AT_seminar_presentation_20130207_v024 - Indico

advertisement

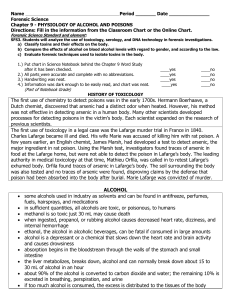

Maintenance Management Project Pierre Bonnal Christophe Delamare Marine Gourber-Pace Damien Lafarge Christophe Mugnier Goran Perinić Regis Pilon Ingo Ruehl Eric van Uytvinck David Widegren Zornitsa Zaharieva DG-DI GS-ASE BE-CO EN-HE TE-EPC TE-CRG TE-EPC EN-HE EN-EL GS-ASE BE-CO Maintenance Management Project A&T Seminar th 7 February 2013 Contents Can we still improve maintenance at CERN? The Maintenance Management Project (MMP) All clear? 07.02.2013 G. Perinić and the MMP team 3 07.02.2013 G. Perinić and D. Lafarge for the MMP team 4 repair efficiently OR: Do any of these problems sound familiar to you? Jan: “Where is the electric distribution 07.02.2013 G. Perinić and D. Lafarge for the MMP team box located?” 5 • Start – problem identified – WO or intervention ticket created e.g. by control room staff • Step 1 – checking the WO or intervention ticket Step 2 – checking the information for the equipment • • Step 3 – closing the WO or intervention ticket after repair/intervention 07.02.2013 Mobile device connected by WLAN or GSM. Application running in browser. Platform independent! G. Perinić and D. Lafarge for the MMP team 6 Building blocks repair efficiently 1. Register your equipment Collect and register your spare part data have the right spares have the data in a common DB 07.02.2013 G. Perinić and D. Lafarge for the MMP team 7 Building blocks repair efficiently 1. Register your equipment Collect and register your spare part data 2. Format and upload documentation have the right spares have the data in a common DB have the documen -tation 07.02.2013 G. Perinić and D. Lafarge for the MMP team 8 Building blocks repair efficiently 1. Register your equipment Collect and register your spare part data 2. Format and upload documentation 3. Benefit from CERN workflows have the right spares have the data in a common DB have the documen -tation have efficient processes 07.02.2013 know the equipment history G. Perinić and D. Lafarge for the MMP team 9 07.02.2013 G. Perinić and D. Lafarge for the MMP team 10 Key Performance Indicators and Criticality Analysis analyze historic data 100 90 99 80 98 70 97 60 96 50 95 40 94 30 93 20 92 10 91 0 27-Feb Cumulated availability Availability 100 predict 90 26-Mar Scheduled Stops 23-Apr 21-May Daily 2012 18-Jun 16-Jul Weekly 2012 13-Aug 10-Sep Between TS 2012 8-Oct 5-Nov 3-Dec Cumulated 2012 measure and predict 07.02.2013 G. Perinić and Damien Lafarge for the MMP team 11 Building blocks • • • • • repair efficiently Register your equipment improve the reliability Collect and register your spare part data make the Format and upload documentation right consolidation Benefit from CERN workflows decisions Choose strategy • • • • Run to failure Preventive maint. Predictive maint. Consolidate 07.02.2013 have the right spares have the data in a common DB choose the right strategy have the documen -tation have efficient processes know the equipment history measure and predict G. Perinić and D. Lafarge for the MMP team 12 07.02.2013 G. Perinić and D. Lafarge for the MMP team 13 Organization of the MMP Steering Board I. Rühl, G. Perinić Project coordination Department Heads BE, EN, TE, GS Task force members M. GourberPace BE Maintenance Project C. Mugnier TE Maintenance Project 07.02.2013 D.Lafarge EN Maintenance Project P. Bonnal, Z. Zaharieva Maint. Mngmt. QA System G. Perinić and D. Lafarge for the MMP team C. Delamare CMMS Development Project 14 Main objectives of the MMP Asset management • Identify & manage 95%* of A&T sector’s critical equipment and 50%* of all A&T sector’s equipment Information management • Define and manage the documentation and data that is necessary for the maintenance of above equipment Work management • Implement harmonized workflows Maintenance planning • Implement maintenance plans for critical assets Reporting and analysis • Provide KPIs for the critical assets 07.02.2013 G. Perinić and D. Lafarge for the MMP team 15 Impact of the MMP doing imposing replacing maintenance reducingall maintenance the software for you or staff budgets methods tools at your place THE THEPROJECT PROJECTISISABOUT NOT ABOUT 07.02.2013 G. Perinić and the MMP team 16 A further motivation “[…], there is no common, coherent approach to maintenance across groups, to ensure a reliable operation of the LHC machine and its injectors […]“ “[…] all equipment groups should follow well defined and coherent procedures for planning and performing maintenance and for storing maintenance data in a centralized system. [...]” “Audit of the operation of LHC and its injectors” (ref. DG-IA/10-R5 20th Dec. 2011) 07.02.2013 G. Perinić and D. Lafarge for the MMP team 17 CMMWG CMMSB Aug 2010 internal TE audit (C. Mugnier) audit in 4 groups (BalticBerg) Status of the MMP in HERMES MFIO implementation July 2012 MMP Concept Report May 2012 MMP Roadmap Feb 2012 Maintenance workshop Nov 2011 07.02.2013 G. Perinić and D. Lafarge for the MMP team 18 1 2 3 4 56789 • Common key-definitions • A common naming/coding reference • Description of maintenance processes in BPMN • The issue concept • The maintenance information concept • The metadata and search concept • Criticality ranking system • The roles concept • The Maintenance Framework Implementation Office concept MMP Concept Report EDMS 1173942 07.02.2013 G. Perinić and D. Lafarge for the MMP team 19 The roles concept for a modern maintenance organisation at CERN 07.02.2013 8 • A group quality/methods officer role (GQMO): Promoting policy, procedures and standards for maintenance management and implementing a QA system at group level. • A group maintenance information officer role (GMIO): Promoting good practices. Guaranteeing that all the maintenance information (document and data) is coherently managed. • A group coding officer role (GCO)): Link person with the Naming Service for attribution of equipment codes. Promoting good practices in matter functional position, item/part and asset coding and guaranteeing that coding is coherently implemented at group level. • A group spare part officer role (GSPO): Promoting good practices. Providing support for managing spare part processes and ensuring that spare parts are coherently managed at group level. G. Perinić and D. Lafarge for the MMP team 20 implementation & deployment in groups group coding officer group maint. information of. group spare part officer X X s X s group quality/methods officer s X X X X X X X 07.02.2013 X X X X X X X X X X X X G. Perinić and D. Lafarge for the MMP team X X Jaime PEREZ E. Fabien ANTONIOTTI Eric PAGE Alexandre SINTUREL Régis Pilon Patrice BAILLY Marc BOMONT TE-VSC TE-EPC TE-CRG TE-ABT EN-STI EN-MEF EN-HE EN department Ludovic Germain-Bonne Sigrid KNOOPS Nicolas BONETTI Remy NOULIBOS Tony Fowler Oliver ABERLE Samy CHEMLI Jean Maurice CHEVALLEY Damien LAFARGE EN-EL EN-CV BE-CO BE department Eric VAN UYTVINCK Soren POULSEN Guillermo PEON Zory ZAHARIEVA Claude DEHAVEY Sylvestre CATIN The roles concept for a modern maintenance organisation at CERN 8 TE department X X X X X X 21 Courses, seminars and workshops • Maintenance management course Day 1 1) Introduction to maintenance, strategies and tools 2) Maintenance organization 3) Maintenance and reliability improvement projects 4) Preventive maintenance basics 5) Spare parts and maintenance supply chain management • • Presentations in SLMs Day 2 1) Asset management basics 2) Maintenance information and documentation management 3) Maintenance performance measurement and analysis 4) Analysis tools in maintenance and reliability - basics 5) Hands on workshop - Criticality analysis Asset and maintenance management workshop for international research laboratories at CERN 13th -15th November 2013 Target: European accelerator, fusion and large scale laboratory community 07.02.2013 G. Perinić and D. Lafarge for the MMP team 22 improve the reliability have the right spares make the right consolidation decisions have the data in a common DB have the right strategy have the documen -tation measure and predict 07.02.2013 repair efficiently have efficient processes G. Perinić and D. Lafarge for the MMP team know the equipment history 23 We are there to help you! Your first line of contact is the Maintenance Framework Implementation Office mfio@cern.ch http://cern.ch/maintenance Further support will be provided as required by: Layout and naming service: Accelerators-Naming.Service@cern.ch http://cern.ch/service-acc-naming EDMS: EDMS.support@cern.ch http://cern.ch/edms-services CMMS: CMMS.support@cern.ch http://cern.ch/cmms-service 07.02.2013 G. Perinić and the MMP team 24