Construction Site Safety

advertisement

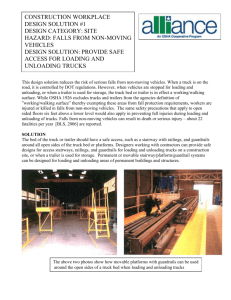

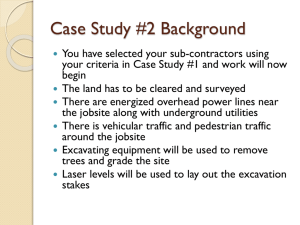

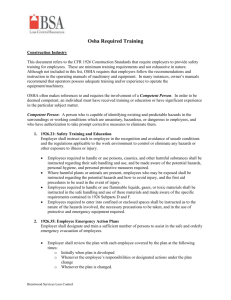

Construction Site Safety Presented by: John Able, CSP Occupational Safety Training Specialist CONN-OSHA March 17, 2015 Objectives Fall Protection Scaffolding, Stairs and Ladders Electrical Hazards Trenching Safety 1926.20 General Safety and Health Provisions 1926.20(b) Accident prevention responsibilities – It shall be the responsibility of the employer to initiate and maintain such programs as may be necessary to comply with this part. – Such programs shall provide for frequent and regular inspections of the job sites, materials and equipment to be made by competent persons designated by the employers. 1926.21 Safety Training and Education 1926.21(b) Employer responsibility – The employer shall instruct each employee in the recognition and the avoidance of unsafe conditions and the regulations applicable to his work environment to control or eliminate any hazards or other exposure to illness or injury. 1926 Subpart M - Fall Protection 1926.500 (b) Definitions applicable to this subpart (continued) "Personal fall arrest system" means a system used to arrest an employee in a fall from a working level. It consists of an anchorage, connectors, a body belt or body harness and may include a lanyard, deceleration device, lifeline, or suitable combinations of these. "Positioning device system" means a body belt or body harness system rigged to allow an employee to be supported on an elevated vertical surface, such as a wall, and work with both hands free while leaning. 1926.501(b)(1) "Unprotected sides and edges" Trigger height - 6 feet or more Your choice(s)… Personal fall arrest system (PSAF) Guard rails Safety net Each employee on walking/working surfaces shall be protected from falling through holes above lower levels, by personal fall arrest systems, covers, or guardrail systems erected around such holes. 1926.502(b) "Guardrail systems" Top edge height of top rails shall be 42 inches plus or minus 3 inches capable of withstanding, without failure, a force of at least 200 pounds 1926.502(d) Personal fall arrest system (PFAS) Horizontal lifelines shall be designed, installed, and used, under the supervision of a qualified person, as part of a complete personal fall arrest system, which maintains a safety factor of at least two. Lanyards and vertical lifelines shall have a minimum breaking strength of 5,000 pounds. Anchorage's used for attachment of personal fall arrest equipment be capable of supporting at least 5,000 pounds per employee attached. The attachment point of the body belt shall be located in the center of the wearer's back. The employer shall provide for prompt rescue of employees in the event of a fall or shall assure that employees are able to rescue themselves. Personal fall arrest systems shall be inspected prior to each use for wear, damage and other deterioration, and defective components shall be removed from service. 1926.503 Training requirements. (a) Training Program (b) Certification of training (c) Retraining Remember: Training, and Supervision 1926 Subpart L - SCAFFOLDS 1926.450 Scope, Application Covers all scaffolds used in workplaces Does not apply to crane or derrick suspended personnel platforms, which are covered by 1926.550(g) Aerial lifts are covered 1926.453 A little planning could have prevented this. 1926.451 General Requirements (a) Capacity – support own weight and 4x the maximum intended load – designed by a qualified person and built and loaded to design 1926.451 General Requirements (continued) (b) Scaffold platform construction – Platforms fully planked or decked – Each abutted end of plank shall rest on a separate support surface – Overlap platforms not less than 12” only over supports, unless restrained to prevent movement 1926.451 General Requirements (continued) (g) Fall protection (Personal Fall – – – – Arrest Systems or guardrails) Required at 10 feet Personal Fall Arrest System required for erectors and dismantlers where feasible Toprails (38” to 45” high) Use crossbracing in lieu of top or midrails in some cases Have a well-trained “Competent Person” on each Site! Inspect Daily and as necessary Scaffolds must only be erected, moved, dismantled and/or altered by qualified workers authorized by the employer Section 1926.454 Training Requirements Five training areas – – – – – Nature of electrical, fall, and falling object hazards Correct procedures for protection of above Proper use of the scaffold Load capacities of scaffolds Requirements of this Subpart Retraining as necessary to restore proficiency 1926 Subpart X - Stairways and Ladders 1926.1052 - Stairways What should be done? 1926.1053 Ladders No Guardrails Unstable Use of Stepladders Standing on Top Steps 1926.1053(b) Use Ladder loading Purpose for use Ladder angle 1926.1053(b) Use Must be inspected by a competent person for visible defects. Withdraw from service until repaired. Tag immediately with "Do Not Use" or similar language. Mark in a manner that readily identifies it as defective. 1926.1053(b) Use Face the ladder when using. Use at least one hand to grasp the ladder when going up and/or down. Do not carry any object or load that could cause you to lose balance and fall. 1926.1060(a) Training requirements The employer must train each employee using ladders and stairways to recognize hazards and the procedures to be followed to minimize these hazards. A competent person must train each employee in the following areas, as applicable: – The nature of fall hazards in the area; – The correct procedures for the fall protection systems to be used; – The proper use of all ladders; – Retrain each employee as necessary to maintain the understanding and knowledge acquired through compliance with this section. Remember: Training, and Supervision 1926 Subpart K - Electrical 403(b)(1) Examination The employer shall ensure that electrical equipment is free from recognized hazards that are likely to cause death or serious physical harm to employees. 403(b)(1) Examination Suitability for installation and use in conformity with the provisions of this subpart - listing, labeling Mechanical strength and durability Electrical insulation Heating effects 1926.403 (d)(1) Mounting Electric equipment shall be firmly secured to the surface on which it is mounted. 1926.403(i)(2) Guarding of live parts Live parts of electric equipment operating at 50 volts or more shall be guarded against accidental contact by cabinets or other forms of enclosures. 1926.404(a)(2) Reverse Polarity Neutral Hot 404(b)(1)(i) General The employer shall use either ground fault circuit interrupters as specified in paragraph (b)(1)(ii) of this section or an assured equipment grounding conductor program as specified in paragraph (b)(1)(iii) of this section to protect employees on construction sites. 405(a)(2)(ii)(E) All lamps for general illumination shall be protected from accidental contact or breakage. 1926.405(a)(2)(ii)(J) Extension cord sets used with portable electric tools and appliances shall be of three-wire type and shall be designed for hard or extra-hard usage. Flexible cords used with temporary and portable lights shall be designed for hard or extra-hard usage. 1926.405(b) Cabinets, boxes, and fittings Conductors entering boxes, cabinets, or fittings shall be protected from abrasion, and openings through which conductors enter shall be effectively closed Unused openings in cabinets, boxes, and fittings shall also be effectively closed Overhead Powerlines Power Line Facts Overhead lines are typically not insulated. Any covering is generally a weather protection, not insulation. Over 90 percent of the contacts occur on overhead distribution lines Operators are normally safe if they stay on the equipment Ground personnel are over 8 times more likely to be killed Maintain Safe Working Clearance 10’ Minimum MINIMUM 10' Distance Remember: Training, and Supervision 1926 Subpart P - Excavations EVERY employee in an excavation shall be protected against cave-ins – Exceptions • stable rock, or • < 5 feet deep AND the Competent Person inspection reveals no indication of potential cave-ins – Protective Systems shall • have capacity to resist loads intended without failure COMPETENT PERSON – one who is capable of identifying existing hazards in the surroundings, or working conditions which are unsanitary, hazardous, or dangerous to employees AND who has authority to CORRECT it IMMEDIATELY. Competent Person Duties Daily Inspections – Competent Person MUST inspect • excavations, • adjacent areas, and • protective systems for: – evidence of conditions that could result in: » possible cave-ins, » failure of protective systems, » hazardous atmospheres, or » other hazardous conditions (1926.651(k)(1)) Competent Person Duties (Cont’d.) When to Inspect – prior to start of work – as needed throughout the shift – after every rainstorm or other occurrence Competent Person Actions – where such hazardous potential is found, “exposed employees shall be removed from the hazardous area until the necessary precautions have been taken to ensure their safety.” (1926.651(k)(2)) DEFINITIONS Excavation – any man-made cut, cavity, trench, or depression in an earth surface, formed by earth removal DEFINITIONS (Continued) Shield – a structure that is able to withstand forces imposed by a cave-in and protect workers DEFINITIONS (Continued) Sloping – method of protecting workers from caveins by excavating to form sides that are appropriately inclined for the soil type being excavated DEFINITIONS (Continued) SOIL CLASSIFICATIONS – Stable Rock - natural solid material that can be excavated with vertical sides and will remain intact – Type A – more than 3,000 pounds per square foot (psf) – Type B – more than 1,000 pounds psf, (< 3,000 psf) – Type C – less than 1,000 pounds psf MOST COMMONLY VIOLATED STANDARDS No Protective Systems Material/Equipment falling in – Spoils/Equipment 2 feet from edge No Daily Competent Person Inspection SPECIFIC REQUIREMENTS Surface Encumbrances – must be removed or supported Underground Installations – location must be determined before excavation begins SPECIFIC REQUIREMENTS (Continued) ACCESS/EGRESS – Stairway, ladder or ramp • no more than 25 feet away • trench more than 4 feet deep SPECIFIC REQUIREMENTS (Continued) Equipment Warning System – barricades, hand/mechanical signals, stop logs if no clear view Hazardous Atmospheres – where oxygen deficiencies or hazardous atmospheres are found or can be reasonably expected, adequate precautions must be taken SPECIFIC REQUIREMENTS (Continued) Water Accumulation – no work in excavations where water is present or accumulating unless adequate precautions have been taken • water removal system must be monitored by Competent Person • special support or shield system • safety harness and lifeline Remember: Training, and Supervision Summery of Objectives Introduction to OSHA Fall Protection Scaffolding, Stairs and Ladders Electrical Hazards Trenching Safety The Golden Rule… It takes the entire crew on the job to recognize, avoid and respond to hazards so everybody goes home safely every day. Safety is everyone’s responsibility – ALL of the time. If you see a Hazard, and would not want someone you love to be exposed to that Hazard for any length of time, that would be a Serious Hazard. Construction Site Safety Presented by: John Able, CSP Occupational Safety Training Specialist CONN-OSHA March 17, 2015