slip length

advertisement

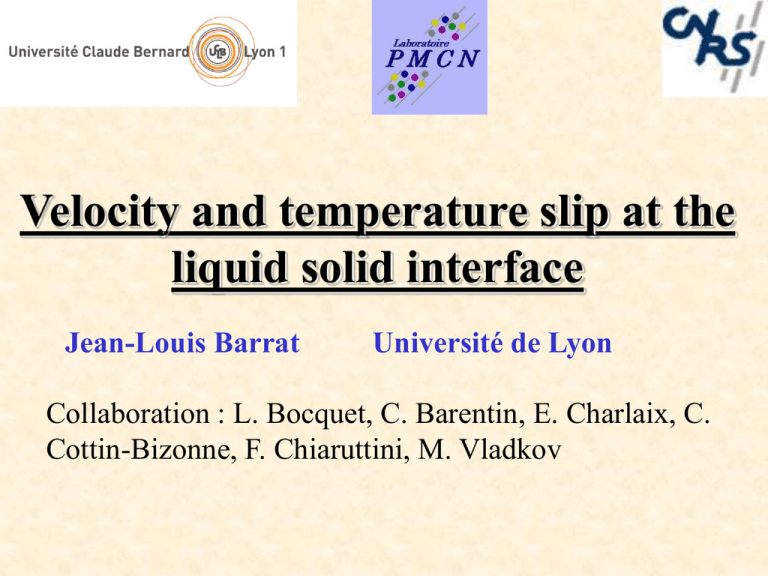

Velocity and temperature slip at the liquid solid interface Jean-Louis Barrat Université de Lyon Collaboration : L. Bocquet, C. Barentin, E. Charlaix, C. Cottin-Bizonne, F. Chiaruttini, M. Vladkov Outline • • • • • • Interfacial constitutive equations Slip length Kapitsa length Results for « ideal » surfaces Slip length on structured surfaces Thermal transport in « nanofluids » Hydrodynamics of confined fluids Original motivation: lubrication of solid surfaces Mechanical and biomechanical interest Fundamental interest: •Does liquid stay liquid at small scales? •Confinement induced phase transitions ? •Shear melting ? •Description of interfacial dynamics ? Controlled studies at the nanoscale: Surface force apparatus (SFA) Tabor, Israelaschvili Bowden et Tabor, The friction and lubrication of solids, Clarendon press 1958 D. Tabor Micro/Nano fluidics (biomedical analysis,chemical engineering) Lee et al, Nanoletters 2003 Microchannels ….Nanochannels Importance of boundary conditions INTERFACIAL HEAT TRANSPORT •Micro heat pipes •Evaporation •Layered materials •Nanofluids Hydrodynamic description of transport phenomena 1) Bulk constitutive equations : Navier Stokes, Fick, Fourier Physical material property, connected with statistical physics 2) Boundary conditions: mathematical concept Replace with notion of interfacial constitutive relations Physical, material property, connected with statistical physics Interfacial constitutive equation for flow at an interface surface: the slip length (Navier, Maxwell) V S VS z b Continuity of stress = viscosity V VS b z = friction micro-channel : S/V~1/L surface effect becomes dominant. Influence of slip: Poiseuille Flow rate is increased Hydrodynamic dispersion and velocity gradients are reduced. E Also important for electrokinetic electric field phenomena (Joly, Bocquet, Ybert 2004) - - - - + + + + + Electroosmosis v + -+ Electrostatic double layer ~ nm - 1µm Interfacial constitutive equation for heat transport Kapitsa resistance and Kapitsa length Thermal contact resistance or Kapitsa resistance defined through Kapitsa length: lK = Thickness of material equivalent (thermally) to the interface Important in microelectronics (multilayered materials) solid/solid interface: acoustic mismatch model Phonons are partially reflected at the interface Energy transmission: Zi = acoustic impedance of medium i See Swartz and Pohl, Rev. Mod. Phys. 1989 Experimental tools: slip length SFA (surface force apparatus) Drag reduction in capillaries Churaev, JCSI 97, 574 (1984) Choi & Breuer, Phys Fluid 15, 2897 (2003) AFM with colloidal probe Craig & al, PRL 87, 054504 (2001) Bonnacurso & al, J. Chem. Phys 117, 10311 (2002) Vinogradova, Langmuir 19, 1227 (2003) v Optical tweezres Optical methods:: PIV, fluorescence recovery Evanescnt wave Experiments often difficult – must be associated with numerical:theoretical studies Some experimental results Slip length (nm) Tretheway et Meinhart (PIV) Pit et al (FRAP) Churaev et al (perte de charge) Craig et al(AFM) Bonaccurso et al (AFM) Vinogradova et Yabukov (AFM) Sun et al (AFM) Chan et Horn (SFA) Zhu et Granick (SFA) Baudry et al (SFA) Cottin-Bizonne et al (SFA) Nonlinear 1000 100 10 1 MD simulations 0 50 100 Contact angle (°) 150 Simulation results (intrinsic length: ideal surfaces, no dust particles, distances perfectly known) •Robbins- Thompson 1990 : b at most equal to a few molecular sizes, depending on « commensurability » and liquid solid interaction strength •Barrat-Bocquet 1994: Linear response formalism for b •Thompson Troian 1996: boundary condition may become nonlinear at very high shear rates (108 Hz) •Barrat Bocquet 1997: b can reach 50-100 molecular diameters under « nonwetting » conditions and low hydrostatic pressure •Cottin-Bizonne et al 2003: b can be increased using small scale « dewetting » effects on rough hydrophobic surfaces b Linear response theory (L. Bocquet, JLB, PRL 1994) Kubo formula: Density at contact. Associated with wetting properties Response function of the fluid Corrugation Note: the slip length is intrinsically a property of the interface. Different from effective boundary conditions used for porous media (Beavers Joseph 1967) Density at contact is controlled by the wetting properties and the applied hydrostatic pressure. b/ q=140° q=90° P/P0 Density profiles P0~MPa Slip length as a function of pressure (LennardJones fluid) A weak corrugation can also result in a large slip length. SPC/E water on graphite Contact angle 75° Direct integration of Kubo formula: b = 18nm (similar to SFA experiments under clean room conditions – Cottin Steinberger Charlaix PRL 2005) Analogy: hydrodynamic slip length Kapitsa length Energy Momentum ; Temperature Velocity ; Energy current Stress Kubo formula q(t) = energy flux across interface, S = area Results for Kapitsa length -Lennard Jones fluids Wetting properties controlled by cij -equilibrium and nonequilibrium simulations Nonequilibrium temperature profile – heat flux from the « thermostats » in each solid. Equilibrium determination of RK Heat flux from the work done by fluid on solid Dependence of lK on wetting properties (very similar to slip length) J-L Barrat, F. Chiaruttini, Molecular Physics 2003 Experimental tools for Kapitsa length: Pump-probe, transient absorption experiments for nanoparticles in a fluid : -heat particles with a « pump » laser pulse -monitor cooling using absorption of the « probe » beam Time resolved reflectivity experiments Influence of roughness (slip length) Far flow field – no slip Richardson (1975), Brenner Fluid mechanics calculation – Roughness suppresses slip Perfect slip locally – rough surface But: combination of controlled roughness and dewetting effects can increase slîp by creating a « superhydrophobic » situation. 1 µm D. Quéré et al Simulation of a nonwetting pattern Ref : C. Cottin-Bizonne, J.L. Barrat, L. Bocquet, E. Charlaix, Nature Materials (2003) Superhydrophobic state « imbibited » state Hydrophobic walls q = 140° Pressure dependence Flow parallel to the grooves (similar results for perpendicular flow) Superhydrophobic imbibited b (nm) rough surface * flat surface P/Pcap Macroscopic description (C. Barentin et al 2004; Lauga et Stone 2003; J.R. Philip 1972) Vertical shear rate: Inhomogeneous surface: Far field flow is the slip velocity Complete hydrodynamic description is complex (cf Cottin et al, Eur. Phys. Journal E 2004). Some simple conclusions: Partial slip + complete slip, small scale pattern b1>>L Works well at low pressures (additional dissipation associated with meniscus at higher P) Partial slip + complete slip, large scale pattern b1 << L L= spatial scale of the pattern a= lateral size of the posts Fs = (a/L)2 Area fraction of no-slip BC a Scaling argument: Force= (solid area) x viscosity x shear rate Shear rate = (slip velocity)/a Force= (total area) x (slip velocity) x (effective friction) How to design a strongly slippery surface ? For fixed working pressure (0.5bars) size of the posts (a=100nm), and value of b0 (20nm) Compromise between Large L to obtain large z Pcap large enough P<Pcap 1/( L) Possible candidate : hydrophobic nanotubes « brush » (C. Journet, S. Purcell, Lyon) Contact angle 180 degrees P. Joseph et al, Phys. Rev. Lett., 2006, 97, 156104 Effective slippage versus pattern: flow without resistance in micron size channel ? (Joseph et al, PRL 2007) v/v0 0.4 0.2 0 -2 0 2 4 6 v/v0 0.4 0.2 beff ~ µm 0 -2 0 2 4 6 z (µm) v/v0 L beff 0.4 Characteristic size 0.2 L 0 -2 0 2 z (m) 4 6 Very large (microns) slip lengths observed in some experiments could be associated with: •Experimental artefacts ? •Impurities or small particles ? •Local dewetting effects, « nanobubbles » ? Tyrell and Attard, PRL 2001 AFM image of silanized glass in water Thermal transport in nanofluids • Large thermal conductivity increase reported in some suspensions of nanoparticles (compared to effective medium theory) • No clear explanation • Interfacial effects could be important into account in such suspensions Simulation of the cooling process •Accurate determination of RK: fit to heat transfer equations •No influence of Brownian motion on cooling Simulation of heat transfer hot Maxwell Garnett effective medium prediction a = (Kapitsa length / Particle Radius ) Cold M. Vladkov, JLB, Nanoletters 2006 Effective medium theory seems to work well for a perfectly dispersed system. Explanation of experimental results ? Clustering, collective effects ? (² /) exp / (² /) 2 phases model 1000 Au ??? Cu MW CNT 100 10 1 0,1 0,01 Al2O3 CuO TiO2 Fe Our MD Au 0,1 1 10 Volume fraction Effective medium calculation for a linear string of particles Similar idea for fractal clusters (Keblinski 2006) Still other interpretation: high coupling between fluid and particle (Yip PRL 2007) and percolation of high conductivity layers (negative Kapitsa length ?) Conclusion • Rich phenomenology of interfacial transport phenomena: also electrokinetic effects, diffusio-osmosis (L. Joly, L. Bocquet) • Need to combine modeling at different scales, simulations and experiments