The use of a conical lime reactor to control the

advertisement

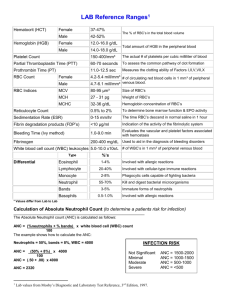

The use of a conical lime reactor to control the pH of drinking water in small scale water treatment systems Kavita Mahulikar and Taylor Reiss Cornell University 10 December 2005 objective Counteract the pH lowering effects of alum through the addition of lime in a small scale water treatment plant objective Why? Honduras Water Supply Project uses alum during flocculation Alum lowers the pH of the water Want to deliver clean, safe water of pH > 6 objective How? Calcium Oxide (CaO) “lime” Saturation pH ≈ 12.4 • High acid neutralizing capacity (ANC) • Readily available in Honduras • Conical Reactor • Direct part of plant flow into reactor • Maintain consistent effluent pH around 12 design From Schult, Christopher R., and Okun, Daniel A. Surface Water Treatment for Communities in Developing Countries.” Great Britain: Intermediate Technology Publications, 1984. design Reactor 1 Reactor 2 •Diameter ≈ 7 cm •Diameter ≈ 3 cm •Bottom was too flat, not ideal cone shape •Closer to ideal cone shape •Difficult to keep particles in suspension D •Easier to maintain lime “blanket” design pH Probe Pressure Sensor Flow Accumulator Solenoid Valve effluent Metal Influent Tube B e n c h Collection Tank CaCO3 Waste To Plant L a b Tap Water design Experiment 1 • Q = 350 mL/min • CaO dose = 178 g results pH as a function of time 13 pH 12 11 10 9 8 0 3 6 Time (hr) 9 12 Experiment 1 • Q = 350 mL/min • CaO dose = 178 g results pH and ANC as a function of time 0.06000 12.60 12.55 0.05000 12.50 12.45 12.40 0.03000 12.35 0.02000 12.30 12.25 0.01000 12.20 0.00000 0.00 12.15 1.00 2.00 3.00 4.00 Time (hr) ANC pH 5.00 6.00 7.00 pH ANC (eq/L) 0.04000 Experiment 2 • Q = 200 mL/min • CaO dose = 178 g results pH as a function of time 13 12 pH 11 Series1 10 9 8 0 3 6 Time (Hr) 9 12 Experiment 2 • Q = 200 mL/min • CaO dose = 178 g results pH and ANC as a function of time 0.04500 13.00 0.04000 12.50 0.03000 12.00 0.02500 11.50 0.02000 0.01500 11.00 0.01000 10.50 0.00500 0.00000 10.00 0 2 4 6 8 10 12 14 16 18 Time (hr) Initial ANC After Mixing ANC pH 20 22 24 pH ANC (eq/L) 0.03500 results ANC as a function of time 0.06000 ANC (eq/L) 0.05000 0.04000 0.03000 0.02000 0.01000 0.00000 0.00 1.00 2.00 3.00 4.00 5.00 Time (hr) Q = 350 mL/min Q = 200 mL/min 6.00 7.00 results Why? ↓ flow rate = ↓ exit velocity Difficult to keep particles in suspension over time Lime has low solubility, thus, ANC is directly related to concentration of particles As particles settle out, ANC goes down At 200 mL/min, there was a lot of lime that never left the reactor analysis ANC Calculations ANC HCO3 2 CO32 OH H 1moleCaO 1moleCa(OH ) 2 2moles(OH ) 178 gCaO 6.34moles(OH ) 56.1gCao 1moleCaO 1moleCa(OH ) 2 OHInitial OHafter 7 hours OHafter 4 days 1 Q = 350 mL/min 6.34 moles 2.78 moles N/A 2 Q = 200 mL/min 6.34 moles 4.4 moles 2.54 moles Experiment analysis Feasibility Assuming: Alum dose = 40 mg/L Average reactor effluent ANC = 0.035 eq/L Q = 350 mL/min Then: Max. Plant Flow Rate = 30.5 L/min analysis Feasibility Potential Problems: Unstable System Calcium Carbonate (CaCO3) Removal conclusion Our experimental design is not feasible for small scale water supply in Honduras But maybe someday… conclusion Possible Alternatives Use a base with a higher solubility Larger Reactor, higher residence time