Insert Your Title

advertisement

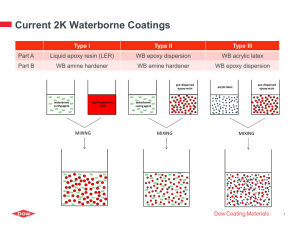

Industrial Strength: Benefits of Waterborne Acrylic Coatings Mary Rose Correa and Leo Procopio December 15, 2015 Dow.com Agenda Market Perspective • Market background • Trend analysis Waterborne Acrylics 101: The Basics • • • • What is an acrylic? Benefits & Challenges of WB Film formation Performance & Recent Advances in the State-of-the-Art Industrial Applications with Waterborne Solutions • Examples of where WB Acrylics are used in Industrial applications 2 Market Perspective 3 Perspective: Why are we talking about WB? U.S. Coatings Market U.S. Coatings Market (Gallons Consumed) U.S. Coatings Market by Technology 4% WB 5% 24% 53% 2%1% SB Special Purpose 23% Powder OEM 33% Architectural 55% 100% Solid E-coat Radcure 2011 Consumption WB by Segment • 1.4 Billion gallons • Architectural – 72% • Valuation of $23.1 Billion • Special Purpose – 18% • OEM – 10% • 60% of value is from Industrial segments Source: The US Paint & Coatings Industry 2011-2016; Kusumgar, Nerfli & Growney, 2012 4 Why the drive towards waterborne coatings? • Regulations and specifications around the globe • Volatile Organic Compounds (VOCs) • EPA, SCAQMD (California), OTC, CARB, etc. • Hazardous Air Pollutants (HAPs) • EPA • Interior air quality • LEED, Greenguard, BIFMA, etc. • End-user demands for greener / more sustainable products • Demand for coatings with lower odor, lower flammability 5 Benefits & Challenges of Waterborne Coatings Benefits Low VOC = less impact on environment Low odor Less concern over worker exposure to hazardous solvents Better “cycle time” for various trades Lower or no risk of fire from handling flammable solvents Easy and safer cleanup Challenges • Application window, i.e., length of painting season • Drying rate dependent on humidity • Reduced water resistance • Surfactants • Salts • Often reduced substrate wetting • Higher surface tension of water Less waste and hazardous disposal • Open time Ease of use • Film formation Proven performance in real world applications • Perceived lower performance vs SB coatings 6 Primary Types of Waterborne Coatings Acrylic and Vinyl-acrylic Latex Epoxy Dispersions Polyurethane Dispersions (PUD’s) 2K Polyurethanes Water Reducible Alkyds & Alkyd Dispersions Zinc Rich • Inorganic Silicate • Organic (Epoxy) 7 Waterborne Acrylics in Industrial Coatings Field-applied industrial maintenance coatings for metal and concrete Traffic and roadmarking paints Elastomeric roof coatings General industrial finishing Plastic coatings Concrete and metal roof tiles Fiber cement siding Wood and wood composite coatings: e.g., cabinets, furniture, joinery Coil coatings 8 Industrial Maintenance Applications Using WB Acrylics Storage tanks Bridges Shipping containers Railcars Structural steelwork Commercial Architectural Metal buildings Water towers Pipes 9 Industrial Maintenance Coatings Market: Technology Distribution Segmentation of U.S. Industrial Maintenance Coatings Market by Technology: Volume of Coatings (2010) WB Alkyd 2% Other 13% SB Alkyd 10% WB Acrylic 24% SB and 100% solids Epoxy 32% Industrial Maintenance Coatings market in the US was estimated at 52 MM gallons and $817 MM for 2010 SB Polyurethane 14% WB Epoxy 3% SB Acrylic 1% WB Polyurethane 1% Source: US Paint & Coatings Industry Market Analysis (2010-2015), American Coatings Association, 2012 10 Key Trends and Drivers in Industrial Space Sustainability/Regulations • Trend toward WB, high solids • VOC/odor reduction • Carbon footprint • Human health & safety Performance • Surface compatibility • Improved durability/resistance • Extreme environment corrosion protection Cost Effectiveness • Reduced prep, application time/number of coats • Extended pot life • Optimized processing 11 Waterborne Acrylics 101: The Basics 12 Acrylic Polymer Technology • Acrylics are based on esters of acrylic and methacrylic acid, but can also include other non-acrylic monomers such as styrene and vinyl acetate • Solventborne and waterborne acrylic polymers are available • First uses date to the late 1920’s, when acrylic polymers were used in making automobile safety glass Acrylates R = Et, Bu, etc. Methacrylates R = Me, Bu, etc. Styrene Vinyl Acetate 13 Acrylic Polymer Formation Vinyl group • Acrylics are typically made via free radical polymerization of the unsaturated vinyl group • Process can occur in solvent or water • Results in a high molecular weight polymer 14 Variety of Acrylic Monomers are Available • A wide range of acrylic monomers are available • They vary in hydrophobicity, Tg (hardness), functionality for adhesion or reactivity, etc. • Acrylic polymers can be tailored for a wide range of properties R" H Me Et n-Bu i-Bu 2-ethylhexyl Acrylates (R' = H) Name acrylic acid methyl acrylate ethyl acrylate butyl acrylate isobutyl acrylate 2-ethylhexyl acrylate Metha Tg (°C) 110 8 -22 -54 -53 -65 N metha methyl m ethyl m butyl m isobutyl 15 Uses of Acrylic Polymer Technology • Paints and coatings • Motor oil additives • Adhesives • Leather tanning and finishing • Caulks and sealants • Plastic, e.g., Plexiglas • Scale inhibitors for water systems • Personal care products • Detergent additives • Cement modifiers • Textile finishes • Floor polishes Global production of monomers: Acrylic acid • 5 million metric ton • 75% for super-absorbant Acrylate esters • 4.3 million metric tons • 36% into coatings Methyl methacrylate • 3 million metric tons • (20% into coatings) • Paper coatings 16 Brief History of Acrylic Coatings 1930’s Solventborne acrylics first used in coatings 1940’s Solvent-based oil and alkyd paints dominate the architectural market 1948 First waterborne latex paint based on SBR 1950’s Commercial use of SB acrylics grew significantly 1955-1971 SB thermoplastic acrylics used on all U.S. made GM automobiles 1953 First WB acrylic latex introduced for interior architectural coatings and masonry 1961 First WB acrylic specifically for exterior architectural coatings 1970’s WB acrylics with good adhesion to chalky substrates, stain-blocking primers 1980’s Improved WB acrylics for metal and masonry substrates, first hollow sphere pigments, high gloss trim paints, multi-lobe technology 17 Brief History of Acrylic Coatings 1990’s Acrylics capable of interior/exterior performance, self-crosslinking acrylics, low solvent binders, improved hollow sphere pigments, improved corrosion resistance Today WB acrylics dominate the architectural market, and are heavily utilized in industrial painting. Trends are to lower VOC and higher performance. Acrylic Coatings Market Size: By volume, acrylics are the leading technology used in coatings • ~25% of all coatings volume globally • 6 million metric tons of finished coatings • $20 billion value 18 Why Use Acrylics in Paints and Coatings? • Excellent resistance to ultraviolet light (UV), which translates into excellent exterior durability • Color and gloss retention • Maintain clarity • Resistance to chalking • Toughness • Maintain flexibility and resistance to embrittlement • Resistant to grain cracking over wood • Hydrolytically stable • Wide range of compositions attainable (i.e., can tailor composition for various applications) 19 What are Waterborne Acrylic Coatings? • Paints and coatings based on WB acrylic polymers and co-polymers (i.e., acrylic latex or acrylic emulsion polymers) • Vinyl-acrylics are common copolymers of acrylic monomers with vinyl acetate • Most commonly associated with architectural coatings, but are used in numerous industrial paints and coatings Two Types of Coatings Systems One-component • Thermoplastic acrylics • Self-crosslinking thermoplastic acrylics • Elastomeric acrylics Two-component • Acrylic / epoxy • Acrylic polyurethane 20 Types of Waterborne Polymers Carrier: Mol. Wt. Latex Dispersion Water-reducible Water High Water Low-Med Solvent Low 21 What is an acrylic latex polymer? • Synthesized by emulsion polymerization of acrylic monomers • Results in a dispersion of discrete, colloidal particles in water • Each particle contains many high MW polymer chains Appearance: Like milk, translucent to opaque white, but dries to a clear film Particle size: 50 – 500 nanometers, usually spherical Solids: 30 – 65% by weight 22 How do WB polymers differ from SB polymers? Type Latex polymer Solution polymer Carrier Water Various solvents MW High (up to 1 million) Low (5 - 100K) Viscosity Dependent on particle size Dependent on MW 23 Film formation process • Film formation: Conversion of a coating film from a liquid or fluid form into a solid. Entanglement of polymer chains gives the film cohesion and strength. • The film formation process is one of the main differences between WB coatings and SB coatings • It is key to understanding performance of WB coatings and some of the reasons for failures 24 Film formation process • The goal of film formation is to form a “good” film • What is a “good” film? • Defined by the end use of the film or coating: • • • • • • • Block resistance Tensile strength Elongation Barrier properties Stain resistance Corrosion resistance Water resistance 25 Film formation for solvent borne coatings Solvent evaporation and polymer entanglement Crosslinking Examples of crosslinking would be reactions via oxidation (e.g., alkyds) or via crosslinkers (e.g., 2K epoxies and polyurethanes 26 Film formation for latex coatings Stage 1: Coating applied to substrate Stage 2: Close packed array w/ water-filled interstices Stage 3: Compacted array of deformed particles Stage 4: Loss of particle boundaries Homogeneous film Water evaporation and latex particle packing Water diffusion and particle deformation Polymer chain interdiffusion 27 Factors affecting latex film formation Latex polymer variables • Tg - Glass transition temperature • Molecular weight • Particle size Formulation • Coalescents & Plasticizers • Pigment Drying Environment • • • • Temperature Humidity Air Velocity Substrate Porosity 28 Conditions leading to poor film formation If latex particles don’t coalesce properly, microscopic voids and channels will be present, and lead to poor barrier properties. In worst case, this leads to cracked and friable film. Humidity: • Too high application humidity can cause coalescents to leave before water. When water finally evaporates, there is not enough coalescent to allow latex particles to deform. • Air movement helps alleviate this potential problem. • Manufacturers usually recommend a maximum humidity of 85 – 90%. 29 Conditions leading to poor film formation Temperature: • Latex polymers are often formulated with coalescent to form a film within a certain temperature range • Recommended range is usually between 45 – 110°F • Too low application T or formulation with too little coalescent/plasticizer leads to incomplete coalescence • Too high application T leads to water and coalescent flashing off before particles coalesce 30 The Importance of Film Formation: Effect of Coalescent Level on Corrosion Resistance 200 hr salt spray (ASTM B117) on blasted hot rolled steel 18 PVC Gloss white acrylic latex DTM formula Coalescent level: 5% 10% 15% 20% 31 Important factors for success Coating -Choice of coating type -Quality formulation -Performance (e.g., adhesion) -Surface wetting -No defects Application -Environmental conditions -Prevent defects (e.g., foam) -Proper film thickness Surface Prep -Anchor profile -Cleanliness -Remove contaminants 32 Industrial Applications with Waterborne Solutions 33 Types of Waterborne Acrylic Coatings Available Waterborne acrylic resins are used in the following types of industrial maintenance and commercial architectural coatings: Primers • Wash primers • Anti-corrosive primers • Block fillers • Masonry primers Direct-to-substrate finishes • DTM finishes • Elastomeric wall & roof coatings Topcoats • Gloss to flat sheens • Clear or pigmented Functional coatings • Thermal insulation • Sound Damping • Formaldehyde abatement 34 Service Environments for Waterborne Acrylics Waterborne acrylic coatings, particularly the 1K variety, are usually used in service environments defined as low to medium duty: • ISO 12944 corrosion categories: e.g., C1 - C3 • SSPC Environmental Zones: e.g., • 1A (interior, normally dry) • 1B (exterior, normally dry) • 2A (Frequently wet by fresh water) 35 Industrial Uses of WB Acrylics: Bridge Coatings Where Used? • Steel and concrete bridges – primers and topcoats • Often used over primers of other chemistry, e.g., Zn rich • Specified and used by states such as CA, GA, NC, FL, etc. Key Attributes • Low VOC • Color and Gloss retention • 1K ease of use • Barrier properties – corrosion resistance 36 Industrial Uses of WB Acrylics: Rail & Container Where Used? • Boxcars, hopper cars, gondola cars – exterior DTMs • Shipping containers – primers/topcoats Key Attributes • Low VOC • Fast dry • Gloss • Color and Gloss retention • 1K ease of use • Barrier properties – corrosion resistance 37 Recent Advances in WB Acrylic Protective Coatings: DTM Coatings with lower VOC and less corrosion The challenge for WB Acrylic DTM coatings has been to improve barrier properties (i.e., corrosion resistance) while also lowering VOC Solution • Improve pigment distribution in dry coating by enhancing the latex-pigment interaction in the wet paint via formation of latex-pigment composites • Optimize morphology of latex particles to give good film formation with minimal impact on hardness Result • WB Acrylic DTMs with excellent corrosion resistance and VOC < 50 g/L 38 Film Formation with Latex-Pigment Composites • • Optimizing pigment dispersion through formation of latex-pigment Composite Particles in the wet state Composite particle formation 39 Block Resistance Hardness properties such as block resistance can be difficult to maintain when lowering VOC levels. 1 Day Block Resistance 8 7 6 5 4 3 2 1 0 Low VOC DTM Commercial #1 <200 VOC 1 Day, 30 min. Oven Block Commercial #2 <50 VOC Commercial #3 <100 VOC 1 Day, Room Temp. Block 40 Corrosion Resistance 1000 Hours Salt Spray Exposure over Cold Rolled Steel New technology 8% coalescent < 50 g/L Commercial DTM #1 <200 VOC Stopped @ 576 hours Commercial DTM #2 <50 VOC Stopped @ 576 hours Commercial DTM #3 <100 VOC 41 Industrial Uses of WB Acrylics: Commercial Architecture Where Used? • Interior and exterior walls – concrete, drywall • DTMs for steel structures • Roof coatings • Interior floor coatings Key Attributes • Low VOC, low odor • Color and Gloss retention • 1K ease of use • Barrier properties – corrosion and water resistance • Chemical / solvent resistance • Abrasion resistance 42 Recent Advances in WB Acrylic Commercial Coatings: Wall Coatings to Improve Indoor Air Quality • Indoor Air Quality is a topic of increased interest for both residential and commercial buildings • Increased awareness by builders and architects in considering the comfort, health and wellness of building occupants • Wall coatings represent a large surface area within a building – can a functional coating be used to improve the indoor air quality? • The new technology is for wall coatings and based on a WB acrylic polymer with functionality that reacts with formaldehyde and irreversibly removes it from the air 43 Mechanism: How can a coating affect indoor air quality? 1. Formaldehyde make contact with formaldehyde abatement functionality 2. Reaction permanently removes formaldehyde 3. Transforms indoor air pollutant into harmless vapor 44 Conclusions • Waterborne acrylics are one of the major technologies used in Industrial and Commercial Coatings • Wide range of compositions and performance is available for the varying application requirements • Understanding the film formation mechanism of latex coatings is a key to the successful use and ultimate performance of WB Acrylics • New advances are pushing the limits on performance, such as: • Corrosion resistance • Low VOC capability • Added functionality, such as formaldehyde abatement • WB Acrylics are being used successfully in many industrial applications, and offer a safer and more sustainable alternative to traditional solventborne coatings. 45 Q&A FOR A COPY OF THE PRESENTATION, PLEASE CONTACT: CoatingMaterials@dow.com 46 Disclaimer HANDLING PRECAUTIONS PRODUCT STEWARDSHIP CUSTOMER NOTICE Before using any product mentioned herein, consult the product’s Material Safety Data Sheet (MSDS)/Safety Data Sheet (SDS) for details on product hazards, recommended handling precautions and product storage. Dow has a fundamental concern for all who make, distribute, and use its products, and for the environment in which we live. This concern is the basis for our product stewardship philosophy by which we assess the safety, health, and environmental information on our products and then take appropriate steps to protect employee and public health and our environment. The success of our product stewardship program rests with each and every individual involved with Dow products - from the initial concept and research, to manufacture, use, sale, disposal, and recycle of each product. Dow strongly encourages its customers to review both their manufacturing processes and their applications of Dow products from the standpoint of human health and environmental quality to ensure that Dow products are not used in ways for which they are not intended or tested. Dow personnel are available to answer your questions and to provide reasonable technical support. Dow product literature, including safety data sheets, should be consulted prior to use of Dow products. Current safety data sheets are available from Dow. NOTICE: No freedom from infringement of any patent owned by Dow or others is to be inferred. Because use conditions and applicable laws may differ from one location to another and may change with time, Customer is responsible for determining whether products and the information in this document are appropriate for Customer's use and for ensuring that Customer's workplace and disposal practices are in compliance with applicable laws and other government enactments. The product shown in this literature may not be available for sale and/or available in all geographies where Dow is represented. The claims made may not have been approved for use in all countries. Dow assumes no obligation or liability for the information in this document. References to “Dow” or the “Company” mean the Dow legal entity selling the products to Customer unless otherwise expressly noted. NO WARRANTIES ARE GIVEN; ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED. NOTICE: If products are described as "experimental" or "developmental": (1) product specifications may not be fully determined; (2) analysis of hazards and caution in handling and use are required; (3) there is greater potential for Dow to change specifications and/or discontinue production; and (4) although Dow may from time to time provide samples of such products, Dow is not obligated to supply or otherwise commercialize such products for any use or application whatsoever. 47 Thank You For additional information, please contact coatingmaterials@dow.com ®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow 48