Presentation - Wisconsin Transportation Center

advertisement

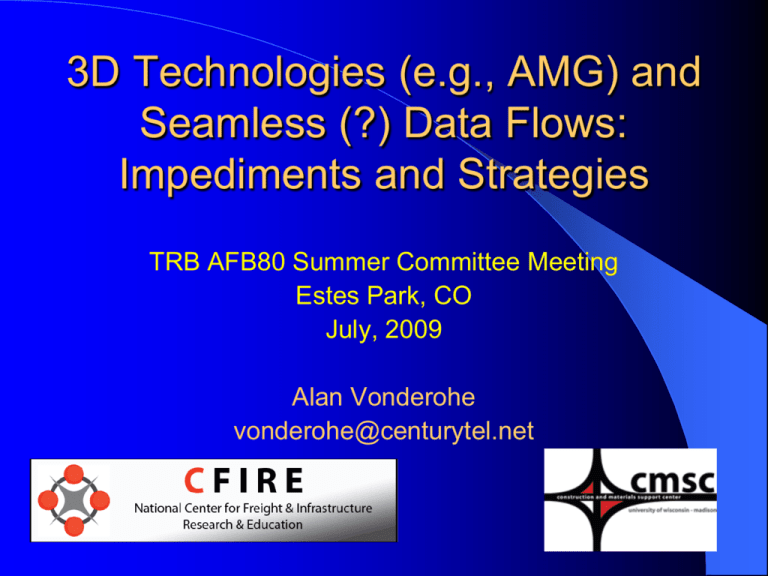

3D Technologies (e.g., AMG) and Seamless (?) Data Flows: Impediments and Strategies TRB AFB80 Summer Committee Meeting Estes Park, CO July, 2009 Alan Vonderohe vonderohe@centurytel.net Outline AMG Specification Development. 3D Technologies Implementation Planning. Data Flow Obstacles: Design / Contracting / Construction. Outline How AFB80 Can Help. – Educational Aspects. – Technological Aspects. – Institutional Aspects. – Legal Aspects. AMG Subgrade Specification Development Process (WisDOT/CMSC) 2006 Advisory Group Literature Review and Industry Survey 2009 Final Specification Contractor and Region Interviews Specification Framework 1st Specification 2nd Specification 2nd Pilot Projects Stakeholder Workshop 2007 1st Pilot Projects 2008 Subgrade Specification Components No subgrade stakes required. Engineer can require reversion to conventional methods. Contractor’s GPS work plan: – Equipment; staff qualifications; project control; site calibration and checks; equipment calibration; subgrade checks. 3D model: – Department provides “survey package” of digital data. – 3D model building is contractor’s responsibility; 2D plans are the contract documents; initial model and revisions provided to department. Subgrade Specification Components Site calibration: – Greater of 6 control points or 2 per mile; daily checks at independent control to be within ±0.10 ft. horizontally and ±0.05 ft. vertically. Subgrade checks (against plans, not model): – 20 or more per roadway mile, project, or stage; randomly selected full stations; 4 of any 5 consecutive must be within ±0.10 ft. of plan elevation; engineer observes and uses for approval; engineer can make and / or require additional subgrade checks. Current and Future Expectations for AMG Specs Specification is optional special provision replacing subgrade staking as bid item on all 2009 projects that include grading. Will become component of general specifications for 2010 and beyond. WisDOT will monitor performance of subgrade spec while embarking on development of spec for base course, then paving. WisDOT deploying 3D design technology – headed towards delivery of 3D models as design product. Training provided to 80 project engineers (2008, 2009). More training expected over next 2-3 years. 3D Technologies Implementation Planning 2008: WisDOT implementing AMG and 3D design software and processes. – Preliminary study on wider use of 3D models throughout design and construction. – Stakeholder workshop on interim report: AMG and 3D design among larger group of 3D technologies and processes interrelated by dependencies, synergistic benefits, and shared impediments. – Undertook broader effort to develop implementation plan for 3D technologies for design and construction in general. 3D Technologies Implementation Planning Plan components: – Vision statement. – Six Initiatives (on-going or proposed) with backgrounds, issues, stakeholders, recommendations, goals, timelines, levels of effort, priorities, benefits, relationships with other initiatives, and responsible parties. – Dependencies among initiatives and goals. – Umbrella management strategy. 3D Technologies Implementation Planning Vision statement: “Adoption of 3D methods and seamless data flows throughout initial survey, design, contracting, construction, as-built survey, payment, and other applications included within the infrastructure lifecycle.” – Opens the door beyond design and construction. Initiatives, Goals, Timelines, Priorities Initiatives, Goals, Timelines, Priorities 3D Technologies Implementation Planning Dependencies among initiatives: 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 Height Modernization and ContinuouslyOperating Reference Stations Field Technology and Inspection DTM Data Collection 3D Design Automated Machine Guidance NOTE: An arrow indicates that if goals of the antecedent initiative are not met, then benefits of the subsequent initiative will be diminished. Infrastructure Lifecycle Uses of 3D Data HMP and CORS Secure Funding DTM Data Collection Develop Standards & Procedures DTM Data Collection Fill Survey Data Coordinator Positions HMP and CORS Implement 5-Year Completion Plan DTM Data Collection Pilot Standards & Procedures DTM Data Collection Revise Map Check Business Practice 3D Design 3D Models for PS&E 3D Design 3D Model Standards 3D Design Existing PreDeployment Plan DTM Data Collection Implement Standards & Procedures AMG Base Course and Paving Specs Field Technology and Inspection Implement Rovers for Construction Dependencies among goals. DTM Data Collection Implement DTM-toDTM for Earthwork Field Technology and Inspection Feasibility Studies 3D Design Extended Deployment Plan Field Technology and Inspection Implementation Plans Field Technology and Inspection Implement Inspection Automation Infrastructure Lifecycle Uses of 3D Data Notes: 1) Initiative titles appear in bold font. 2) An arrow indicates diminished likelihood of meeting the subsequent goal if the antecedent goal is not met. Management Strategy Recommendations: Appoint a 3D Technologies Management Group, chaired by a bureau director: Coordinates recommended activities. Provides reporting structure. Keeps upper-level management informed. Advocates for overall effort. Develops outreach mechanisms. Management Group includes at least one representative from each initiative. Implementation plan updated at least annually by Management Group. Seamless Data Flows: Impediments and Strategies Nationwide study funded by Center for Freight Infrastructure Research and Education (CFIRE) at UWMadison. Project is mid-stream. Target is this predicament: Here’s what we do. Here’s what we should do. Seamless Data Flows: Impediments and Strategies Approach: – Literature search. – Nationwide survey. – 3-4 case studies. – Earthwork volumes methods comparison (average-end-area vs surface-to-surface). – Design software functionality descriptions. – Guidelines and recommendations. Web-Based Survey Being tested by AASHTO Technology Implementation Group on AMG. Will go to remaining 42 states by midAugust. Three sections (37 questions): Design, Contracting, Construction. 30-45 minutes to complete. Availability of Materials Project reports, specification, guidance language, implementation plan, and training materials available right here on my thumb drive and all the time at – http://cmsc.engr.wisc.edu/reports.html How This Committee Can Help Four areas: – Educational. – Technological. – Institutional. – Legal. Educational Needs Principles and practice of: – RTK GNSS positioning. – CORS-based RTK positioning. – Automated machine guidance. Target audience: – Project engineers and contractors. – Recall that many engineering curricula no longer include courses in even basic surveying. Web-based delivery for wide access. Technological Needs Test and demonstration of CORS support for AMG. QA/QC procedures for AMG and associated model specs. Guidelines / framework for state-level development of 3D model content and format standards. Guidelines for engineering-scale DTM data collection. Institutional Needs Benefits of AMG to state DOTs and, ultimately, taxpayers. – Are the productivity gains realized by contractors passed on to DOTs? – Are the benefits to DOTs tangible and quantifiable? – Why should DOTs develop specifications for AMG? Legal Needs “The downside is that if the model is expressly subordinate to traditional construction documents, the model cannot be relied upon during the pricing and construction process…” Thomson and Miner (2006), in reference to building information modeling (BIM) Stay Abreast of and Support NCHRP 10-77 (pending): Use of Automated Machine Guidance (AMG) within the Transportation Industry. “The objective of this research is to develop guidelines for use of AMG…guidelines should (1) include technical procurement specifications for AMG technology; (2) provide guidance on use of such technology in construction projects; and (3) address implementation of AMG technology into construction techniques (including provision of electronic files and models to support the AMG process).” TRB Website