INDUSTRIAN HYGINE MONITORING AT JB COCOA SDN BHD

advertisement

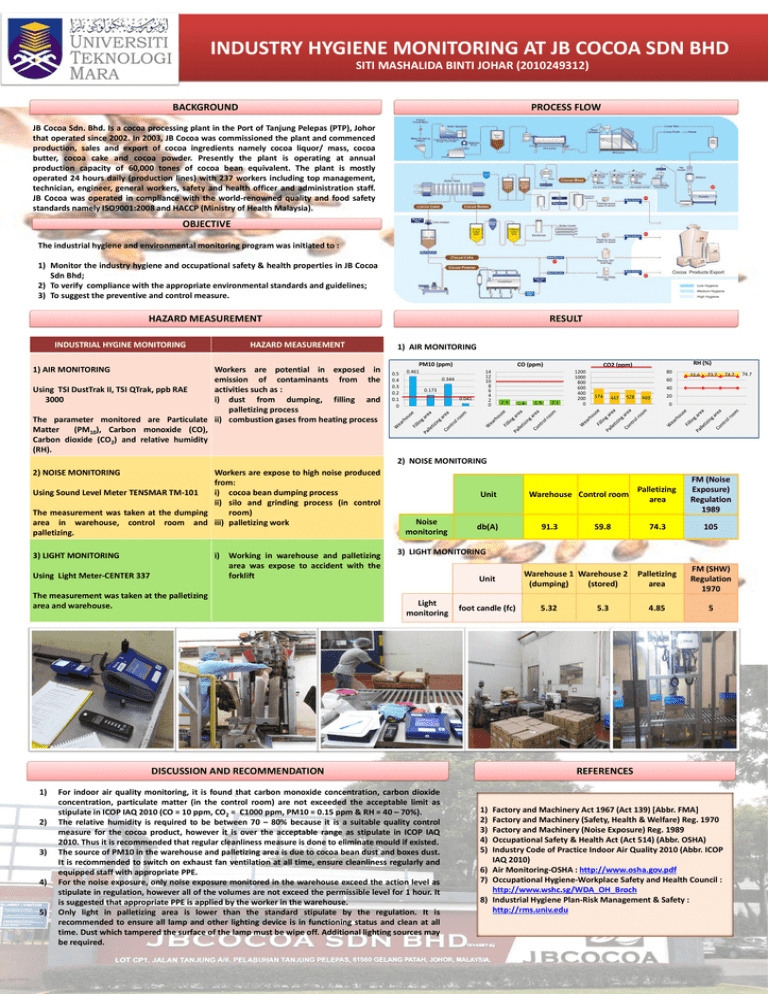

INDUSTRY HYGIENE MONITORING AT JB COCOA SDN BHD SITI MASHALIDA BINTI JOHAR (2010249312) BACKGROUND PROCESS FLOW JB Cocoa Sdn. Bhd. Is a cocoa processing plant in the Port of Tanjung Pelepas (PTP), Johor that operated since 2002. In 2003, JB Cocoa was commissioned the plant and commenced production, sales and export of cocoa ingredients namely cocoa liquor/ mass, cocoa butter, cocoa cake and cocoa powder. Presently the plant is operating at annual production capacity of 60,000 tones of cocoa bean equivalent. The plant is mostly operated 24 hours daily (production lines) with 237 workers including top management, technician, engineer, general workers, safety and health officer and administration staff. JB Cocoa was operated in compliance with the world-renowned quality and food safety standards namely ISO9001:2008 and HACCP (Ministry of Health Malaysia). OBJECTIVE The industrial hygiene and environmental monitoring program was initiated to : 1) Monitor the industry hygiene and occupational safety & health properties in JB Cocoa Sdn Bhd; 2) To verify compliance with the appropriate environmental standards and guidelines; 3) To suggest the preventive and control measure. HAZARD MEASUREMENT INDUSTRIAL HYGINE MONITORING HAZARD MEASUREMENT 1) AIR MONITORING Workers are potential in exposed in emission of contaminants from the Using TSI DustTrak II, TSI QTrak, ppb RAE activities such as : 3000 i) dust from dumping, filling and palletizing process The parameter monitored are Particulate ii) combustion gases from heating process Matter (PM10), Carbon monoxide (CO), Carbon dioxide (CO2) and relative humidity (RH). RESULT 1) AIR MONITORING PM10 (ppm) 0.5 0.4 0.3 0.2 0.1 0 CO (ppm) 0.461 0.344 0.173 0.041 14 12 10 8 6 4 2 0 2.4 1.6 1.9 RH (%) CO2 (ppm) 2.1 1200 1000 800 600 400 200 0 80 60 72.6 73.7 74.2 40 574 447 528 469 20 0 2) NOISE MONITORING 2) NOISE MONITORING Workers are expose to high noise produced from: Using Sound Level Meter TENSMAR TM-101 i) cocoa bean dumping process ii) silo and grinding process (in control The measurement was taken at the dumping room) area in warehouse, control room and iii) palletizing work palletizing. 3) LIGHT MONITORING i) Using Light Meter-CENTER 337 Working in warehouse and palletizing area was expose to accident with the forklift The measurement was taken at the palletizing area and warehouse. Unit Noise monitoring db(A) 2) 3) 4) 5) 91.3 59.8 Palletizing area 74.3 105 Palletizing area FM (SHW) Regulation 1970 4.85 5 3) LIGHT MONITORING Unit Light monitoring foot candle (fc) DISCUSSION AND RECOMMENDATION 1) Warehouse Control room FM (Noise Exposure) Regulation 1989 For indoor air quality monitoring, it is found that carbon monoxide concentration, carbon dioxide concentration, particulate matter (in the control room) are not exceeded the acceptable limit as stipulate in ICOP IAQ 2010 (CO = 10 ppm, CO2 = C1000 ppm, PM10 = 0.15 ppm & RH = 40 – 70%). The relative humidity is required to be between 70 – 80% because it is a suitable quality control measure for the cocoa product, however it is over the acceptable range as stipulate in ICOP IAQ 2010. Thus it is recommended that regular cleanliness measure is done to eliminate mould if existed. The source of PM10 in the warehouse and palletizing area is due to cocoa bean dust and boxes dust. It is recommended to switch on exhaust fan ventilation at all time, ensure cleanliness regularly and equipped staff with appropriate PPE. For the noise exposure, only noise exposure monitored in the warehouse exceed the action level as stipulate in regulation, however all of the volumes are not exceed the permissible level for 1 hour. It is suggested that appropriate PPE is applied by the worker in the warehouse. Only light in palletizing area is lower than the standard stipulate by the regulation. It is recommended to ensure all lamp and other lighting device is in functioning status and clean at all time. Dust which tampered the surface of the lamp must be wipe off. Additional lighting sources may be required. Warehouse 1 Warehouse 2 (dumping) (stored) 5.32 5.3 REFERENCES 1) 2) 3) 4) 5) Factory and Machinery Act 1967 (Act 139) [Abbr. FMA] Factory and Machinery (Safety, Health & Welfare) Reg. 1970 Factory and Machinery (Noise Exposure) Reg. 1989 Occupational Safety & Health Act (Act 514) (Abbr. OSHA) Industry Code of Practice Indoor Air Quality 2010 (Abbr. ICOP IAQ 2010) 6) Air Monitoring-OSHA : http://www.osha.gov.pdf 7) Occupational Hygiene-Workplace Safety and Health Council : http://www.wshc.sg/WDA_OH_Broch 8) Industrial Hygiene Plan-Risk Management & Safety : http://rms.univ.edu 74.7