these changes affect other areas of the industry, most notably the 8 cigarette producers. In October 2004, Congress legislated the end of tobacco quotas in exchange for a one-time buyout. This will affect North Carolina substantially. One-third of the buyout money is going to 10% of the owners, some being paid over $7 million due to the size of their quota holdings. Most experts predict that these huge farms will prosper after the buyout because of their size. However, smaller farms will most likely start to disappear. 9 Many farmers are responding to these and other competitive challenges by diversifying some of their crop production. In 1997, 95% of farmers interviewed responded that they had grown or raised a commodity other than tobacco within the past year. The commodities included a variety of livestock, grains, fruits, and vegetables. Only a small percentage of these farmers, however, reported a profit from these enterprises. This is, in part, due to the high profitability per acre that tobacco provides. There were internal and external 10 barriers to diversification, including rates of personal tobacco use, high relative income from tobacco, lack of college education of many farmers, and the size of their farms. As imports continue to climb and smoking rates in the general population fall, farmers should prepare themselves for declining demand by diversifying their crops. By finding the commodities that are a good fit for their fields as well as profitable on the market, this could prepare them for the future decline of tobacco. TABLE 1 - TOP TOBACCO EMPLOYERS IN NORTH CAROLINA, 2007 Company Primary NAICS Codes1 No. of Plants NC Employment Total Sales (US$ mil.) 1 Loews Corp. (Lorillard Tobacco Co.) 312221, 312229 5 2,663 1,511 2 Altria Group (Philip Morris USA) 312229 1 2,500 1,500 3 Alliance One Int'l. Inc. (CRES Tobacco Co., Inc,) 31221, 312229, 42459, 42491 5 1,085 750 4 Export Leaf Tobacco Co. 31221 1 1,000 750 5 Reynolds American Inc. 312221, 312229 11 763 519 6 Vector Group LTD 312221, 312229 2 420 401 7 Commonwealth Brands Inc. 312221 1 230 750 8 Top Tobacco LP 312229 1 104 35 9 Alternative Brands Inc. 312221 1 75 300 11191 1 60 2 10 Kelly Farms 1. North American Industrial Classification System (NAICS) Primary NAICS Codes: 11191 (Tobacco Farming), 31221 (Tobacco Stemming and Redrying), 312221 (Cigarette Mfg.), 312229 (Other Tobacco Product Mfg.) Other NAICS Codes: 42459 (Other Farm Product Raw material Merchant Wholesalers), 42491 (Farm Supplies Merchant Wholesalers) Source: Reference InfoUSA, 2/07