DM Start

Off-Shoring, On-Shoring -

SCM As A Core

Competency

APICS Terra Grande District

Houston, TX

March 1, 2012

Bob Forshay, VP

Transformance Advisors Inc.

Learn

Apply

Agenda

Evaluate – Debate

Why We Do This?

Group Exercise

Impacts,

+

or

–

Examples

What If?

Call To Action

Summary

Off Shore Impacts?

Pros

Lower Labor Costs

Business Incentives

Lower Materials Costs

Volume Buy Price

Low Unit Cost?

Partial History

Laptop Batteries - Fires

Pet Food Contaminated - Deaths

Lead Paint on Toys - Deaths

Drywall Contaminated – Sickness

Business Lost to Pirating - Revenue

Embedded Security Risks – Security

How do you proactively manage the risks?

What is the real cost?

Business Impacts?

Cons Cons

Lead time Risk

- Greater Inventory Risk?

Information Risk

- Communication?

- Quality Processes?

- Quality Reporting?

- Quality Management?

- Change Management?

Management Risk

- Sourcing Integrity?

- IP stolen w/i 6 months

Transportation Risk

- Logistics Controls?

- Import/Export Costs?

Capacity Risk

- Uncertain Commitment?

- Volume to Justify?

- Cost of Change?

Service & Repair Cost?

- LT to Service?

- Separate Facility/Skills?

Disruption Risk

- Triage & Recovery

- Relocating key personnel?

Economy (foreign) Risk

Exchange Rate Risk

Customer Confidence Risk

Market Risk

Social Impacts?

Subpar Labor Practices

Low compliance to work standards

Fraudulent audits

Child labor est. 4-5%

10-20% turnover/month

12-18 hour shifts

Union worker complaints = reason to fire

Suicides increased - higher than average

Epidemic of chemical poisoning incidence

US Worker

Earning Potential – Standard of Living down

Environmental Impacts?

Substandard air quality

Water supplies cannot sustain natural life

Climate change n –hexane exposure

Teams Compete

RobotRick Enterprise

Control PCBA Outsourced to China

Foreign labor cost 50% of US labor

$50 per ea. from China

$59 per ea. from US

10,000 unit monthly volume

Evaluate Supply Chain Alternatives

What Is The True Cost?

What doesn’t flow to the Purchase Order

Price but is still a cost we are paying?

Supply Chain Digest News

Total Landed Cost Calculation

Key to Supply Chain Optimization

Still Immature Practice, 2010 3PL Study

Finds

Only 45% Report Extensive Use; 41% report Somewhat Use;

Data Capture Challenges - Primary

Obstacle

Oct 2010

Poll – 2010 15 th Annual 3 rd Party

Logistics Study

A.

Data Not available

B.

Do Not Have Right Tools

C.

Insufficient Time for Analysis

D.

Not Sure how to calculate TLC

Least Total Cost the total cost of a landed shipment including purchase price, freight, insurance, and other costs up to the port of destination. In some instances, it may also include the customs duties and other taxes levied on the shipment.

BUT – Is there more to know?

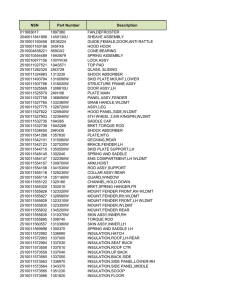

Total Landed Cost Example

Quoted price per board

Export packaging

Ocean freight

Marine insurance

Supplier price

Port of entry handling

Customs duties

Customs brokerage fee

Inland ground transportation

Inventory

Communications

Travel

Administrative

Additional cost

Total Landed Cost

Malaysia

50.00

1.00

2.20

0.26

53.46

(CIF Los Angeles)

0.80

2.14

0.25

1.25

3.12

(8 weeks)

0.16

0.63

0.60

8.95

62.41

USA

59.00

-

-

-

59.00

FOB Origin

-

-

-

0.80

0.86

(2 weeks)

-

-

1.66

60.66

0

Example – Circuit Cards

Circuit Cards Risk

10,000 units produced per quarter,

75% in transit – Boat

25% already arrived

$110 each! $1M

Immediate Engineering Change

Implemented, Rework = 100%

Circuit Cards Risk

Required assy’s to ship product

Takes too long to return

Non Standard Labor

Reassigning allocated skills, stopped other important work

Allocate limited supply of new parts,

Rework in US and New Build in China, costly expediting

Example – Forged steel Parts

Forged steel Parts

Volume Low - weekly demand

Quality Requirement is very high

Lead Time from US = 2-4 weeks

Lead Time from China = 8-16 weeks

Inventory at risk increased 4x

Forged steel Parts

Over half of items outsourced ultimately cost MORE.

Quality problems increased

Significant incidents reduced OTD

Some product returned, added freight

Some reworked locally when possible, added labor

Example – Mechanical Steel Fab

Mechanical Steel Fab

Power Supply designed by US team, manufactured by CM in China

Assy at 2 nd CM in China for Assy & Test

Quality Management System ignored

Defects set aside at Assy CM, piling up in informal “MRB” area.

Assy Contractor ran out of usable PS’s as defect rate from Contract Mfg grew.

Mechanical Steel Fab

“Escapes” found their way to customers.

Production Stopped.

Intransit inventories quarantined

Triage sort & ship process set up in

Bonded Warehouse.

Return majority not usable

Weeks to recover AFTER quality defect root cause identified.

Poll – Results

A.

Data Not available

B.

Do Not Have Right Tools

49%

48%

C.

Insufficient Time for Analysis 31%

D.

Not Sure how to calculate TLC 27%

Too busy working ON the business to work IN the business!

Too busy driving to stop for gas!

What If?

Lean Supply Chains

Supplier

Relationship

Management

Lean

Enterprise

Customer

Relationship

Management

Supply Chain Management is a core competency

On Shoring Instead - 2011

GE Water Heaters

Local collaboration saves cost, US 6% less than China – 400 Jobs returned

Hydraulic Die Cutting process

Custom Order Warranty Cost reduced 90%

Master Lock productivity increased 6x

Returned mfg from overseas

China Labor Cost Rising

Boston Consulting Group Press Release from May 5th, 2011;

“We should expect net labor costs for manufacturing in China and the US to converge by around 2015.”

Daily Supplier Dashboard

Minimize Risk, Minimize Variation!

Manage the Leading Indicators

FPY – First Pass Yield

Inbound Materials Certified

Daily “MRB” resolution, no laggards!

Track / Improve Response Time

Daily Quality Reporting by SN/item

Common Data Base

Timely CARs, Corrective Action Reports

Current

Position

Identify Value

Streams

Promote Education

Lean

Supply

Chain

Create

Flow

Leverage

Pull

Seek

Perfection

Motion

Over production

Defects

Waiting seven types of waste

Movement

Inventory

Poor processing

Specify

Value

Supplier

Relationship

Management

Lean

Enterprise

Customer

Relationship

Management

Supply Chain Management is a core competency

Benefits?

The World Class Imperative

Business

Strategy

Supply

Chain

Capabilities

Market

Leadership

Profit

Advantage

75%

Higher

Profits

*

15.0

10.0

12.2

Total Supply Chain Management Cost

13.1

11.3

10.3

10.9

7.1

6.7

5.8

7.0

6.1

5.0

6.5

Best

Avg

11.5

0.0

C omputers Industrial Telecom C hemicals Packaged

Goods

*Supply Chain Management Review, Survey of 110 companies in five sectors

Overall

Call To Action

List Three Things To Do Next Week

What are you measuring?

TLC as The Metric?

Who Collaborates on data?

Balanced Scorecard & Daily Dashboard

Questions? Ideas?

Summary - Key Takeaways

Elements of lean supply chains must include Total Cost view.

Apply 5 principles of lean

Systematic lean leadership =

Participation and Education

End of Presentation

How to Reach Us

Bob Forshay,

CPIM, CIRM, CSCP, CSCA, CSCM, CLM

VP, Transformance Advisors

Inc.

720-244-0579 c

720-295-LEAN bforshay@emailTA.com