Chapter 35 INTEGRATED MANUFACTURING SYSTEMS

advertisement

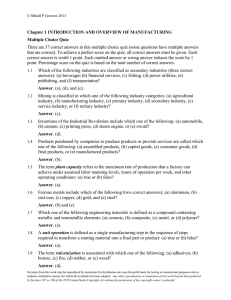

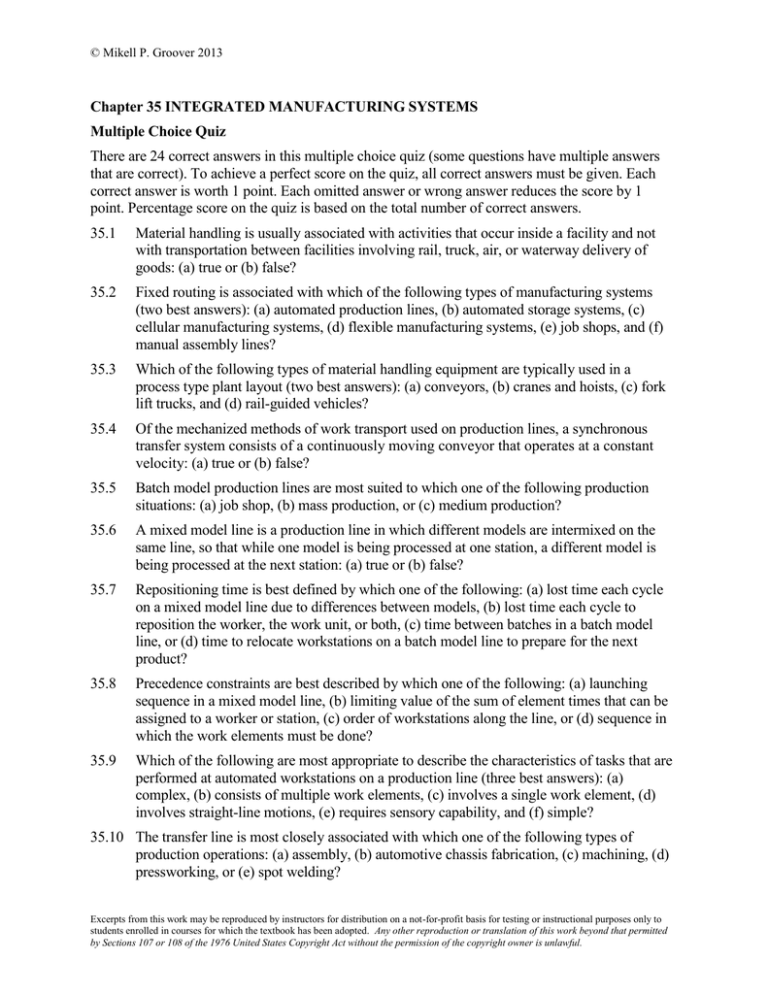

© Mikell P. Groover 2013 Chapter 35 INTEGRATED MANUFACTURING SYSTEMS Multiple Choice Quiz There are 24 correct answers in this multiple choice quiz (some questions have multiple answers that are correct). To achieve a perfect score on the quiz, all correct answers must be given. Each correct answer is worth 1 point. Each omitted answer or wrong answer reduces the score by 1 point. Percentage score on the quiz is based on the total number of correct answers. 35.1 Material handling is usually associated with activities that occur inside a facility and not with transportation between facilities involving rail, truck, air, or waterway delivery of goods: (a) true or (b) false? 35.2 Fixed routing is associated with which of the following types of manufacturing systems (two best answers): (a) automated production lines, (b) automated storage systems, (c) cellular manufacturing systems, (d) flexible manufacturing systems, (e) job shops, and (f) manual assembly lines? 35.3 Which of the following types of material handling equipment are typically used in a process type plant layout (two best answers): (a) conveyors, (b) cranes and hoists, (c) fork lift trucks, and (d) rail-guided vehicles? 35.4 Of the mechanized methods of work transport used on production lines, a synchronous transfer system consists of a continuously moving conveyor that operates at a constant velocity: (a) true or (b) false? 35.5 Batch model production lines are most suited to which one of the following production situations: (a) job shop, (b) mass production, or (c) medium production? 35.6 A mixed model line is a production line in which different models are intermixed on the same line, so that while one model is being processed at one station, a different model is being processed at the next station: (a) true or (b) false? 35.7 Repositioning time is best defined by which one of the following: (a) lost time each cycle on a mixed model line due to differences between models, (b) lost time each cycle to reposition the worker, the work unit, or both, (c) time between batches in a batch model line, or (d) time to relocate workstations on a batch model line to prepare for the next product? 35.8 Precedence constraints are best described by which one of the following: (a) launching sequence in a mixed model line, (b) limiting value of the sum of element times that can be assigned to a worker or station, (c) order of workstations along the line, or (d) sequence in which the work elements must be done? 35.9 Which of the following are most appropriate to describe the characteristics of tasks that are performed at automated workstations on a production line (three best answers): (a) complex, (b) consists of multiple work elements, (c) involves a single work element, (d) involves straight-line motions, (e) requires sensory capability, and (f) simple? 35.10 The transfer line is most closely associated with which one of the following types of production operations: (a) assembly, (b) automotive chassis fabrication, (c) machining, (d) pressworking, or (e) spot welding? Excerpts from this work may be reproduced by instructors for distribution on a not-for-profit basis for testing or instructional purposes only to students enrolled in courses for which the textbook has been adopted. Any other reproduction or translation of this work beyond that permitted by Sections 107 or 108 of the 1976 United States Copyright Act without the permission of the copyright owner is unlawful. © Mikell P. Groover 2013 35.11 A dial indexing machine uses which one of the following types of workpart transfer: (a) asynchronous, (b) continuous, (c) parts passed by hand, or (d) synchronous? 35.12 Production flow analysis is a method of identifying part families that uses data from which one of the following sources: (a) bill of materials, (b) engineering drawings, (c) master schedule, (d) production schedule, or (e) route sheets? 35.13 Most parts classification and coding systems are based on which of the following types of part attributes (two best answers): (a) annual production rate, (b) date of design, (c) design, (d) manufacturing, and (e) weight? 35.14 What is the dividing line between a manufacturing cell and a flexible manufacturing system (one best answer): (a) two machines, (b) four machines, or (c) six machines? 35.15 A machine capable of producing different part styles in a batch mode of operation qualifies as a flexible manufacturing system: (a) true or (b) false? 35.16 The physical layout of a flexible manufacturing system is determined principally by which one of the following: (a) computer system, (b) material handling system, (c) part family, (d) processing equipment, or (e) weight of parts processed? 35.17 In general, industrial robots can most easily handle which one of the following part types in a flexible machining system: (a) heavy parts, (b) metal parts, (c) nonrotational parts, (d) plastic parts, or (e) rotational parts? 35.18 Flexible manufacturing systems and cells are generally applied in which one of the following areas: (a) high-variety, low-volume production, (b) low variety, (c) low volume, (d) mass production, (e) medium-volume, medium-variety production? 35.19 Which one of the following technologies is most closely associated with flexible machining systems: (a) lasers, (b) machine vision, (c) manual assembly lines, (d) numerical control, or (f) transfer lines? Excerpts from this work may be reproduced by instructors for distribution on a not-for-profit basis for testing or instructional purposes only to students enrolled in courses for which the textbook has been adopted. Any other reproduction or translation of this work beyond that permitted by Sections 107 or 108 of the 1976 United States Copyright Act without the permission of the copyright owner is unlawful.