Evaluation

advertisement

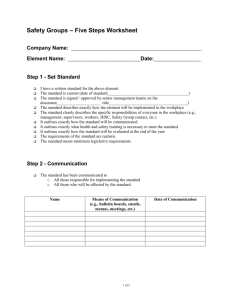

STEP 4 – EVALUATION “Are we doing what we said we would do?” 5-Steps to Managing Health & Safety Acknowledge Success & Make Improvements 1 5 Written Standard Evaluate 2 4 Communication 3 Training Evaluation - What does this mean? 1. Verifying that the company’s standards are still current and up-to-date to both: – Legislation and – Company business practices 2. Verifying that what is actually being done in the workplace meets the standards and company rules established in Setting Standards (Step 1). “Is the workplace doing what it said that it would do?” WHY DO EVALUATION? Benefits of Evaluation • Assess implementation of your element • Assess what’s working & what’s not working –Identify “gaps” in your health & safety program • Address workplace culture issues i.e. employee participation, supervisor support, functional JHSC • Record review opportunity re: standards, communication & training • Review accident/incident/near miss • Recommend improvements to H&S Program Evidence of Evaluation 1. ASK 2. REVIEW / ANALYZE 3. REPORT • Collection of Data – Consider What/Why, How, When, & Who – i.e. Administer a Quiz to 50 staff. • Review or Analyze the data collected – Consider Who, When & How? – i.e. Score the quiz & tabulate the overall results and identified gaps. • Reporting the Results = EVALUATION – Consider to Who, When, How & Where? – i.e. Quiz results are discussed at JHSC and minutes posted. Negative Results • The results of the Evaluation indicates “Negative Results” – For this element, “the company is not doing what the Standard expects it to do” • Is this still Evaluation (Step 4)? YES! • Negative results (or less than positive results) provide for “Opportunities for Improvement”. • This is the importance of EVALUATION. Best Practices • Write method of evaluation in Standard ( who, what, how, where & when) – Include benchmarks in your written standards. – Set a schedule • Use or Add-to existing methods for Evaluation: – Include on JHSC agenda to review elements - Recommend actions; Record in JHSC minutes & Post; – Review elements at Management Meetings - Address recommendations; Action plan to improve & Minute meetings; – Use monthly Workplace Inspections - Complete checklist; Action items; Action taken; post results. – Regular worker observations - Set schedule; Ask supervisors to keep log books/checklists; include in inspection; internal audit. Program Requirements for Evaluation (Step 4) • Document all forms of evaluation – incorporate into existing methods • Aim to complete Evaluation by year- end. – If not, must complete by March of following year (prior to spot checks starting). • But - MUST have written plan of “how” element will be evaluated and completed by March to put “Y” on Yearend Report Acknowledging Success & Making Improvements Based on the results of your evaluation: – Recognize everyone who contributed to a successful health & safety program by meeting & surpassing company standards, for example: • • • • Letter/memo from the president Newsletter Health & Safety awards or certificates Public recognition (i.e. coffee & muffins for JOHSC and/or employees) • Performance Evaluations – Accept negative evaluation results as opportunities for improvement - develop an action plan Step 4 - Evaluation 10 Best Practices/Examples/Samples 1. Interview/survey employees 2. Quiz 3. Scheduled workplace/site/shop inspections or tours 4. Joint Health & Safety Committee 5. Management Team Review 6. Internal audit 7. Observations 8. Checklists 9. Injury/incident statistical analysis 10.Third party review/audit Group Workshop 1. In your group, discuss and plan how to EVALUATE the element provided. 2. Discuss how you will show EVIDENCE / DOCUMENTATION of the evaluation? (Remember: “ASK – REVIEW – REPORT”) 3. Discuss how you will acknowledge success or make improvements based on your evaluations. 4. A rep from your table will be asked to share the evaluation plan with the group, and /or identify any group challenges. Interview/Survey Employees 1. 2. 3. 4. Determine your objectives Address all elements simultaneously Identify required amount of participation Develop list of questions relating to elements and your objectives 5. Questions can either be asked verbally one-on-one with staff or by handouts SAMPLE Interview/Survey Employees Do you know where the JHSC Yes Where:_______________________________ Don’t know Who do you notify if you need first aid treatment? Yes Who____________________ Don’t know You suffer work place injury and will be absent from Work. List Responsibilities? ________________________ _________________________________________________ _________________________________________________ Employee Quiz Determine your objectives Address all elements simultaneously Determine participation level 100% (mandatory or voluntary) Develop questions specific to objectives and elements Questions?? quiz format, multiple choice, true/ false, fill in the blanks, etc. SAMPLE: Quiz Examples Is PPE checked regularly for wear or defects, and replaced immediately if necessary? Yes No Don’t know The hazard reporting procedures allows for immediate reporting and corrective action without waiting for the next round of regular inspections. Yes No Don’t know Is the Health & Safety Representative selected by the owner? Yes No Don’t know Scheduled Workplace/Site/Shop Inspections or Tour • include all 5 elements in monthly inspection report/checklist • ensure JHSC/representative or supervisor understands • Ask questions of workers • Have JHSC review results and make recommendations • Ensure recommendations are recorded in JHSC minutes Joint Health & Safety Committee • JHSC must be an active participant in the safety group initiatives since the start of year • Discuss at meetings/record in minutes • Provide JHSC all pertinent information: meeting minutes, inspection reports, injury statistics, supervisor’s comments, training records, etc • Discussion to identify areas of improvement for next year and areas of success Management Review • Management & supervisors must be aware and involved in safety group initiatives during the year • Hold meetings ( quarterly updates) • Present to management team the progress of the 5 elements and necessary documentation • Discussion • Areas of improvement • Areas of success • Next years elements Internal Audit • Measure organization against external standards – Workwell Core Audit or corporate audit, CSA, other guidelines • Use entire audit or use portions of audit that apply to your element selection Internal Audit Sample Guidelines from Workwell Core Audit: • Early & Safe Return to Work – Roles & responsibilities – Contact with injured worker – Medical monitoring and treatment – Provisions for modified work – Re-integration of the worker to regular work – Reporting requirements to WSIB • Action Required with Target Dates – policy required: including roles & responsibilities Observations • Decide who and what will be observed • Physically observe activity being done – lock-out/tag-out, Fork truck, Emergency Evacuation, Confined Space • Conducted by supervisor and/or JHSC • Provide immediate feedback to employee • Can be used in conjunction with annual performance reviews SAMPLE Observation Example Forklift Procedures Date:___________ Observers’ Name: _________________ Operator: __________________________ Pre-Operation Check General Operation: operating around personnel, reversing, parking load handling: pick-up, placement, stacking, re-stocking loading /unloading operational maintenance: refueling Immediate Feedback: Operator Comments: Recommendations: Checklist Format • Identify in advance how and what will be evaluated • Excellent resource document for year-end documentation Checklist • See SAMPLE Appendix C- Evaluation Form Safety Group Evaluation Form Initial Year or Maintenance Element Safety Element : ____________________________________________________________________ Instructions: 1. Reviewers are to familiarize themselves with the Standard set in the Working Instructions and determine that it is current, relevant and meets legislative requirements. 2. Reviewers are to conduct an evaluation to see that Standard is known and practiced in the shop. 3. Reviewers will observe practices, or interview sample employees to see that details in the element are known, employees understand the training that they were given, and that the work is being done according to the standard for the element. 4. Evaluate using at least one of the following: RTW Self-Assessment Guide RTW Self-Assessment Guide http://www.wsib.on.ca/wsib/wsibsite.nsf/LookupFiles/D ownloadableFileRTWSelf_AssessmentGuide/$File/RT WSelfAssessment.pdf Injury/Incident Statistical Analysis • Opportunity to measure the impact of completed elements on the injury/incident rates in the workplace • Consider using: – a historical comparison against previous years – a comparison by locations or branches within business – a comparison to your rate group SAMPLE Injury/Incident Statistical Analysis 90 • Analyze key indicators in your 80 workplace: 70 – Lost-time injuries 60 – No lost-time injuries – First Aid 50 – Near misses 40 – Property Damage 30 – Duration of WSIB claims 20 10 0 2003 LTI's 2004 LTI's 2005 LTIS 1st Qtr 3rd Qtr Third Party • Corporate auditor, health & safety association, safety group member, health & safety professional ( ergo, hygienist) Benefits • Address all elements at same time • Auditor will provide insight and recommend improvements