Electronic Files and Design Data

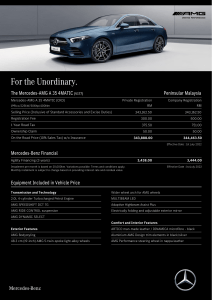

advertisement

Automated Machine Guidance: Electronic Files and Design Data AASHTO Subcommittee on Construction Meeting August 18, 2010 – Burlington, VT Mark Taylor 1 Cross-Sections vs. Surfaces • We traditionally design and build accurately at each cross-section • We now have the capability to design and build accurately everywhere • However, construction can only be as accurate as the survey data and controls • Construction control tolerance is not any more precise than the design 3D surface model 2 Design Today: Cross SectionBased 3D Design Modeling 3 3D Design Surface Layers • • • • • Finished surface (top of pavement) Aggregate base (bottom of pavement) to foreslope Aggregate subbase layers (if any) Subgrade surface from slope stake to slope stake Subexcavation or wall foundations (undercut) 4 3D Design Model Work Flow • • • • • • • Develop the geometric design information Prepare cross sections for design model Generate 3D design surface model (TIN) Check the 3D surface tolerances Verify the 3D surface path Spot check xyz of the TIN Clip the existing terrain and merge the design and terrain surface models • Export the combined 3D surface models – Generate file formats for the Contractor 5 Electronic File Formats • ASCII (generic software) • Land XML (Topcon software) • Trimble (Trimble Terramodel and Sitevision software) – Trimble .TTM format 6 Pattern Lines for 3D Design Model 7 Pattern Lines for 3D Model • Interval spacing is dependent on the radius of curvature • Add sections at the beginning and end of superelevation transitions • At begin and end of widening transitions, including for traffic barrier terminals • At begin and end of road approach intersections • Changes in ditch configuration and inlets 8 Chords Between Sections 9 3D Design Model Tolerances Design Element Horizontal (X and Y coordinates) Vertical (Z coordinate) Roadway template points ±0.04 ft ±0.01 ft Roadside ditch and other slope points ±0.1 ft ±0.05 ft 10 Rec’d Pattern Line Spacing Pattern Line Spacing* Horizontal Curve Radius Vertical K Value 10 ft ≥ 300 ft and tangents ≥ 13 and tangents 5 ft 75 ft < 300 ft 6 < 13 2 ft < 75 ft <6 *Also at centerline points (PC, PT etc.) and at superelevation and widening transitions for final design 11 Cross-Sections for 3D Design Model 12 Template Surface Points Subgrade Layer 13 Connect Similar Cross-Section Point Labels Using Breaklines 14 Transitions (Cut to Fill) 15 Cut to Fill Breaklines 16 An Ideal World • The Design engineer provides the Contractor a complete 3D model that fits site conditions • Contractor easily loads 3D surface model directly into the machine guidance system • The Contractor builds project accurately to the plans, specifications, and tolerances • Any changes or revisions are updated in the 3D surface model by the project engineer • As-built 3D surface model is given back to the owner (State DOT) 17 The Real World • Existing ground data does not match to site conditions or with 3D design surface model • Missing data, information and details about exceptions to the model – Lack of detail at intersections and culvert inlets and outlets requires manual adjustments and warping – Ditch profiles do not match with culvert inlets or site conditions – Special ditch information is shown in the plans profile but is not in the 3D design surface model • Specifications do not fully address the work 18 Design Changes for 3D/AMG • Cross section pattern lines at closer intervals (typically 10-feet instead of 50-feet) to achieve the required accuracy in the 3D surface • Proficiency with special applications of the design software to generate the 3D surface • Time-intensive activities associated with these new applications are: – Hand–editing any cross-sections that cannot be drawn with standard criteria (modify text search) – QC checks of the 3D surface between pattern lines 19 Changes for 3D/AMG cont’d • Contract special provisions – How to resolve discrepancies between the electronic data and the contract plans – Responsibility for changes to electronic data • Achieving a common understanding of the concepts and limitations in the design model – Exceptions (what is not modeled) – Degree of accuracy and precision – Discontinuities (linear changes and transitions) 20 Construction Changes for AMG • Understanding the concepts and limitations of the electronic 3D design model (exceptions, degree of accuracy) • Understanding the AMG accuracy limitations • Performing the necessary layout, inspection activities with less “wood in the ground” • Using suitable survey equipment and methods for layout, inspection activities, and for independent QA of the Contractor’s AMG methods 21 22 Challenges for 3D Design • Modeling guidance and training is needed • Standards for the 3D model deliverables – Design data files that are provided – Electronic data formats • • • • • • Professional liability/Engineer of record Consistency, uniformity, quality control Quantities calculation and documentation QA/QC of 3D data (DTM, design data files) Field verification and changes to design data Documentation of as-built project features 23 RRR Projects: Challenges for 3D Design Modeling • Procedures and specifications for using design models derived from resource-grade survey and mapping technologies • Develop end-result, performance based methods and specifications for control, rather than strict line and grade position • Allow flexibility and foster innovation • Expedite production and reduce costs 24 Standards and Procedures • When to develop 3D design models for AMG? • How to develop the model? – What features to include? – How many layers? – What level of detail? • What format to provide the model for others to use? • How to manage changes to the as-built design model? • How to document and retain electronic records? 25 Caution: Automated Computer Design Plus Machine Guidance 26